Safe connections in the hose station: RFID with an extra twist at B. Braun Medical AG

During the mixing and filling processes of medical products, faulty hose couplings have fatal consequences. B. Braun Medical AG is using RFID in its new plant at the Sempach site, integrated into the hose couplings themselves.

Until the 1850s, cleanliness and disinfection were not seen as an issue in medicine. This changed in 1847, when a doctor named Ignaz Semmelweis was able to prove with a study that disinfection significantly decreases the transmission of diseases.

In the 21st century, the topic is more relevant than ever. The demand for infection prevention products in hospitals is huge and will continue to grow. B. Braun Medical AG plays an important role in this expanding market across the globe. At the Sempach site, the renowned medical technology company produces a wide range of disinfection and hygiene products as well as products for treating chronic wounds. In response to the sharp increase in demand, B. Braun Medical is in the process of doubling its production capacity.

Identification ensures safety

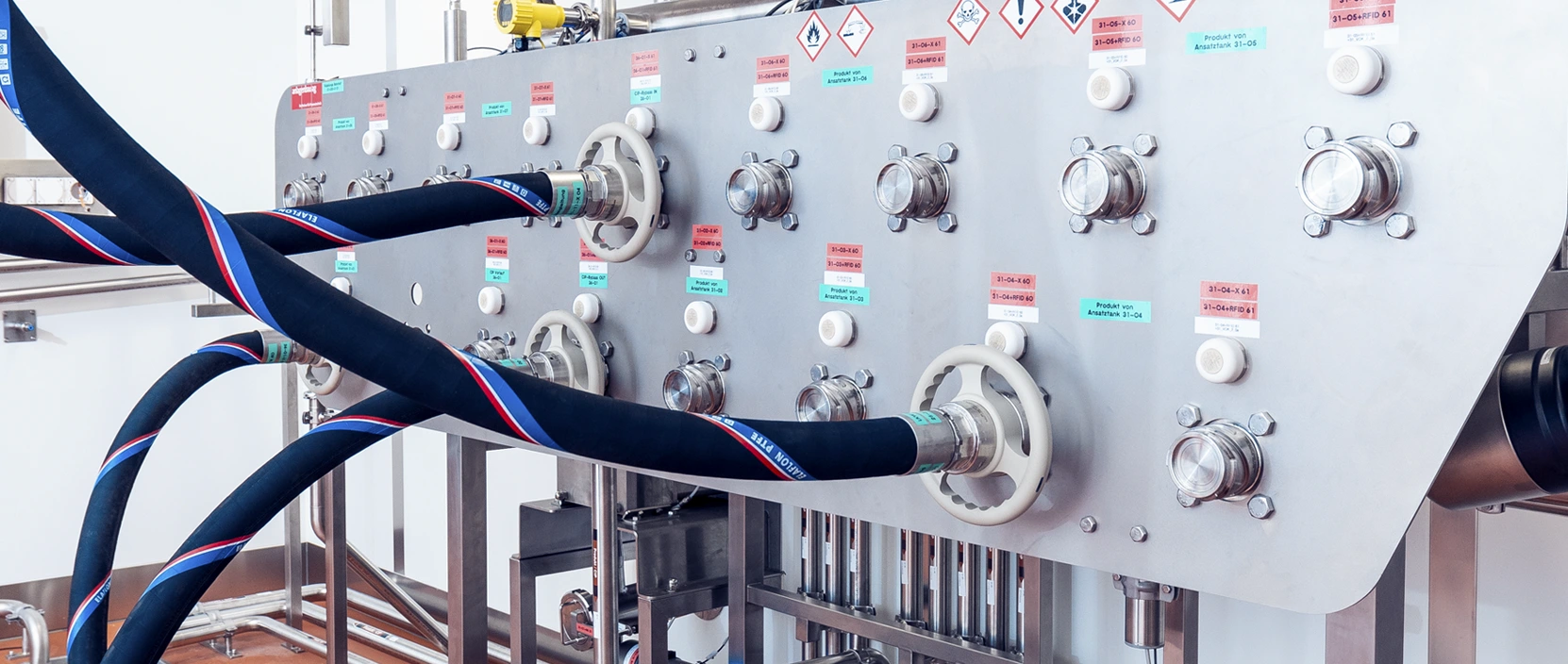

The core process of the new plants essentially comprises the supply of the various chemical raw materials from the weighing containers to the mixing tanks and the transfer of the finished products to the filling line. Intersections in the system are two hose stations, one of which is located at the loading station and the other at the interface to the filling line. During the process, the hoses must be transferred three to four times per batch. In order to avoid confusion, which might have disastrous consequences, the hose stations are integrated into the RFID system that controls the entire plant. For each connection, an RFID tag on the side of the hose and an RFID read/write head must interact with one another. The outlet only opens if the system has identified the correct medium.

The communication-capable coupling wheel: Developed by Bachofen

There are a large number of hose couplings with integrated RFID tags on the market. However, a standard solution was not an option in this case due to limited space and heavy hoses – an opportunity for the creative minds of Bachofen’s RFID specialists. Bachofen’s vision: A hose coupling with a coupling wheel, into which the RFID tags are cast. Together with MannTek and Schudel AG – specialists in coupling technology and hose systems – Bachofen implemented the unconventional idea and developed a prototype, which impressed B. Braun Medical across the board. “The specialists at Bachofen really immersed themselves in the task and did not give up until a solution was found to which we were able to say ‘yes’ without any reservation”, explains Thomas Mühlebach, Head of Maintenance and Technology at the Sempach site. The final version of the rotary wheel contains three RFID tags inserted at intervals of 120°. When the coupling is screwed in, the signals of the RFID tags identify the connection in an instant and enable the flow if the result is positive.