Plant construction and engineering from SPE Tech – what else?

As a company specialising in sustainable process and energy plants, SPE Tech AG focuses on customer proximity, flexibility and customer-specific solutions. These qualities also won over the producer of the most famous capsule in the world.

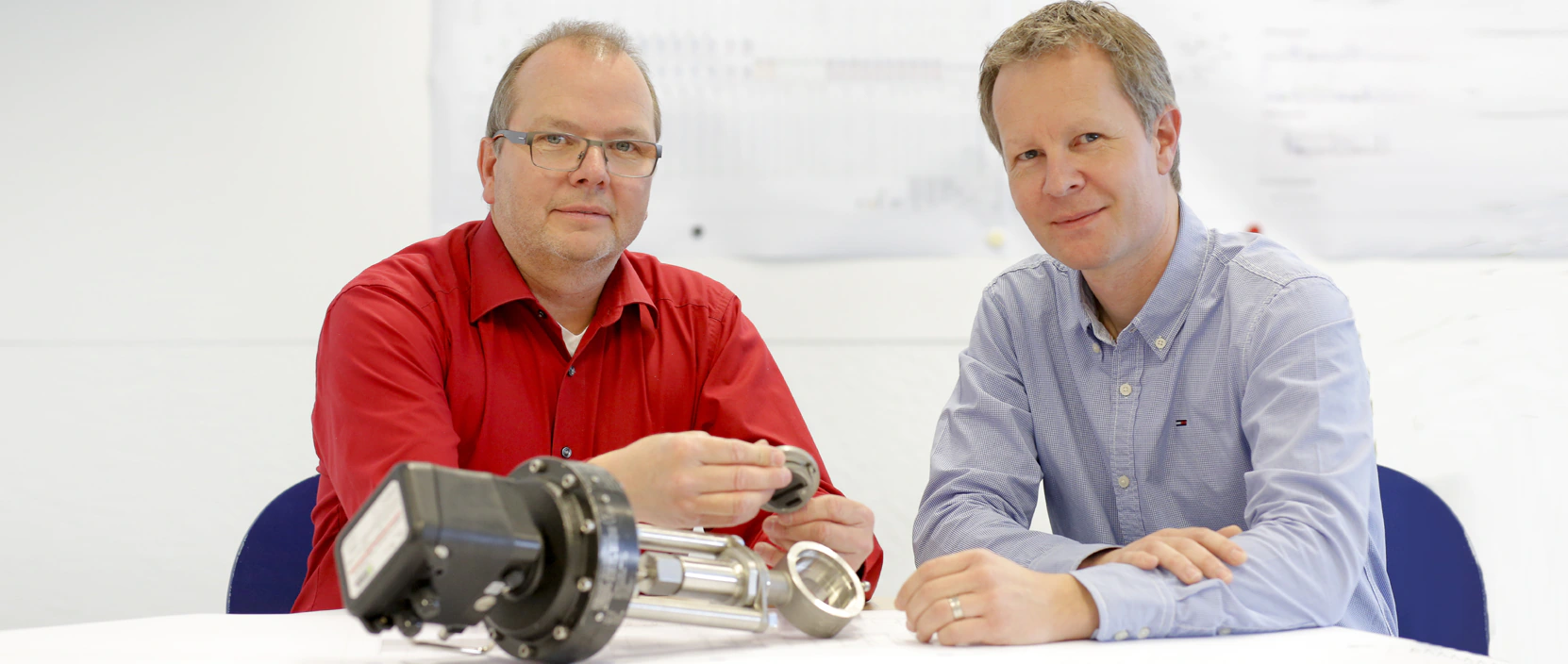

The SPE Tech AG management team is modest. They are actually newcomers to the market and are still little known in industry circles. But this self-assessment is deceiving. Since it was founded in 2008, the planning and engineering company has grown continuously and quadrupled its workforce.

Success is no accident. SPE Tech’s engineers, technicians, process designers and project managers have extensive knowledge of operational and plant planning as well as many years of experience and specific industry knowledge. This knowledge is particularly evident when it comes to the production of foodstuffs and pharmaceuticals.

Interdisciplinary internal cooperation as a success factor

SPE Tech specialises in the planning/engineering and construction of plants in the areas of process technology, energy supply and media. In process technology, the focus is on the development and implementation of process engineering solutions. When it comes to energy, their key competences are coordinating energy generation and production processes, exploiting savings potential through process optimisation and increasing energy efficiency with intelligent concepts for heat recovery.

By linking process and energy technology, SPE Tech achieves synergies that create added value for customers and have a direct impact on productivity. The company’s engineers and technicians work together on an interdisciplinary basis, exchanging knowledge and experience and developing solutions that are precisely tailored to customer needs.

Engineering for the Nespresso plants in Avenches and Romont

Alongside numerous other renowned companies such as Migros and Coop, Nestlé Nespresso SA also makes use of SPE Tech’s interdisciplinary expertise, flexibility and in-depth process know-how. The manufacturer of the world-famous and now legendary coffee capsules commissioned SPE Tech with extensive engineering tasks in the course of the construction of new production facilities for the Nespresso plants in Avenches and Romont.

To produce the highest quality coffee, highly sophisticated valve technology is required along with other elements. The SPE Tech engineers opted for valves from the quality brand Schubert & Salzer, provided by Bachofen. Thanks to their reliability and durability, these products guarantee a trouble-free and safe production process.

Valve technology from Bachofen for coffee production

Several hundred seat and sliding gate valves from Schubert & Salzer are already in use in the Nespresso plants. These are special designs made of materials that are suitable and approved for the food industry. As part of a pilot project, the suitability of further valves from the Bachofen range for use in heat recovery plants is currently being tested.

However, SPE Tech did not decide to work with Bachofen solely on the basis of product quality. Rudolf Lauper, Managing Director: «We prefer to work with suppliers who share our philosophy of customer proximity. This includes openness, fast response times and technical support. Bachofen is one of the partners who meet this expectation.»