Operational excellence: the SBB factory

Every day, Swiss Federal Railways (SBB) carries around 1.26 million passengers on its network spanning over 3,200 kilometres. This remarkable performance is made possible by an organisation that works behind the scenes unbeknownst to train passengers and the general public: the SBB Passenger Transport Operating division.

What is the service life of an InterCity tilting train or an SBB regional commuter train? At what intervals do the train types and units of Switzerland’s largest transport company have to be maintained? When is the overhaul of a 1st or 2nd class passenger coach due, of which SBB owns around 1,800? What requirements must the passenger train of the future fulfil? SBB’s Passenger Transport Operating division is tasked with finding answers to these and many other questions in connection with the maintenance and procurement of rolling stock. However, this is by no means its only job: the Factory, as this organisational unit is known, ensures that the vehicle fleet is safe and reliable on the rail networks in Switzerland and other European countries.

Broadly diversified service portfolio

In addition to the maintenance and repair of rolling stock, SBB Passenger Transport Operating arranges the deployment of the locomotive crew of 5,500 passenger trains daily, ensures the availability of the trains and is responsible for fleet procurement and strategic purchasing. The top priority here is quality. This is crucial regardless of whether they are dealing with

large projects or the purchase of a spare part. Raphael von Arx, system engineer for brakes and drives at the Fleet Technology unit of SBB Passenger Transport, describes the demands they place on quality: «You have to clearly define the specifications for a technical component and, above all, be able to estimate how long it needs to function.»

Door controls as a critical factor for railway operations

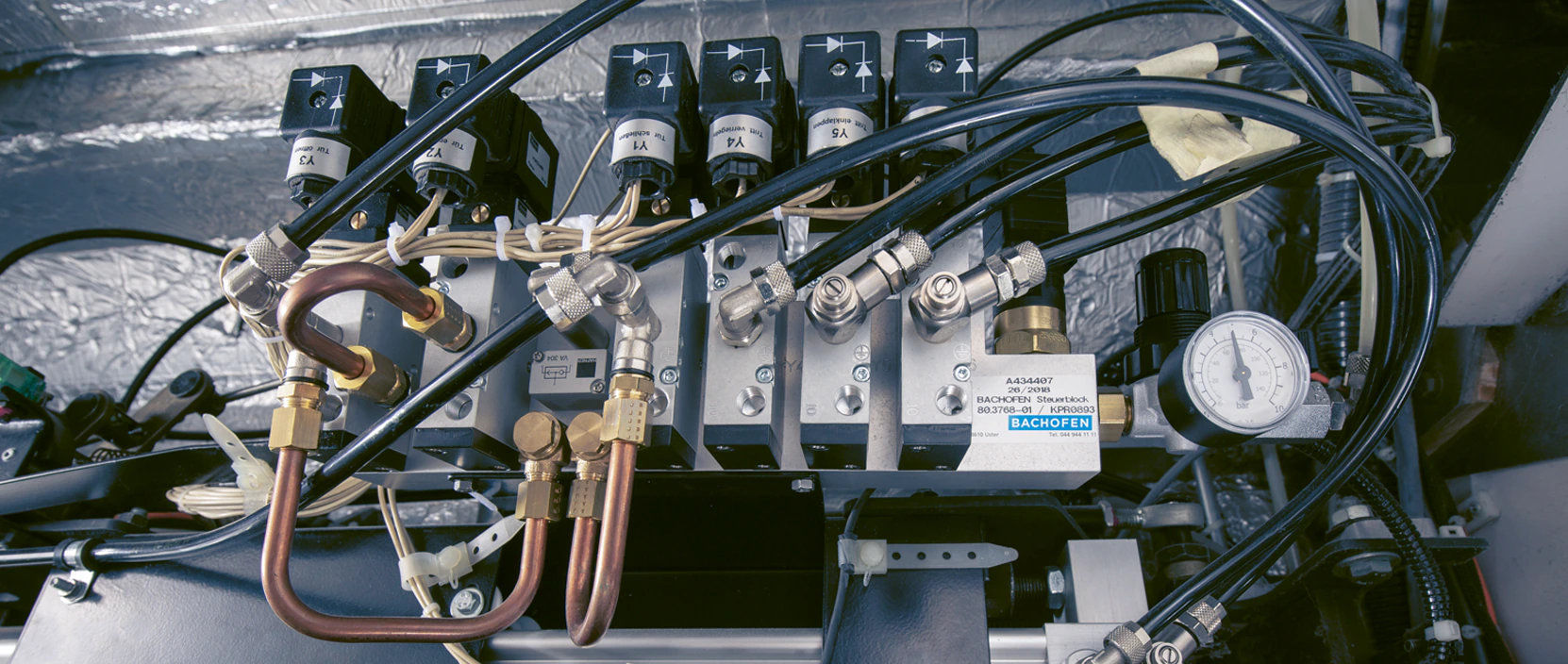

The responsible staff in the Operating division take particular care when procuring movable subsystems such as door and sliding step controls for passenger carriages. If the systems do not work properly, the train in question cannot be used. As a rule, it would not be an isolated case: «In a fleet of vehicles,» says Raphael von Arx, «such problems tend to occur repeatedly.» He has had unpleasant experiences with valve blocks in the door controls of some regional trains. The corresponding pneumatic systems used in older trains sometimes froze at sub-zero temperatures, so a suitable replacement had to be found.

Frost-resistant valve blocks with low maintenance requirements

Bachofen, a regular supplier to SBB for many years, took up this challenge and offered a solution based on valves from Parker, which won over the customer: Bachofen developed a concept that significantly simplifies the maintenance of the valves, and assembles the valve blocks according to customer specifications to create ready-to-install units. The new valve blocks have already undergone a wear test in harsh winter conditions. Raphael von Arx is confident about the results. For Bachofen, the project is an ideal opportunity to once again demonstrate its railway engineering know-how.