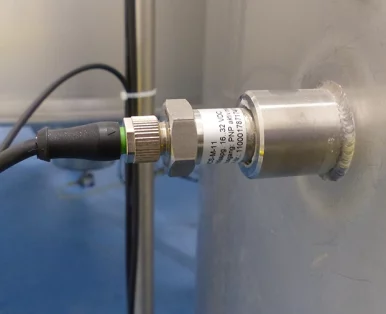

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes critical for the machine and triggers an alarm, for example via IO-Link.

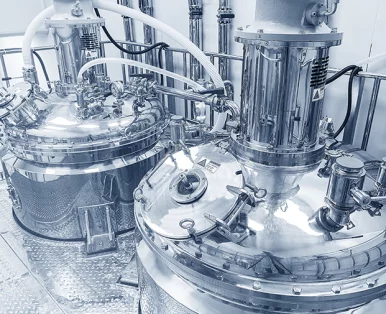

Vibrations are a normal side effect of rotating machines. Even when new, they are not immune to fine vibrations. Malfunctions and failures may occur if the intensity of the vibrations exceeds the specified tolerances. Causes of a critical increase include imbalance, loosening machine parts, misalignment of shafts or dirty rotor blades. An increase in vibration may also be an indicator of damaged or worn tools.

ISO 10816-3 as a guideline

The ISO 10816-3 standard provides precise limits for the effective vibration speed of rotary machines. It determines whether the vibrations are still in the new machine range, whether maintenance is required or whether the vibrations are so strong that they may cause serious machine damage. Theoretical reference and limit values are one thing. Constant measurements on the machine are quite another. In addition to vibration, they include controlling the operating temperature which can reach an unhealthy level due to the effects of friction.

Identify potential faults and prevent machine damage

Bachofen technology partner Turck has developed a solution that kills two birds with one stone in the form of the CMVT-QR20 vibration and temperature sensor with IO-Link. The multi-functional device continuously detects the vibrations and temperature of the machine and indicates when intervention is required. The plant operator detects any impending faults promptly and can remedy them before costly damage and unplanned machine downtimes occur. Productivity is maintained without unnecessary interruptions.

Freely parameterisable threshold values

The CMVT-QR20 vibration and temperature sensor from Turck detects the smallest changes in vibration behaviour. It transmits the corresponding process value to the controller for analysis via IO-Link and/or SIO. The alarm and warning limits can be freely parameterised and can be tailored to the application. The IO-Link protocol guarantees simple data transfer and generates additional information, for example for sensor identification or operating hours.

The CMVT-QR20 vibration and temperature sensor from Turck increases the reliability and the service life of your machine. At Bachofen, this precision component is now available with a short lead time.

Buy Vibration & Temperature Sensor in Shop

Discover more products from Turck

Areas of application

- Pumps

- Electric motors

- Compressors

- Engines

Complete peace of mind

- Maintenance-free

- IP68/IP69K with high shock resistance of 200 g

- Temperature range from -40°C to +85°C

- Free web vibration monitor via IO-Link master