Powering the energy revolution: GRZ as a pioneer in hydrogen technology

The future of clean energy belongs to hydrogen – this conviction forms the backbone of the business model at GRZ Technologies. The young company is shaking up the market for hydrogen applications thanks to its environmentally friendly power-to-power solutions.

Ernst Adler, Chief Operating Officer at GRZ Technologies, refers to the metal carrier at the heart of hydrogen compression as a “magic material”. This alludes to solid-state metal hydrides, whose atoms absorb the atoms of the hydrogen gas supplied and trap them within their metal structure. What sounds complicated to the average person is actually ingeniously simple: This revolutionary technology allows the volatile hydrogen gas to be stored in compressed form and then released again, since the process is reversible. In downstream processes, the hydrogen can be used in many ways as a clean form of energy.

Turning technology into a business concept

Since the 1990s, Professor Andreas Züttel at the Swiss Federal Institute of Technology has been researching these connections and has laid the foundation for the industrialisation of solid-state hydrogen technology. This began with the establishment of GRZ Technologies in 2017. The startup’s first product was a compact metal hydride compressor for laboratory applications. Hyundai’s involvement as a shareholder shortly after the launch paved the way for larger-scale product developments. Initial development orders for HyCo* thermal compressors were received, further well-known strategic partners came along, and within just four years GRZ Technologies became a global player in the booming hydrogen technology market.

Ongoing development of new application areas

GRZ Technologies’ current solution portfolio is focused on containerised and modular DASH** solid-state hydrogen storage systems for environmentally friendly energy storage, in conjunction with DASH hydrogen-to-power modules for the decentralised storage of electrical energy. The company has achieved a major technological triumph in the field of hydrogen mobility with a system for the construction of off-grid hydrogen filling stations. A methanation reactor for the production of CO2-neutral synthetic methane, which can compete with biogas in terms of price, is about to be launched on the market. “We are pursuing ambitious goals and resolutely driving development towards a fully renewable energy management system worldwide”, explains Ernst Adler.

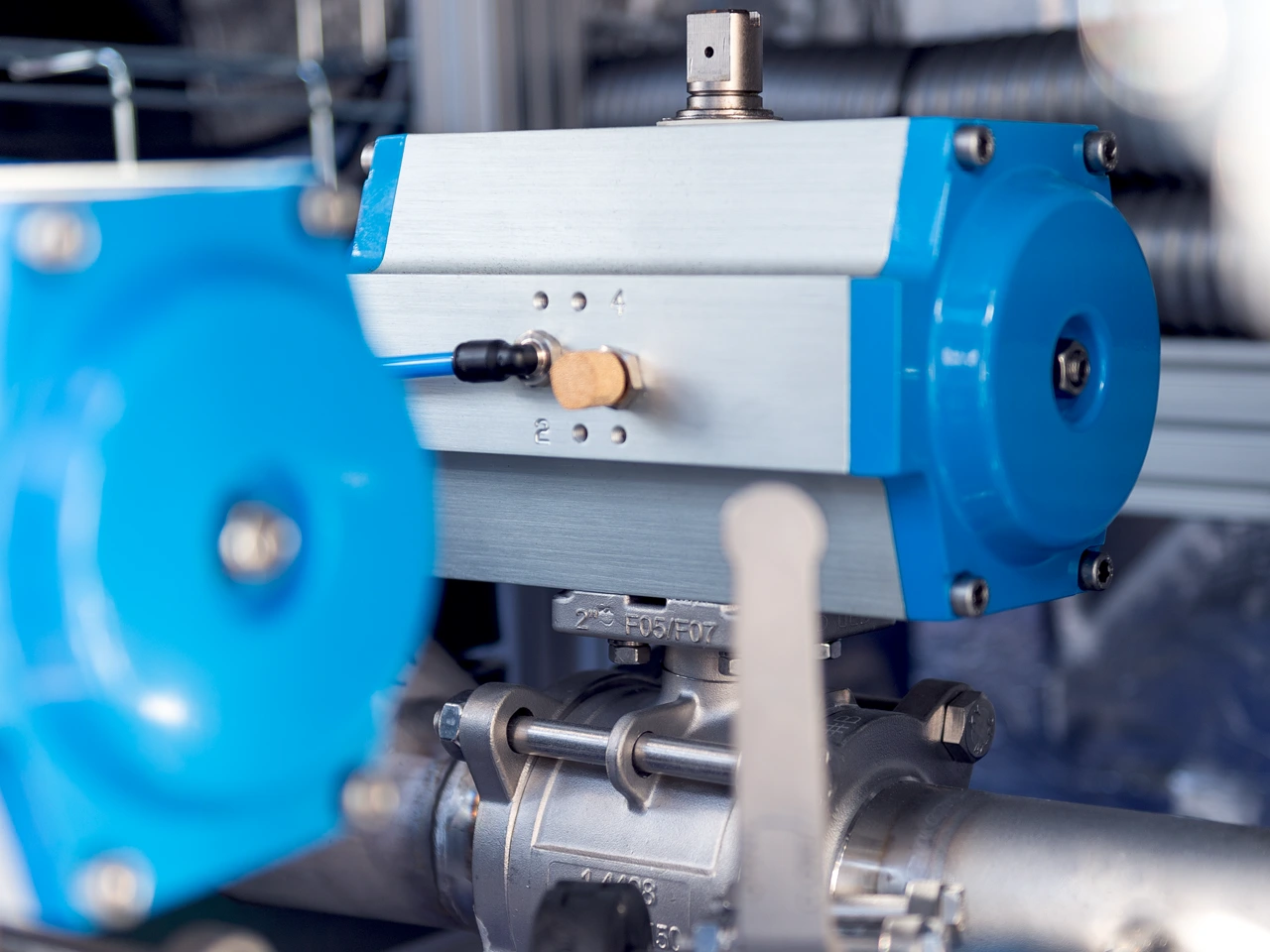

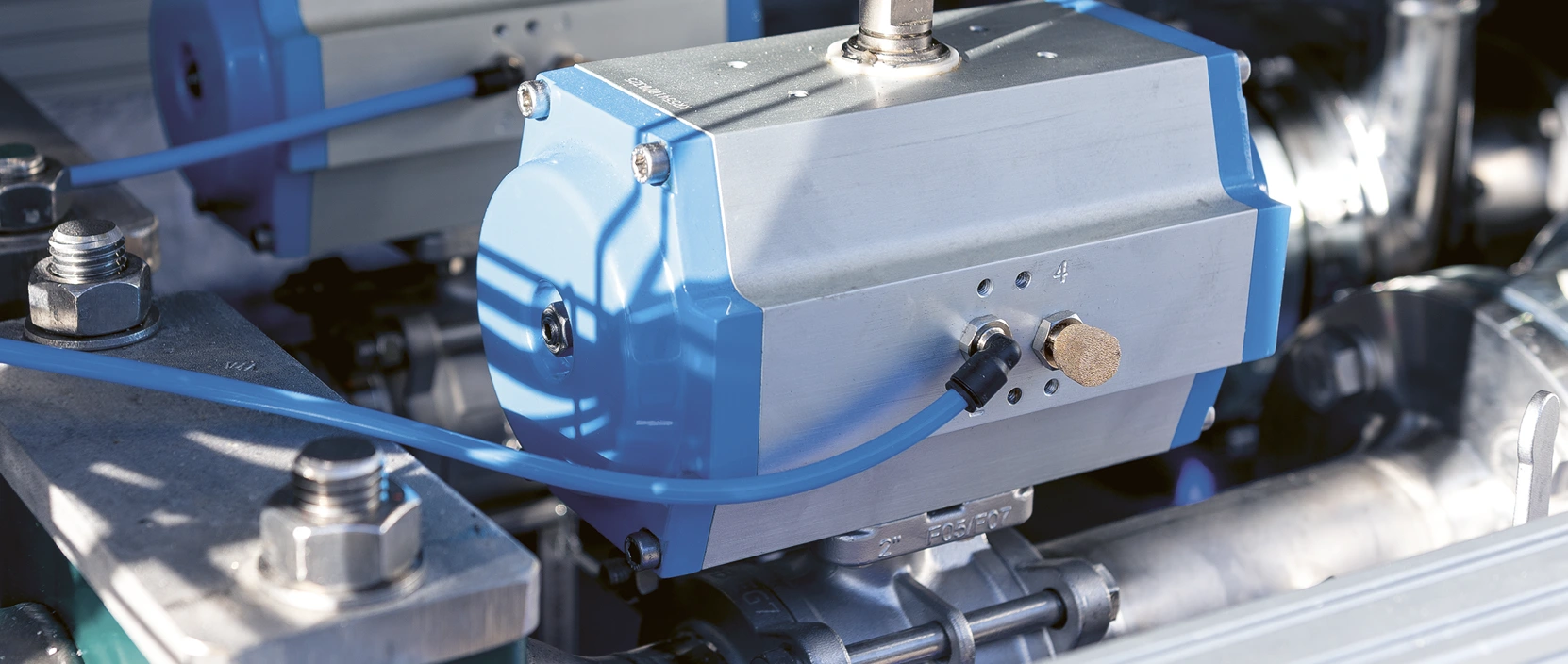

Added value in procurement via intermediate goods

Adler expects his supply partners to be fully involved and willing to provide intermediate goods. Bachofen supplies GRZ Technologies with high-precision valves from their technology partner Schubert & Salzer, while also providing the company with ready-to-install modules that have been designed according to customer specifications. An additional service provided by Bachofen is project-related bundling of supplies. Ernst Adler: “We need 30 to 40 different valve types, and these are provided by Bachofen in a format that is sorted and coded by system. We simply order the corresponding packages, which considerably reduces work preparation time during assembly.” In keeping with the corporate philosophy of GRZ Technologies, sustainability is also a key theme in terms of procurement. Bachofen meets this requirement thanks to its environmentally friendly packaging and optimised logistics with the smallest possible carbon footprint. “Anyone who wants to work with us must not only understand us, but also share our values”, summarises Ernst Adler. This message has been received by Bachofen.

* Hydrogen compressor

** DASH dense and safe hydrogen storage