Home > Products & Brands > Product range > Motion technology > Linear motion guides

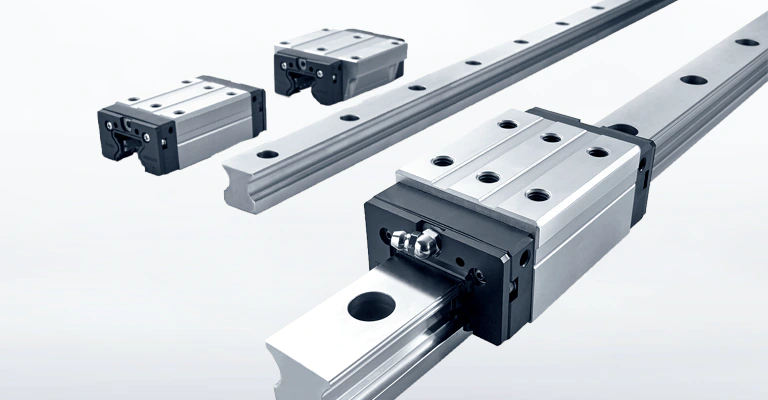

Linear motion guides

Also available on request

Also available on request

THK develops and manufactures high-precision linear motion guides components. The high quality and service life of the linear motion guides guarantees maximum equipment usability. Specialists in motion technology will gladly support you from development and the prototype phase right through to procurement and inventory management so that you are also securely positioned for the future.

- Guides with caged ball technology: low-maintenance, dynamic, quiet, optimal running properties

- Rolled ball screws according to DIN, with and without finished ends as per customer drawings

- Various linear motion guides available quickly and cost-effectively from the Uster warehouse

- Highly rigid and compact cross roller bearings for the most demanding requirements, force absorption in all directions

Linear motion guides HDR

- High stiffness in MC directionthanks to O-arrangement of the running grooves

- Available with masking tape

- No groove for mounting of the masking tape required

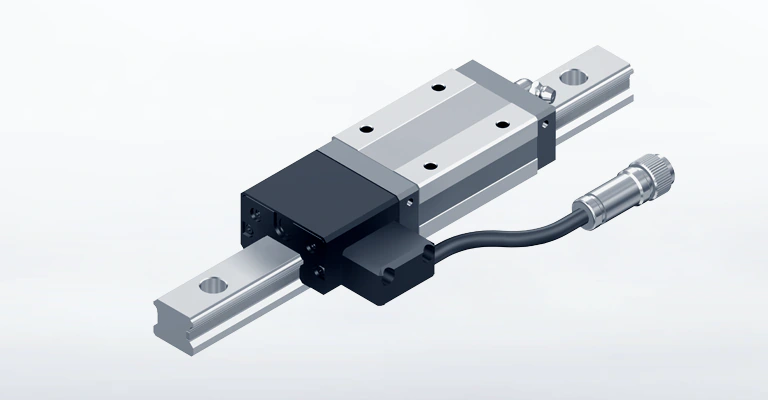

Linear motion guides SHS-LE

- SHS LM Guide with globally standardized dimensions and THK linear encoder as a unit

- Reduction of construction and assembly time

- Less space required - more compact designs

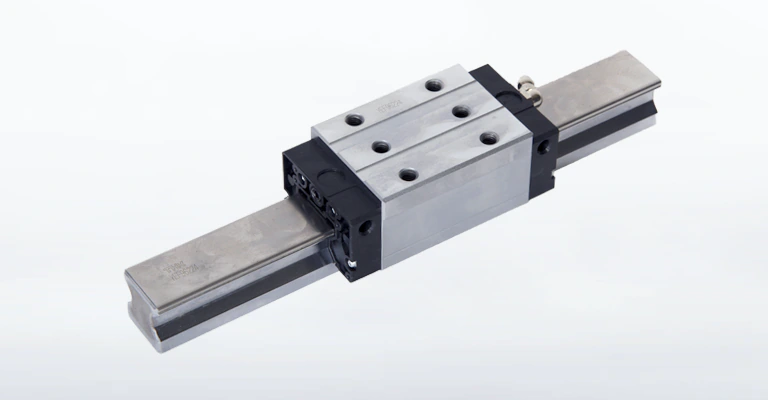

Linear motion guides HRX

- Extremely high rigidity thanks to the use of rollers as rolling elements with very low deflection

- Equal basic load ratings in the radial, reverse radial and lateral directions

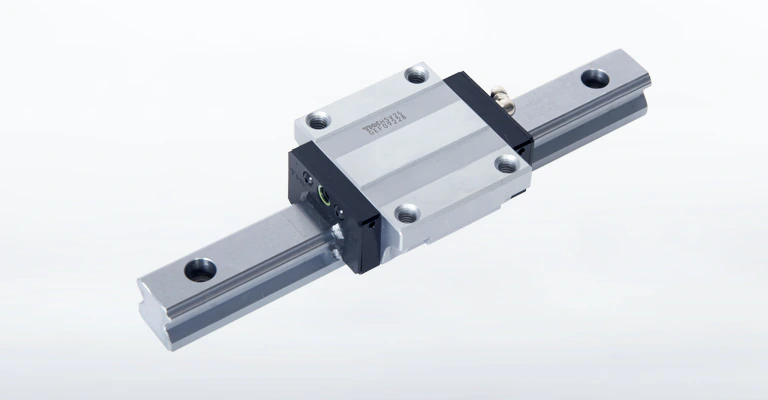

SRS Miniature guide

- Ball chain technology

- Rustproof design

- Compact miniature guide with long service life

HSV-Affordable

- Standardised model

- Affordable in its class

- Cart and rail interchangeable if required

- Available from the Uster warehouse

SRG-Highly rigid roller guidance

- Maximum load-bearing capacity

- Consistent load rating on all axes

- Very smooth running performance without the rollers skewing

SHS-Allrounder

- Simple uncomplicated assembly

- High level of rigidity due to preload

- Continuous stable linear movement

HCR-Curved guide

- Backlash-free circular motion

- High degree of construction flexibility

- Shorter assembly time

- High-precision guidance

Reference projects

Zubler Handling AG

Linear motion guides

Mikron Automation

Linear motion guides

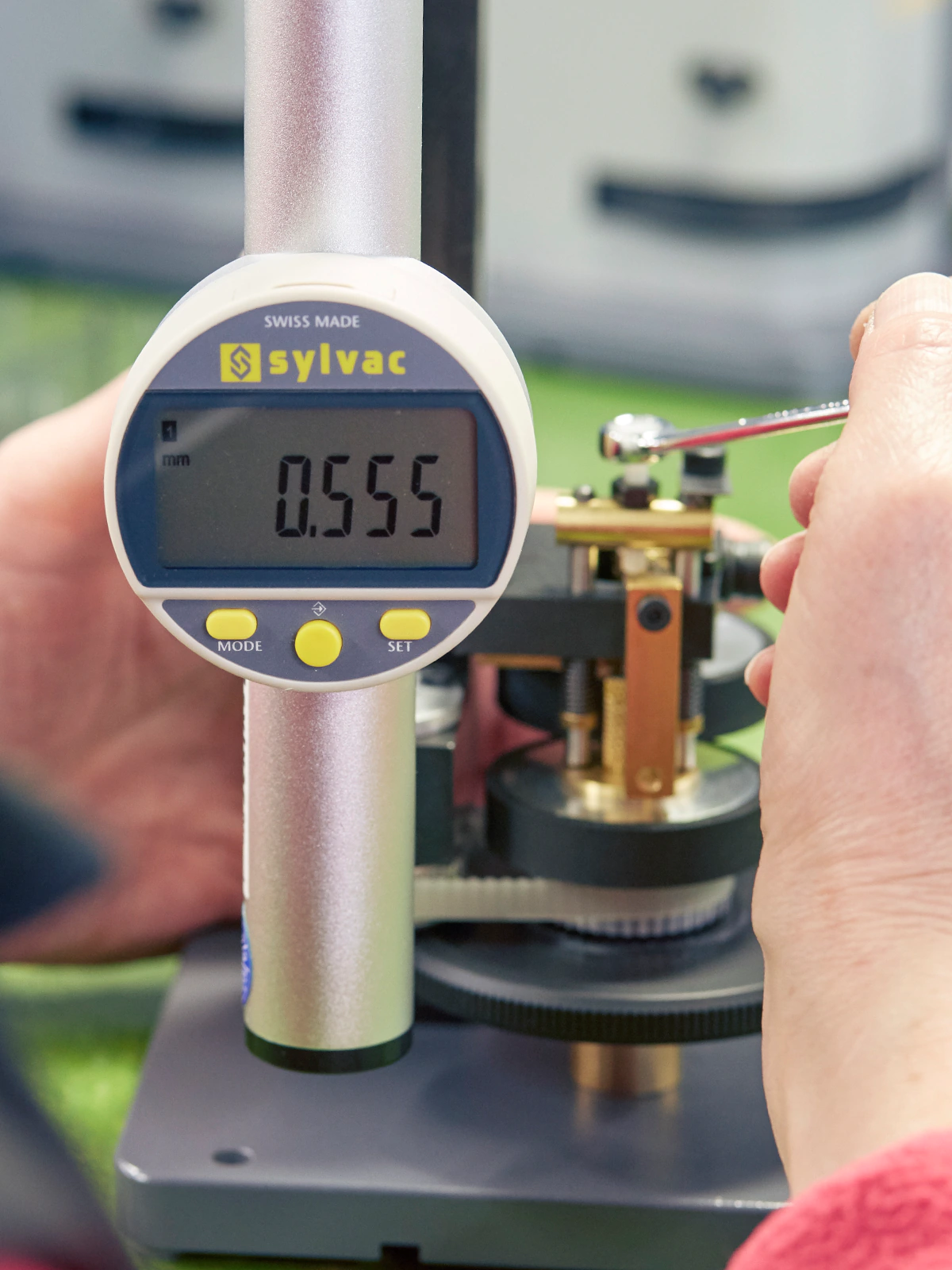

Sylvac SA

Linear motion guides

Willemin-Macodel

Linear motion guides

Zubler Handling AG

Linear motion guides

Rekordhalter in der Nische: Sondermaschinenbauer Zubler Handling

Es gibt Unternehmen, die jede sich bietende Opportunität im Markt wahrnehmen. Die Zubler Handling AG gehört nicht in diese Kategorie. Der Sondermaschinenbauer fokussiert sich seit Jahren konsequent auf seine Kernkompetenz. Mit nachhaltigem Erfolg

«Bachofen unterstützt uns in technischer Hinsicht und

setzt sich vehement für die Verfügbarkeit der von uns

präferierten THK-Komponenten ein. Das stärkt uns den

Rücken, damit wir die hohen Erwartungen unserer Kunden erfüllen können.»Remo Müller, Leiter Fertigung/Einkauf Zubler Handling AG- Developer

Mikron Automation

Linear motion guides

Mikron dreht auf – Partnerschaft als Erfolgsposition

Eine enge Zusammenarbeit mit den Lieferanten zählte bei Mikron schon immer zu den wichtigsten Geschäftsprinzipien. In einem zunehmend anspruchsvollen Marktumfeld hat diese Partnerschaft strategische Bedeutung erlangt.

«Die goldenen Zeiten, in denen der Schweizer Industrie der Erfolg in den Schoss fiel, sind endgültig vorbei. Wir müssen uns mehr denn je anstrengen, um unsere Kunden zufrieden zu stellen. Lieferanten, die ohne Wenn und Aber mitziehen, helfen uns dabei.»

Jean-François Bauer, Head of Marketing & Business Development, Mikron Automation- Developer

Sylvac SA

Linear motion guides

Sylvac Präzisions-Messtechnik – schon längst Digital unterwegs

Die Digitalisierung ist zurzeit das alles beherrschende Thema. Doch es gibt Unternehmen, für die das digitale Zeitalter nicht erst gestern begonnen hat. Zu diesen zählt das auf zukunftsweisende Messtechnik spezialisierte Familienunternehmen Sylvac SA.

«Unsere Lieferanten müssen dazu beitragen, dass wir heute und in Zukunft wettbewerbsfähig bleiben. Bei Bachofen schätzen wir die breit gefächerte technische Kompetenz, das spezifische Fachwissen und die hohe Reaktionsfähigkeit.»

Eric Schnyder, Geschäftsführer Sylvac SA- Developer

Willemin-Macodel

Linear motion guides

Willemin-Macodel: Trendsetter im Werkzeugmaschinenbau

«Grenzen sind dazu da, überwunden zu werden.» Mit diesem Leitsatz hat sich Willemin-Macodel im weltweiten Markt der Bearbeitungssysteme in eine führende Position katapultiert. Und übertrifft bei der Präzision, der Leistung und der Bewältigung von Komplexität immer wieder sich selbst.

«Ein innovatives Unternehmen wie wir es sind, muss sich ständig die Frage stellen, ’was können wir wie verbessern?’. Bachofen zählt zu den Lieferanten, die uns immer wieder mit neuen Ideen und technischem Input helfen, die richtigen Antworten zu finden.»

Oliver Haegeli, Co-CEO Willemin-Macodel SA- Developer