Home > Sectors & Solutions > Chemical, pharma, medical technology, food

Chemical, pharma, medical technology, food

Specialist knowledge is crucial to your success. Our global network also gives us access to an extensive range of high-quality products.

Medical technology, chemical, pharmaceutical, food industry – and Bachofen. Together we are a perfect team. Both in the planning and development of complex systems and in the dimensioning and optimisation of existing production systems. In addition to personal advice and the sale of top-class standard products, we develop solutions for you that are precisely tailored to your requirements and the applicable standards. What we want: Safety and stability for your processes. We act quickly, clearly and in a straightforward manner. We deliver tested, certified components on time, support you with the necessary documents and create unique process quality through our professional quality management. Rely on our expert knowledge and on our commitment.

Do you have any questions?

Reference projects

Safe connections in the hose station: RFID with an extra twist at B. Braun Medical AG

"Bachofen is not only a distributor of products, but also a provider of technical expertise. The fact that we were also able to benefit from Bachofen's engineering expertise was an extremely positive experience. Extra services like this really make the difference between a seller and a partner".

Thomas Mühlebach, Head of Maintenance and Technology at the Sempach site, B. Braun Medical AG

Perfect water delivery for excellent coffee

«Bachofen very quickly presented three proposals and impressed us with expertise and reliability the whole way through.»

Peter Bayer, CEO, Aequator AG

Plant construction and engineering from SPE Tech – what else?

«In addition to the technical know-how and flexibility of our supply partners, the price also plays a decisive role in a successful collaboration. As a matter of principle, we work with a small number of suppliers that we know well.»

Adrian Brunner, Senior Project Manager

Cleanroom specialist SKAN – a shining example in isolator construction

«Our motto of always being one step ahead together also applies to the collaboration with our supply partners. Bachofen supports us with technical know-how in the development of future-oriented solutions.»

Matthias Hauber, Project Manager Industry

CHF 60,000 per year saved by using the right sealing heads

«We received competent and uncomplicated advice. We are very satisfied with the solution.»

Patrick Marquis, Head of Maintenance Wahlenstrasse

Estavayer lait SA dairy: a prime example of food safety

«We have found Bachofen to be a flexible, fully committed partner who won us over with their long-term cost-benefit calculations of a CIP solution with Schubert & Salzer valves.»

Nicolas Roulin, Head of System Maintenance

Developing sustainable protein sources: Bühler Insect Technology

“The insect industry is still in its infancy. That is why we rely on partners like Bachofen in developing these facilities; partners who don’t want to fob us off with standard products, but who are ready to put time, creativity and their heart and soul into a project.“

Nicolas Braun, Bühler AG, Business Development Manager Insect Technology

Hulling made easy: with efficient technology from Bühler

«Bachofen took care of the ATEX certification of the linear position sensor despite the small order quantity. That’s what we call partnership. Other providers wouldn’t or couldn’t help us in this matter.»

Vincent Behrens, Project Manager

The fully automated laboratory is reality: liquid handling with Andrew Alliance

«Initially, Bachofen was just one of our many suppliers. But during our cooperation we soon noticed significant differences that manifested themselves in the proximity, availability, speed and professionalism of the Bachofen team.»

Julien Pache, Production Manager

Product categories

Bachofen is your competent partner for a wide range of applications in industrial automation. Benefit from the experience and expertise of our employees – we are happy to advise you personally.

Focus topics and technologies

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

Automated climate monitoring in the warehouse: Condition monitoring with Turck and Banner

Concrete application examples

Cleanroom environment

In cleanroom environments, ISO3/ISO5-certified robots which are not only fast, precise and compact but are also resistant to aggressive sterilising agents and are easy to maintain are used.

Overflow protection in laboratory diagnostic machines

The overflow protection in laboratory diagnostic machines is provided in a contactless and contamination-free manner by capacitive sensors.

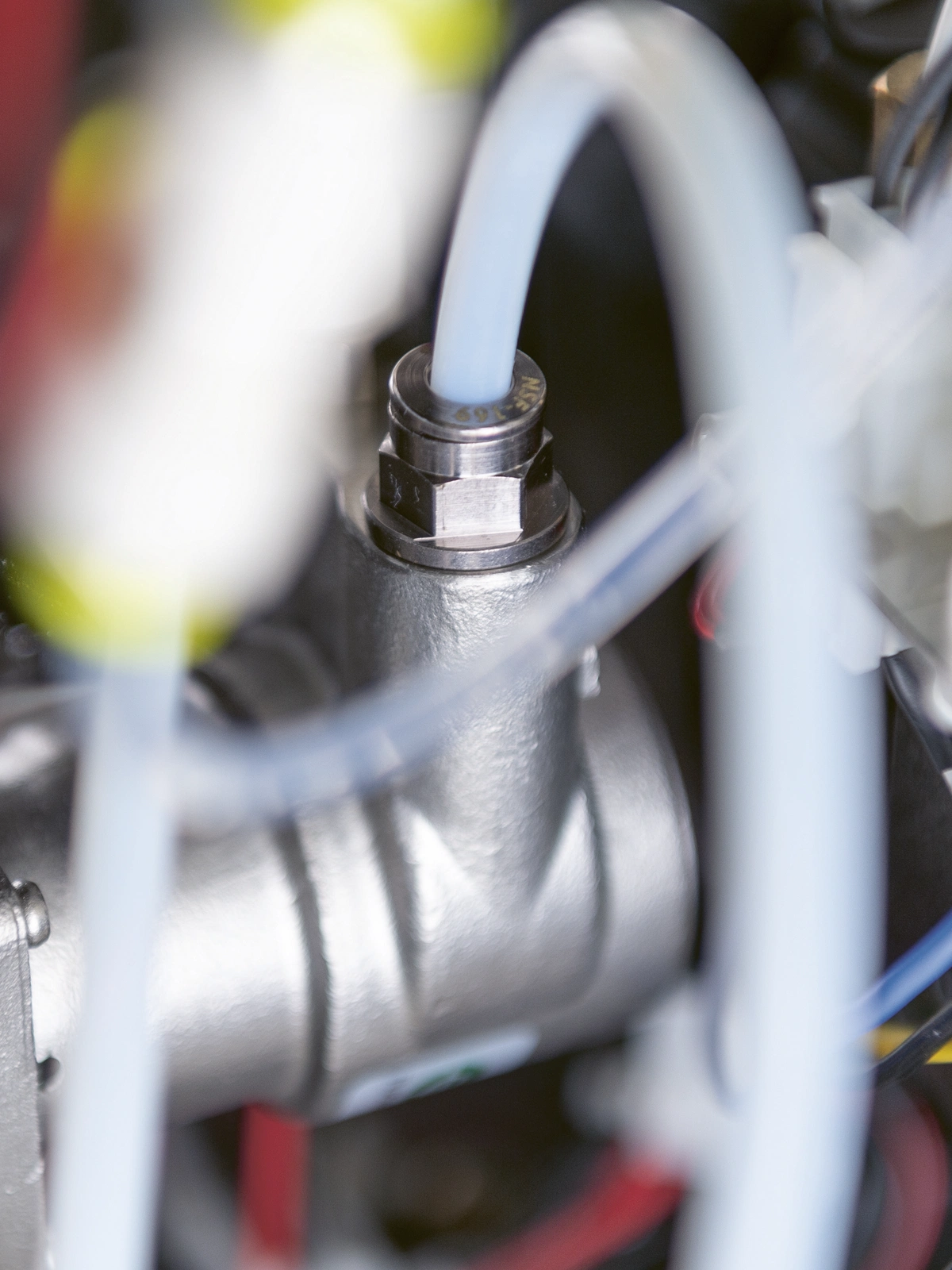

Connections for air, liquids and inert gases

Certified plug-in connectors and leak-free coupling systems ensure maximum purity with connections for air, liquids and inert gases.

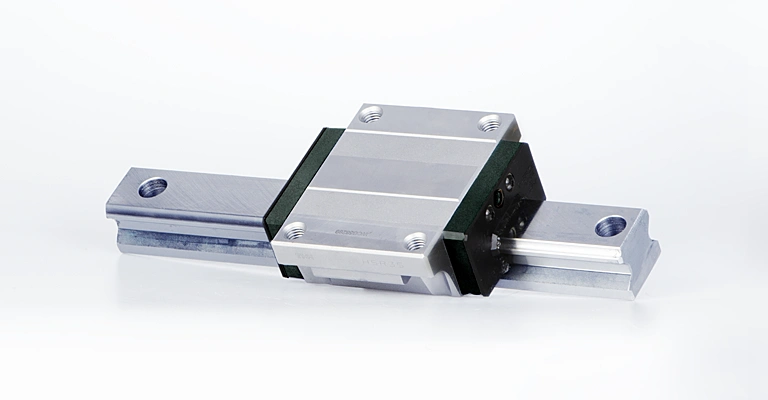

Compact miniature guides in pipetting machines or other laboratory equipment

Use of light and particularly compact miniature guides in pipetting machines or other laboratory equipment; the caged ball technology ensures extremely low particulate emissions with significantly increased permission load and service life.

Cooling of rollers for chocolate production

Reduction in energy consumption by optimising the process temperatures with heat exchangers, for example when cooling rollers for making chocolate.

RFID identification systems

Management of shelf lives and cleaning intervals for various products and intermediates by means of RFID identification systems.

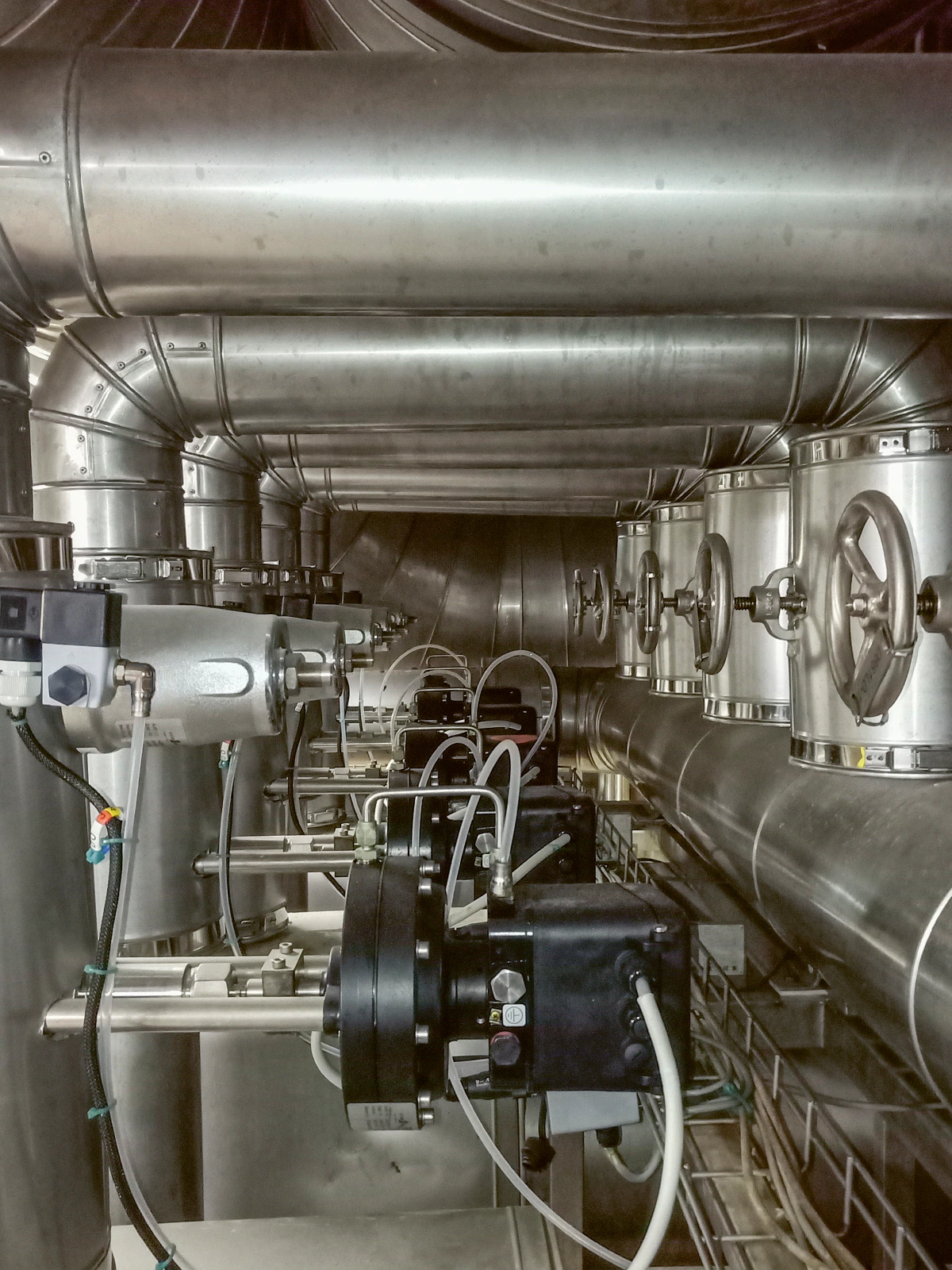

Connection technology in the process industry

Maximum control and easy maintenance through the use of coded connection technology in the process industry.

Explosive area

Use of lebel measurement in explosive area.

Temperature and humidity control via wireless communication

Optimum monitoring and control of temperature and moisture in greenhouses using wireless communication.

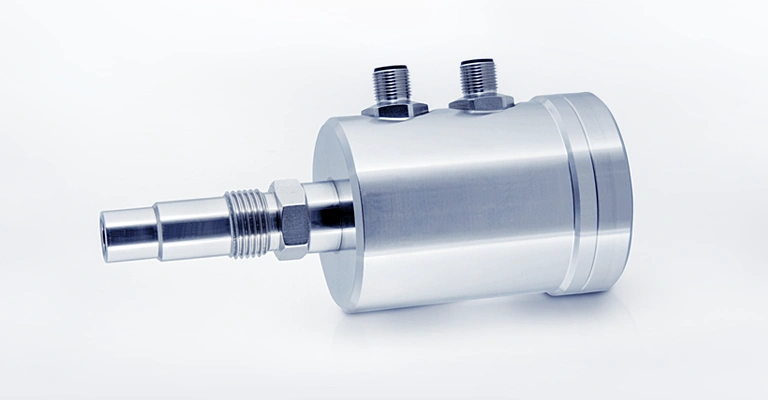

Metered addition of gases, vapours and liquid media

Metered addition of gases, vapours and liquid media in a wide range of different processes by accurate and reliable sliding gate valves.

Our expertise – your benefit

- Compliance with the required standards and guidelines in the area of hygiene, safety, environment

- Long lifetime thanks to high-quality materials

- Guaranteed safety thanks to ATEX approvals

- Standard components matched to customer requirements

- Custom-made products: multifunctional, space-saving, user-friendly, ready to install

- Durable components for challenging conditions

- Preventive maintenance thanks to optimised control technology

- Compliance with the highest purity requirements

- Simple validation

- Optimised process management using RFID systems