Not a drop too much, not a drop too little: FMQ flowmeter from Anderson-Negele

Poor control of flow in production equipment pipelines will affect process efficiency and incur costs. The more accurate the measurement, the safer the production process. The FMQ flowmeter from Anderson-Negele shows what is happening in the pipe with maximum precision.

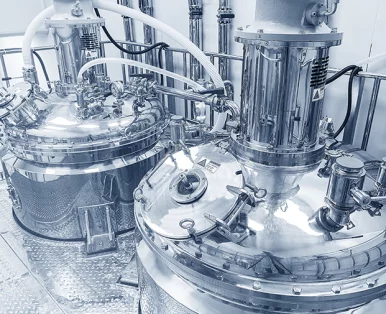

Product losses due to inaccurate filling, deviations in dosage or insufficiently precisely defined fluid volumes when filling and emptying tanks are disruptive factors that are costly in the long-term and ultimately have a negative impact on product quality. The safety of processes is paramount for companies in the food and pharmaceutical industries in order to meet the requirements of the regulators and to survive in the market. Precise measurements of the processes in the production plants are therefore vital.

Compact and extremely reliable all-rounder

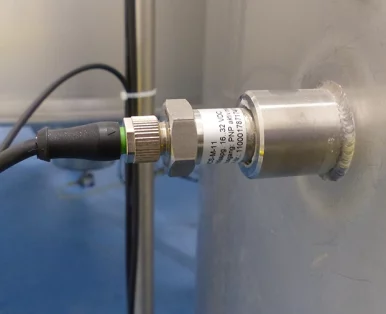

The magnetic-inductive FMQ flowmeter and flow monitor from Bachofen technology partner Anderson-Negele gives designers and operators of systems a compact precision device that is suitable for a universal range of applications. Thanks to the fully encapsulated magnetic field coils, the component is resistant to vibrations and works perfectly in wet environments. The robust concept of the device is based on it being made of stainless steel and having a vacuum-resistant measuring tube lining made of high-quality PFA.

High measurement accuracy and IO-Link

The flowmeter is designed for a constant process temperature of up to 100°C, but can withstand temperatures up to 130°C for a maximum of 30 minutes during CIP/SIP cleaning processes. Its measuring accuracy of ±0.5% ±2 mm/s also makes the device suitable for low flow volumes. The flowmeter can communicate using either a 4-20 mA signal, a pulse output or IO-Link. It can be configured using the display on the device or the IO-Link interface. The device parameters can be saved to a higher-level system using the same interfaces.

Virtually unlimited connectivity

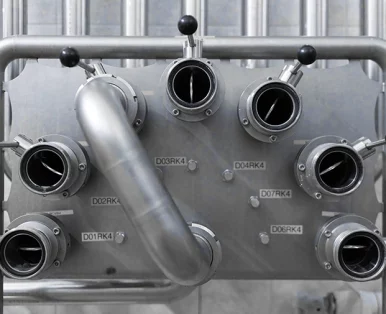

Measuring tube sizes from DN10 to DN100 enable applications from 30 l/h to 300,000 l/h for the flowmeter from Anderson-Negele Virtually no limits on connectivity either: Bachofen can supply all common process connections such as milk pipe thread to DIN11851, aseptic screw connection to DIN11864, TriClamp and many more. At Bachofen, however, users will not only find the right solution, but also competent partners to support them with technical advice.

Discover more flowmeters

Areas of application

- Milk processing industry

- Breweries

- Food industry

- Pharmaceuticals industry

Measurably impressive

- Durable, compact product design

- Output 4-20mA, pulse and IO-Link

- Vacuum-resistant PFA measuring tube

- CIP/SIP-capable

- Compliant versions for the food and pharmaceutical industries