Home > Automation technology > Visionary capabilities: predictive maintenance from Banner

Visionary capabilities: predictive maintenance from Banner

Once machines start to vibrate, production can stall or come to a complete standstill and the costs resulting from downtime can take on astronomical proportions. Predictive maintenance using a solution from Banner will ensure that things can never get that far. The reason for this is that the system is self-learning and can identify faults, before they occur.

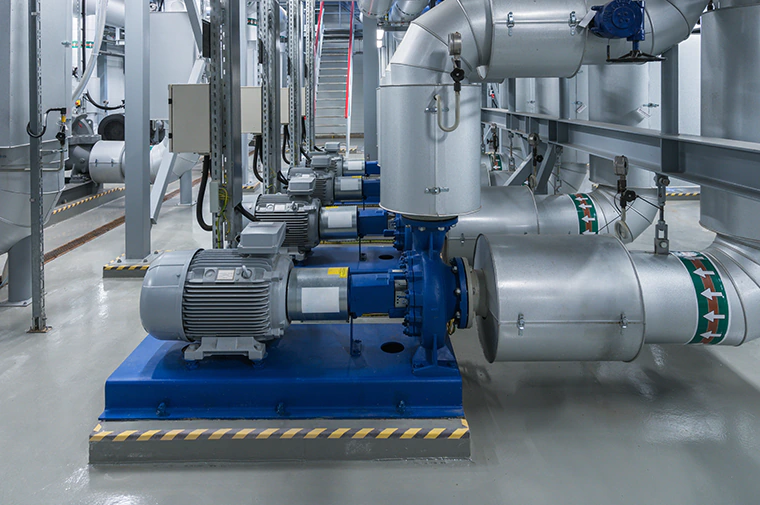

Excessive vibrations caused by defective bearings, such as special bearings or cross roller bearings, affect the operation of motors, drive systems or ventilation systems and, in the worst-case scenario, can cause massive damage. In order to ensure safe operation, temperature and vibrations need to be permanently monitored. Predictive Maintenance and Condition Monitoring, the smart monitoring system from Banner, is used for that precise purpose. Preventative maintenance prevents plant downtime and enables maintenance work to be scheduled in a targeted way.

Machine learning for preventative system protection

The predictive maintenance solution from Banner makes use of sensors to record vibrations and temperature changes in rotating parts within your plant and delivers the data via wireless networks. This means that you will be able to view the current functional capability status of your machinery at all times. The benefits of Banner’s system are not limited to monitoring alone. It is actually self-learning. It continually reads the data regarding the current status of the part of the plant being monitored; it automatically defines the conditions and sets threshold values for the transmission of warning and alert messages. You will therefore know in advance and with certainty at what point in time the next maintenance intervention needs to be carried out on the part of the machine concerned. Automated monitoring that incorporates a machine-learning component makes manual calculations a thing of the past and prevents operations being interrupted due to incorrect data inputs.

Ready to operate in just a short time and without any need for programming

Incorporating a predictive maintenance solution and installing the vibration and temperature sensors in your plant are extremely simple tasks and do not require any specific construction changes. Programming is also not required: In just a few simple steps, you can connect the monitoring box and link the nodes using a touch screen. You then need to install the sensors and data capture can begin.

For proactive plant constructors, Bachofen is the right company to contact in connection with predictive maintenance using the Wireless Vibration and Temperature Monitoring Solution Kit from Banner. After all, competent advice and technical support will help you ensure a future-proof solution.

Downloads

You can find the Banner Solution Vibration in the online shop

Discover more products from Banner

Areas of application

-

Monitoring the vibration and temperature of rotating plant components

-

Monitoring of pumping stations

-

Monitoring motors, drive systems and critical ventilators for production

-

Predictive maintenance

No mor vibration in your plant operations

-

Significantly reduces the risk of production downtimes

-

Wireless data transfer for ease of implementation

-

Ongoing updating of status thanks to machine learning

-

Ability to connect up to 40 sensors per cabinet

Other focus topics in the area of factory automation and infrastructure

Visionary capabilities: predictive maintenance from Banner

Once machines start to vibrate, production can stall or come to a complete standstill and the costs resulting from downtime can take on astronomical proportions. Predictive maintenance using a...

Tanks under control: reliable cut-out technology

When a blackwater tank has reached the maximum fill level in the sewage system of a machine or in the toilet of a train carriage and the detection system...

Shining a light on assembly processes: the pick-to-light solution from Banner

Making mistakes is human. Even the most reliable employee can make mistakes during commissioning and those mistakes can cause the installation process to stall, affecting productivity. Using a Pick-to-Light...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

Moving securely ahead into the future of cloud computing: data transfer using the edge gateway from Turck

Industry 4.0 is entirely dominated by the cloud, however the massive potential offered by these types of technology is still far from being exhausted. The key when it comes...

IIoT and industrie 4.0: Ewon Flexy gets you close to the action

A genuine nightmare for plant operators – a fault affects operations and, in the worst-case scenario, brings production to a standstill. You do whatever you can to rectify the...

Hot and cold in alternation: a heat exchanger’s job

The principle of temperature transfer from one medium to another without direct contact between the media is used in an extremely diverse range of industrial processes. As such, the...

Getting ahead in the world of RFID: the new UHF RFID read/write head from Turck

RFID-based applications used in materials handling and in goods logistics are many and various. Until now, it was a case of using the right reader for the right application,...

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes...

Now remotely controlled by IO-Link: Positioner 8049 from Schubert & Salzer

In plant operation, personnel deployments on site may be time-consuming and awkward in some situations. This also applies to adjusting and maintaining control valves, which are often difficult to...

Modular alarm design in variations: K100 Pro Beacon hazard indicator from Banner

It is in the nature of industrial production that it is associated with safety risks. Where hazardous substances are involved in production and processing plants, potential risks cannot be...

Don’t get pool water in your drinking water: Double-walled plate heat exchangers from Alfa Laval

In indoor and outdoor swimming pools, heat recovery from the drain water is the order of the day in terms of energy. But it also has its pitfalls. Double-walled...

Efficient use of space and energy: Sliding gate valve from Schubert & Salzer

Space and energy usage is becoming increasingly important when planning production plants. Space is a precious commodity and wherever energy can be saved, the opportunity should be taken. One...

So users aren’t left out in the rain: Moisture sensors from Liebherr

The moisture content of bulk materials is measured for more than just quality assurance. It is also relevant to the energy efficiency of processing operations. With the precise humidity...

Automation? Yes, of course!

The increasing automation of industrial processes demands reliable safeguarding of the hazardous areas surrounding machines, robots, transfer lines and automated guided vehicle systems. The safety requirements specified in the...