Home > Automation technology > Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet has established itself as the communications standard for factory automation. Vehicle manufacturers and suppliers have been demonstrating the practical suitability of industrial Ethernet-based data exchange for a number of years now. This communication technology is now ready for use in the process industry: Turck is making S2 system redundancy fit for IP67 and IP69K.

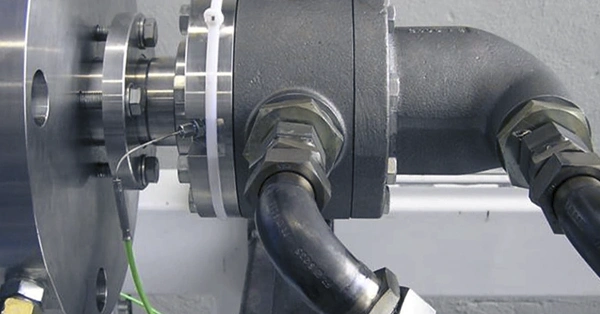

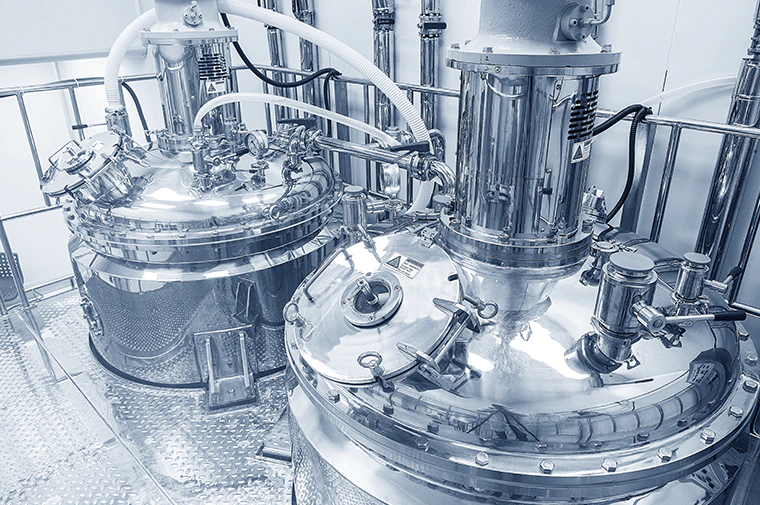

Developers of plants for the chemical and pharmaceutical industry bear a great deal of joint responsibility for ensuring the greatest possible availability of their customers’ production infrastructure. They must always bear in mind that interruptions to the production process are extremely costly. If the plant operator’s ability to supply goods is compromised, it risks a loss of custom and damage to its image. A further challenge faced by the designers of processing plants is the handling of hazardous substances in liquid or gaseous form: safety takes top priority. This is especially important in areas subject to explosion protection.

System redundancy is indispensable – but what form should it take?

In order to increase reliability, plant manufacturers design controllers and IO modules in the field with redundancy. Should a device or a connection fail, a backup system takes over the function in question. System redundancy must be guaranteed both physically and within the programming logic. The extent to which it is to be implemented depends on the requirements for the availability of the plant.

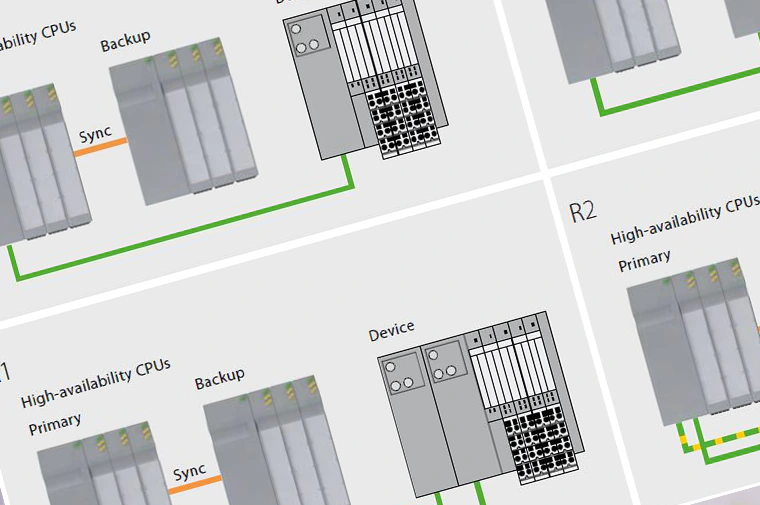

Categorisation: no redundancy to maximum redundancy

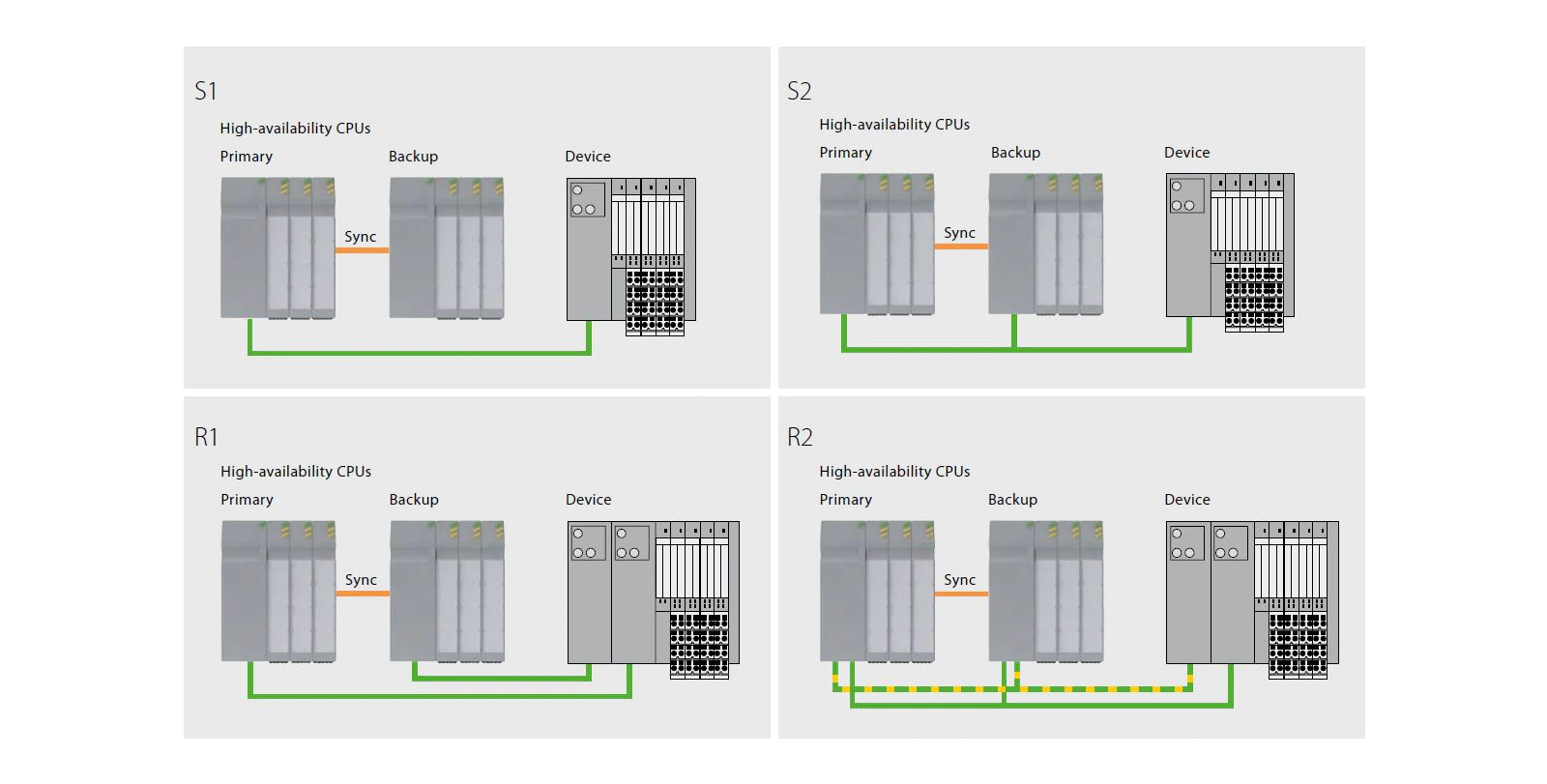

- S1: Classic Profinet design without redundancy.

- S2: Physical redundancy at the level of the controller, plus logic redundancy at the level of the field devices. There is a communications link for both the primary controller and the backup controller.

- R1: Physical redundancy at the levels of the controller and the field devices.

- R2: Logic and physical redundancy at the levels of the controller and the field devices.

Preferred category: S2 system redundancy

With category S2, should the main controller fail, the system will automatically switch to the twin. The IO system and the IO module in the field maintain the logical dual connection to two controllers. These can even be in two separate physical locations. S2 system redundancy is a useful solution for many applications and is therefore popular in plant construction.

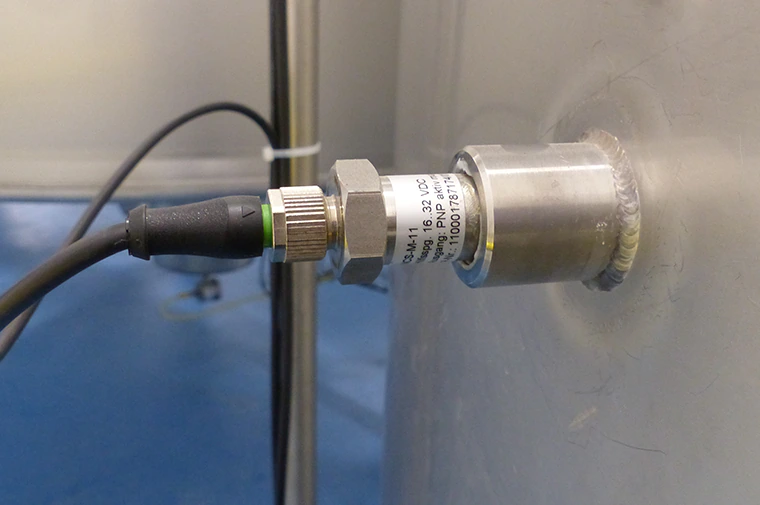

The TBEN-L5-8IOL IO link master module: a milestone for IP67/69K

Redundant infrastructures are nothing new. However, they were previously lacking an IO link master that could be used directly within the plant without the need for any additional protective measures. Turck has now closed this gap: the newly developed TBEN-L5-8IOL IO link master module supports S2 system redundancy and, thanks to its fully encapsulated electronics, it also meets the stringent requirements for IP67 und IP69K protection. Thanks to the combination of industrial Ethernet and IO link with such a high degree of protection, digitisation right through to the final yard has, for the first time, become a reality, and all without the need for a control cabinet – a true innovation.

As an additional innovative feature, the multi-protocol function of the Turck IO modules makes it possible to simultaneously communicate with TCP/IP with subordinated priority using the same cable as Profinet. This is used, for example, to provide read-only access to device data. This creates the ideal environment for condition monitoring, asset management and predictive maintenance.

Increased flexibility for plant design

The high degree of protection provided for the TBEN field devices makes it much easier to design plants for the chemical and pharmaceutical industry. Network architectures can be designed in a decentralised or modular manner. This reduces the amount of space required in the control cabinet.

Further exciting prospects in the area of system redundancy

The TBEN-L5-8IOL IO link master module is just the beginning. It marks the start of a Turck initiative to introduce S2 system redundancy into other product groups. This year, the leading automation specialist is also supplementing its range of multi-protocol devices with an S2 extension. Next in line are block modules from the TBEN family of products. IO systems for the control cabinet for the FEN20, BL20 and excom families of products are also in the pipeline. Bachofen is keeping a close eye on this to ensure that plant manufacturers do not miss out on any innovations.

Discover more products from Turck

Areas of application

-

Chemical and pharmaceutical industry

-

Pigging technology

-

Power plant technology

-

Process technology

Other focus topics in the area of chemical, pharma and food

Uniformity in diversity: the Turck family of fluid sensors

The world of fluid sensors is bewilderingly wide and diverse. There are countless types, features and designs that make it hard to choose the most suitable component for the...

Turck Ethernet Gateway for excom: make way for ethernet in the ex zone

The use of Ethernet in EX zones within the process industry was previously impossible due to safety issues. But now Turck has made a breakthrough with its GEN-3G Ethernet...

Transporting liquids: seeking the eco-friendly solution

The strict hygiene requirements in the industrial food production sector applies across the entire production chain. A key area of interest right now is also how to minimise your...

Sprinter in ISO Class 3: CSKR cleanroom actuators from THK

Avoiding particles when automating clean room processes is a top priority. With moving machine parts in particular, this key requirement is not that easy to meet since friction causes...

So nothing flares up in production: TSM temperature sensor from Anderson Negele

Process reliability is the top priority in the food and pharmaceutical industries. Disruptions affect producers’ ability to supply and can damage their reputation. Much depends on the reliability and...

Smart and alert: the COBOTTA compact robot

Due to space limitations, the use of robots often proves difficult. Programming is also a critical factor since, depending on the manufacturer, it can be a very lengthy process....

Reliable final inspections: eagle-eyed error detection

Packaging and labelling processes used in the food industry are mainly geared towards processing materials quickly. Final inspections take even greater precedence. These must be performed without any hitch...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Reliable means safe: ATEX-certified rotary joints

Due to the friction they create, rotating connections form one of the hazard sources in explosion-risk areas, such as in the chemicals and pharmaceuticals industry. The pre-conditions in gaseous...

Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet has established itself as the communications standard for factory automation. Vehicle manufacturers and suppliers have been demonstrating the practical suitability of industrial Ethernet-based data exchange for a number...

Product identification: no cakewalk in the food industry

An identification system’s true value becomes most apparent when it is subjected to demanding general conditions. These are particularly challenging in the food industry. Due to its resistant properties,...

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

No risks in the control cabinet: the IM18-CCM control cabinet motor from Turck

Unplanned machine and system downtimes are a costly irritation for producers in the food, beverage and pharmaceutical industries. The cause can often be found in the control cabinet, which...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Meets the standards and remains ecological: Parker Legris Liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Measuring on the tank instead of in the tank: precision load cells from Anderson-Negele

Measuring content in process containers with complex shapes or in horizontal positions is not straightforward. Depending on the tank design, using conventional sensors for fill level measurements can lead...

Keeping an eye on the tank: L3 pressure transmitter from Anderson-Negele

If you cannot see what is going on inside tanks in food or pharmaceutical production, the processes are almost impossible to control. To ensure process reliability, the tank contents...

Integrated inline in the process: moisture measurement with Liebherr sensors

Traditional methods of moisture measurement may be justified in non-automated processes. However, these are rarely suited to use on production lines. Liebherr moisture sensors are very different. These function...

Universal I/O: Seamlessly from Ex to non-Ex

Decentralised I/O systems are becoming increasingly widespread across the chemicals and pharmaceuticals industry. Data transfer from explosion-risk process areas, high availability and accurate diagnosis and identification of fault sources...

Hygienic design: consistent down to the smallest connector

When constructing plants for industrial food production, every single detail needs to be considered when it comes to hygiene, and connection technology is no exception. Turck provides two product...

Hygienic valve technology: in accordance with all norms and standards

Valve technology ranks among the particularly demanding aspects for industrial food production plant. Valves usually have many standards and norms to fulfil in addition to the high, purely functional,...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Giving bacteria no chance: aseptic angle valve 6051 from Schubert & Salzer

Compliance with the strict hygiene standards of the food, beverage and pharmaceutical industries is a constant challenge for designers of production infrastructures. Every single part counts. The type 6051...

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes...

Now remotely controlled by IO-Link: Positioner 8049 from Schubert & Salzer

In plant operation, personnel deployments on site may be time-consuming and awkward in some situations. This also applies to adjusting and maintaining control valves, which are often difficult to...

Modular alarm design in variations: K100 Pro Beacon hazard indicator from Banner

It is in the nature of industrial production that it is associated with safety risks. Where hazardous substances are involved in production and processing plants, potential risks cannot be...

The safe alternative to the Zener barrier: ATEX-compatible IMX12-SG strain gauge evaluation device from Turck

Strain gauge evaluation devices for use in ATEX zones are a rarity. The divide between ATEX and non-ATEX areas is particularly critical. With the IMX12-SG interface, Turck has unveiled...

Not a drop too much, not a drop too little: FMQ flowmeter from Anderson-Negele

Poor control of flow in production equipment pipelines will affect process efficiency and incur costs. The more accurate the measurement, the safer the production process. The FMQ flowmeter from...

Automated climate monitoring in the warehouse: Condition monitoring with Turck and Banner

When storing sensitive products, continuous temperature and humidity control is essential to prevent product losses. However, doing this manually requires a lot of effort. A complete condition monitoring solution...