Home > Machine tools > Manpower: too good for repetition and routine

Manpower too good for repetition and routine

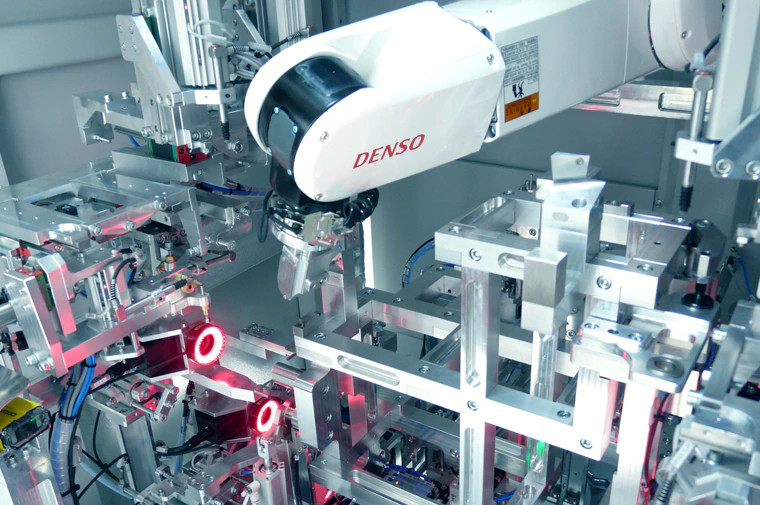

High-performance machine guarantee a high level of productivity thanks to efficient production. This is compromised if an operating person is required to load and unload the machine. DENSO robots handle this routine work in a reliable manner and without delays, leaving employees free to carry out skilled work.

Automation can offer significant benefits if it is used consistently. Modern machine are theoretically able to carry out production 24 hours a day, seven days a week, 365 days a year, largely independently of the human workforce. If operating personnel need to be present to load and unload the machine, the automation potential is not being fully exhausted. This situation is regarded as unsatisfactory, as this work is ideally suited for robots. Robots remain permanently operational, save on shift work, do not generate wage or social costs and do not suffer accidents in the workplace.

4 and 6-axis robots with IP67 certification

Together with the technology partner DENSO, Bachofen offers a wide range of 4 and 6-axis robots that carry out loading and unloading of machine and increase the level of automation involved in the manufacturing process. As DENSO robots are certified for protection class IP67, they are particularly suitable for industrial applications in a harsh working environment. Dust and splashes of water cannot prevent them from carrying out their tasks in a safe and reliable manner.

Easily integration in machines

Easily integration in machinesIn the case of long loading and unloading procedures, DENSO robots can be assembled on an external axis that can be controlled using the robot controller. Thanks to their compact design, they are also suitable for integration in machine and can act as flexible helpers, carrying out a number of different functions. The IP67 protection is also a benefit in these applications.

Versatile communication talent

DENSO robots are able to communicate. They have digital inputs and outputs but also communicate via a fieldbus (for example Profibus) or via ethernet such as EtherCAT. The internal cable and pneumatic hoses and the integrated valves make it considerably easier to control the gripper.

As an automation specialist, Bachofen helps you eradicate the weak points in your manual process for loading and unloading machine and helps you develop fully automated solutions for your customers, with expert advice and the right robot for any application.

Discover more products from DENSO

Typical areas of application

-

Loading and unloading machine

-

Flexible integration in machines or machine groups

-

Completion of palletisation tasks

Greater production efficiency in a fully automated manner

-

Protection class IP67

-

No safety fencing required thanks to «Safety Motion»

-

Extremely compact design

-

Wide range of products for various scopes

-

Two additional axis connections