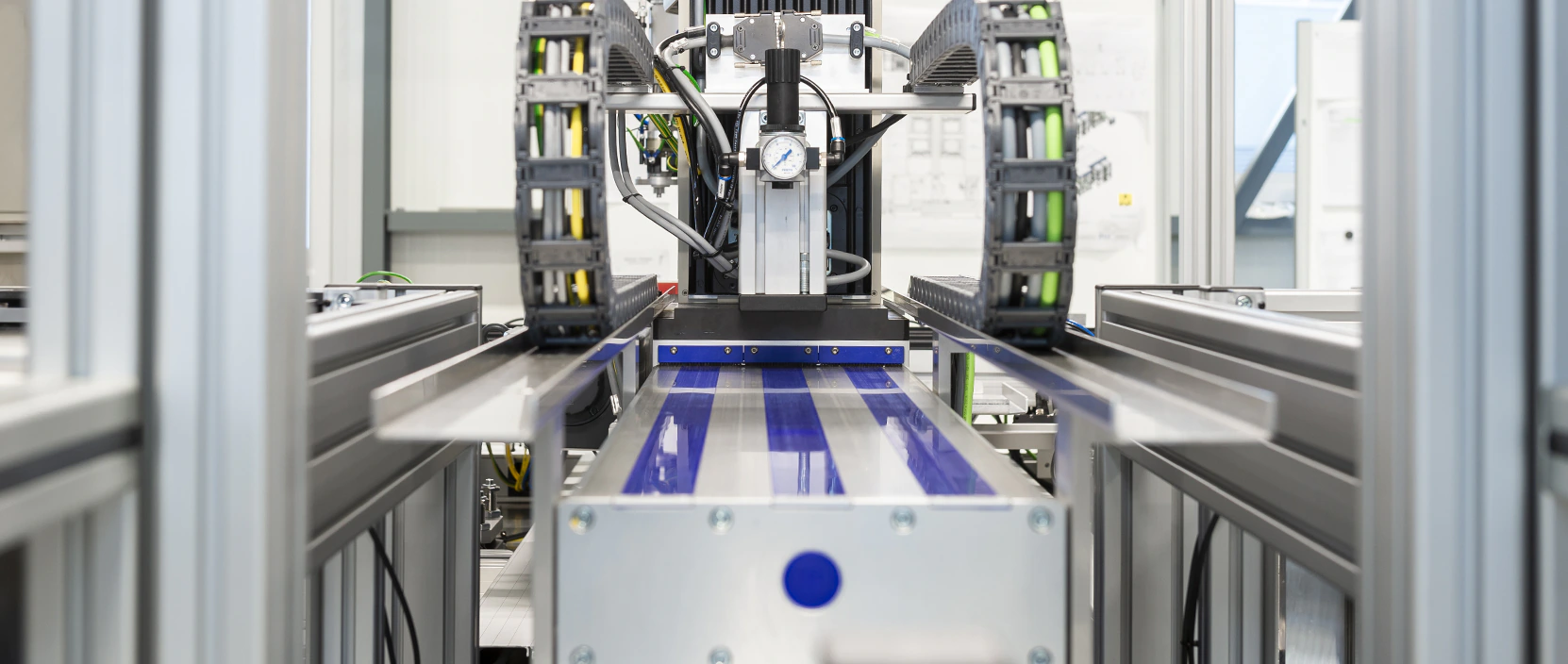

Stability, precision and speed – HSB axes in the new system design

The initial situation

Asic Robotics was looking for suitable linear axes for a new system design for producing and assembling automotive parts and turned to its partner for decades – Bachofen AG. The customer required axes which are suitable for large forces with a high level of precision.

Project requirements

- The customer from the German automotive industry wanted a linear system to guide the robots

- Stability and high precision at high speed

- Short and guaranteed delivery times

Bachofen’s solution

Working closely with Bachofen’s product management team, the key technical data was compiled at the start of the project. Based on the project requirements, it quickly became clear that an axis from HSB Automation with a ball screw drive would be suitable. The experienced industry product specialists created the appropriate axis design for the customer-specific cell modules on the transfer line. Thanks to short delivery times – despite current worldwide supply bottlenecks – custom-made HSB-delta® compact linear units and HSB-beta® mechanical linear units could be installed just a few weeks later. The precision and stability, even at high speeds, impressed the project team in every way.