Flexibility as an approach and design principle: Bending machine manufacturer Jorns

Just a handful of companies around the world have mastery over sheet metal bending technology. Bending machine manufacturer Jorns AG positions itself as a leader in terms of quality and has gained a unique standing in the market thanks to its flexible machine concept.

Roof and wall profiles made from sheet metal are immensely popular among architects, civil engineers and builders. The profiles are sustainable, durable and provide a functional aesthetic with an understated design that gives halls, factories, commercial buildings and residential buildings a distinct look. At one leading German vehicle manufacturer, the façades of the sales and service locations – which are structured with sheet metal profiles – are an important means of expressing the company’s identity. Like millions of other profile elements used in construction across the globe, these were bent on a bending machine from Jorns AG – a second-generation family-run business from Switzerland.

With passion and a love for innovation to global excellence

Focus on the customer and their specific requirements

“What our machines are capable of is one thing”, explains Head of Production Peter Roth, “but what makes them unique is the spirit built into them”. The Jorns team not only considers technical factors – they also put strong focus on the needs and wants of customers. “Power of Flexibility” – these are no mere empty words from the machine manufacturer, but a binding guiding principle for the company. This shapes the way that the company handles customer requests as well as the modular concept of the machine: Each machine can be configured according to individual specifications. A wide range of options allow each bending system to become a tailor-made solution.

THK quality and collaborative partnership with Bachofen as key factors for success

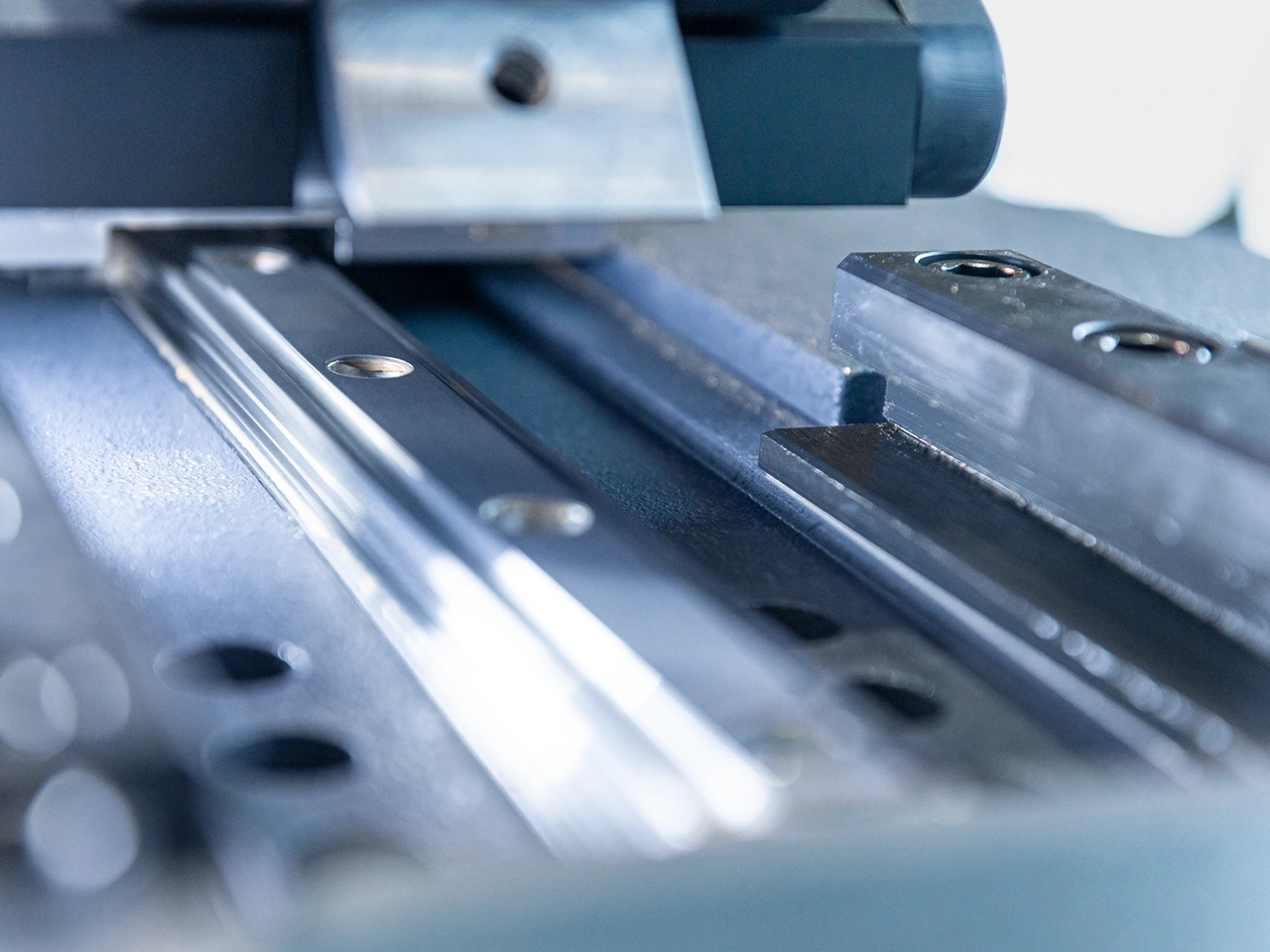

Jorns bending machines perform heavy-duty work at the highest level of precision and under extremely high force. Each component of the machine must contribute to this goal. This applies in particular to the linear guides on which the heavy bending beam and the shearing system of the machines move. Products from technology partner Bachofen and global market leader THK fully satisfy the strict requirements of the designers at Jorns. Peter Roth: “With THK, we are in safe hands. In addition, Bachofen is a partner there to support us with technical expertise and competent advice in the development of our machines. As a result, they make a substantial contribution to our market success”.

The long-standing relationship between Jorns and Bachofen is based on open communication, transparency and, last but not least, the shared belief that flexibility is the only way to overcome current and future challenges in the market. This belief is what unites the two companies.