Estavayer lait SA dairy: a prime example of food safety

Hygiene is the top priority in the food and beverage industry. ELSA, a dairy belonging to the Migros Group, uses the most modern CIP systems to clean its plants. This means that there are particular demands placed on the valve technology.

Gottlieb Duttweiler, founder of the Migros chain of grocery stores, always had the welfare of consumers in mind. With his revolutionary idea of bridging the gap between producer and consumer, he made daily necessities affordable for everyone. A logical part of this was taking production into his own hands. It was on his initiative that the Estavayer Lait SA dairy, or ELSA for short, was founded in 1955. Today, the dairy produces a wide range of dairy products geared to modern consumer habits as well as alternatives based on vegetable proteins.

Sustainable production and the highest quality standards

The Migros founder was primarily concerned with quality at an affordable price. Today, sustainability in production and uncompromising product safety would undoubtedly also be among his main concerns. ELSA fulfils these requirements in an exemplary manner: in 2018, the company launched an initiative for a future-oriented dairy industry that takes animal welfare and environmental protection into account. Production at the Estavayer-le-Lac plant meets the highest hygiene and quality standards and is ISO 9001 and IFS Food certified.

Ambitious requirements for valve technology

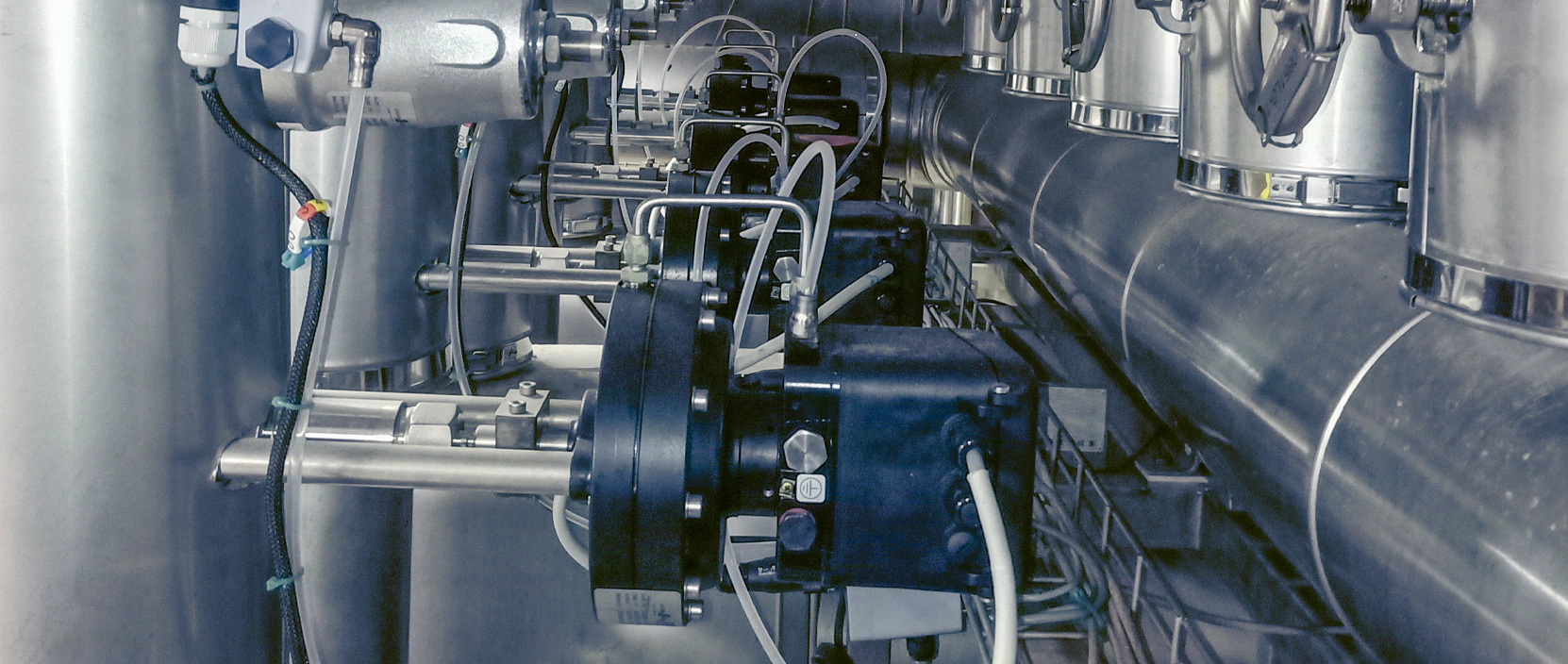

As part of a drive to modernise production, ELSA planned to install a new CIP (cleaning in place) system. For the associated steam heating system, an invitation to tender was issued for the valve technology, which had to be able to cope with the special properties of steam as a medium. ELSA shortlisted three suppliers. Expectations were high: in addition to conventional requirements such as process reliability, ease of maintenance and exact control quality, the decision would also be based on the important criteria of reliability and a long valve service life. The target was an operating life of 100,000 hours.

Bachofen’s industry-specific consulting expertise

Bachofen emerged as the winner of the tender. ELSA opted for the sliding gate valves from Schubert & Salzer, which are used successfully worldwide in the food and beverage industry. The product’s light weight, precision and freedom from maintenance – a particularly important criterion in the decision due to the installation height of three metres – spoke in its favour. For Nicolas Roulin, who is responsible for procurement and system maintenance at ELSA, Bachofen’s industry know-how and professional support were also decisive: «Bachofen knows the processes in the food and beverage industry and, in particular, also has the necessary expertise when it comes to dealing with the medium of steam. For example, Bachofen ensured the correct dimensioning of the valves.»

ELSA is extremely satisfied with the outcome of the procurement project. The interplay of a first-class product with value-adding consultancy services has contributed to a thoroughly clean solution that will last for the next ten to twelve years.