Riding clean with diesel exhaust: Stadler Rail vehicle manufacturer

Exhaust emissions from diesel engines are a burden on the environment. AdBlue systems are used to reduce emissions. In tight spaces such as in a diesel locomotive, installing such a system is a challenge. But Stadler’s got it under control.

Swiss rail vehicle manufacturer Stadler can look back on an impressive success story. What began in 1942 in an engineering office called Stadler in Zurich and continued 20 years later with the construction of their first factory building in Bussnang, Thurgau, is now a globally active company with an outstanding reputation: Stadler has established itself internationally as a seal of quality among rail operators.

Diesel regional trains for Sardinia

AdBlue for clean air

Adjustments to environmental legislation required the design and practical fitting of AdBlue systems in the final engineering phase of the trains. AdBlue is a urea solution that reduces the environmentally harmful nitrogen oxides contained in diesel exhaust by up to 90% and, like the diesel fuel itself, must be topped up regularly.

A complex design task

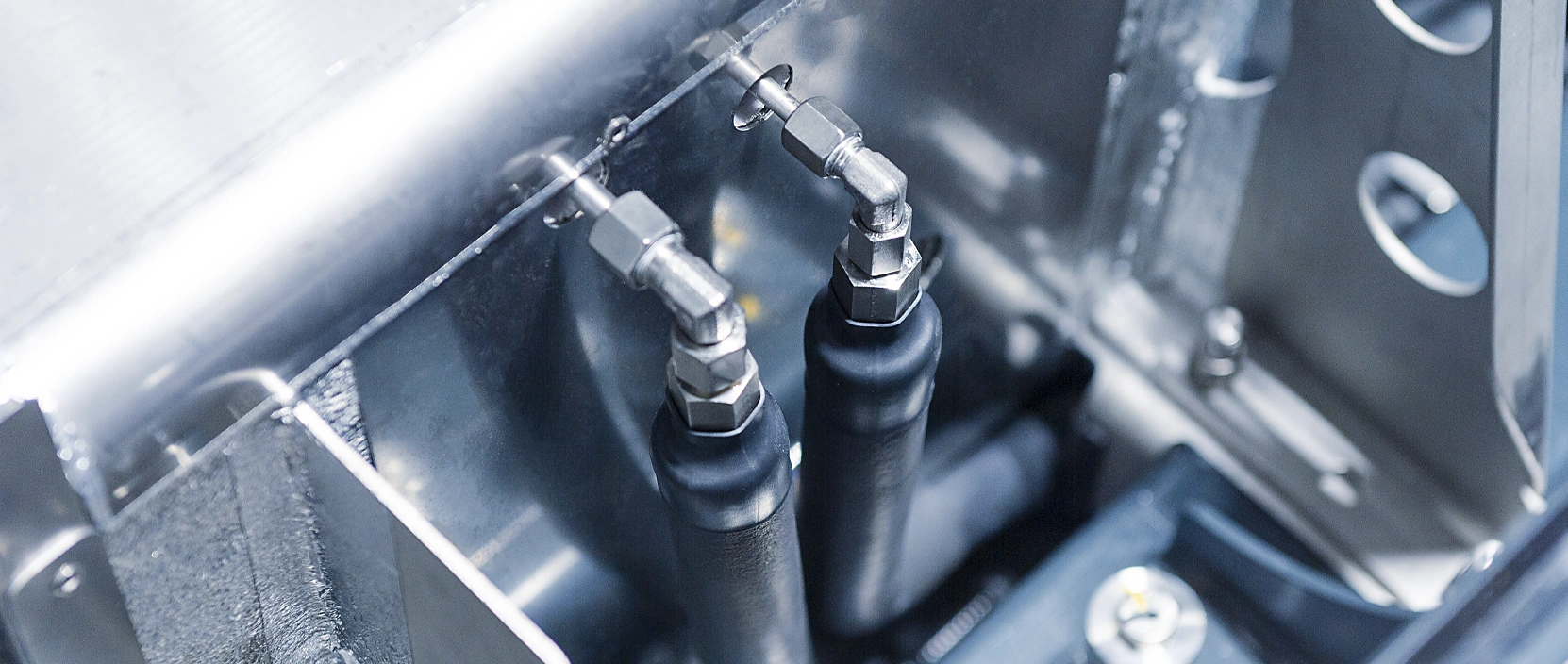

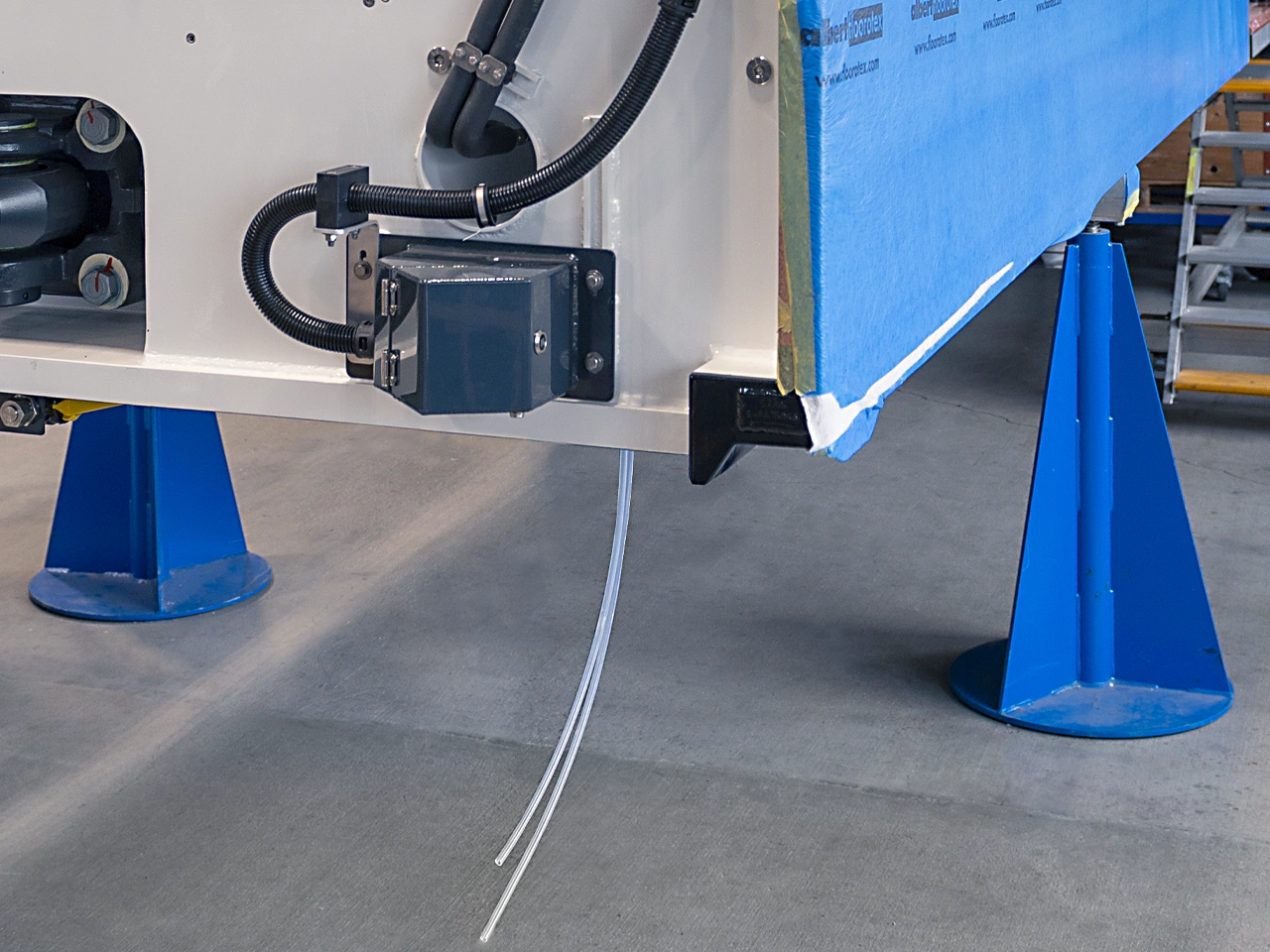

Stadler’s engineers were challenged to fit the AdBlue exhaust gas cleaning system into the already tight engine room. This required a system of lines from the filler tank in the lower part of the vehicle to an intermediate tank mounted at the other end of the vehicle above the engine. An injection unit connected to this supplies the chemical to the exhaust tract upstream of the SCR catalytic converter. To prevent overfilling, the line system had to be equipped with a recirculation system, thus doubling the routing of lines.