Home > Uncategorized > Discrete bandwidth: Turck excom Ethernet IO system – fit for IIOT

Discrete bandwidth: Turck excom Ethernet IO system - fit for IIOT

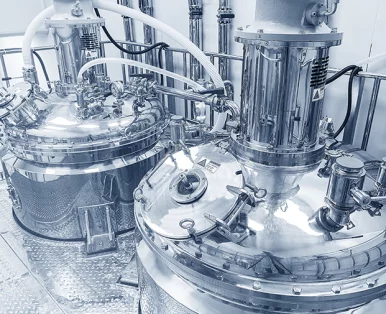

Bottlenecks in data transmission using classic fieldbus systems restrict the use of the data. The available bandwidth is not sufficient to transfer the additional data from today’s sensors in full. Turck is now launching new Ethernet gateways for the excom IO system, which make process communication IIOT-capable and thus significantly increase bandwidth.

It is rare, but it does happen – an automation component gives up the ghost. This means that parts of the plant must be shut down to resolve the problem. This is all the more annoying because process data indicates defects and therefore enables predictive maintenance. Or at least it does in theory. In practice, the problem is often a lack of bandwidth. Because the bandwidth of fieldbuses is limited, a large number of metadata generated and transmitted by HART, Profibus-PA or FOUNDATION fieldbus field devices is only used sporadically during device replacement or calibration.

New perspectives thanks to NAMUR Open Architecture

The NAMUR Automation Technology Interests Group of the process industry has responded to the problem with a smart idea: Their innovative concept of the NAMUR Open Architecture (NOA) envisages the establishment of an additional data channel parallel to the automation pyramid. The connections between field devices and between I/O and the control system level are left untouched. The data is transferred through the parallel connection and can be analysed independently of the fieldbus.

Revolutionary process communication with Turck

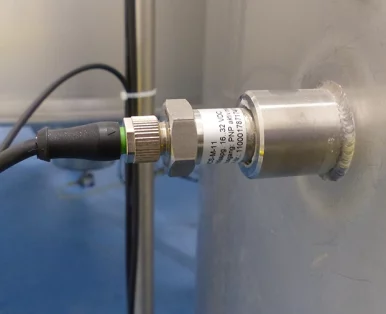

The automation specialist and Bachofen technology partner Turck has taken up the ball and taken a huge step forward in the bandwidth issue with the new Ethernet gateways for the excom IO system. The process and diagnostic data as well as other information are continuously transferred to the control system via IIOT – either on premises to local servers, to the Turck cloud or to other cloud solutions preferred by the plant operator. Data security is ensured by the simultaneous data access without write rights and the highest level of encryption.

Configurations for dedicated environments during operation

Progress in automation technologies does not stop even before being used in potentially explosive atmospheres or in plants running at full capacity. Thanks to HCiR (Hot Configuration in Run), the IIOT functions for the excom Ethernet I/O system enable device replacement, system expansion or maintenance during operation even in these critical applications.

Automation cracks

Whether it is the development of a new automation environment or upgrading an existing plant – discuss your project with Bachofen automation specialists. To make the implementation of the IIOT functions in your process communication a success.

Buy remote I/O system excom in the shop

Discover more products from Turck

Areas of application

- Pharmaceuticals industry

- Chemical industry

- Process automation

Free path in the data channel

- Web server for easy configuration and handling

- Simple interconnection of different plant modules through Module Type Package (MTP)

- Direct access to HART field devices

- Facilitated modularisation of systems through multi-protocol properties of the excom system