Maximum precision in miniature measuring ranges: Inductive sensors with IO-Link from Turck

Measurements in micro dimensions can be too much for conventional sensors to handle. The range of measuring sensors available on the market is extremely small, especially in cases where the highest level of precision is required. However, Turck is answering the call with an innovative solution: A new range of measuring inductive sensors with IO-Link and analogue output.

Whenever it’s necessary to measure gap dimensions, metal part wear and other parameters in the micro range, most measuring sensors based on the optical principle quickly reach their limits. Although they are accurate, they are also more expensive and prone to contamination. The high temperature fluctuations that occur in numerous production environments pose an additional problem: A measuring sensor must also be able to take these circumstances into account.

High measuring accuracy with diagnostic data as an added bonus

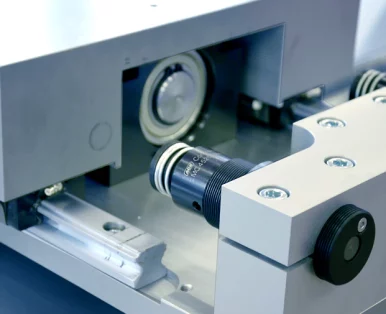

Bachofen’s technology partner Turck has conjured up another product line for the market: A range of measuring inductive sensors with IO-Link and analogue output that can carry out small distance measurements with maximum precision and, thanks to their robust design, remain unaffected by aggressive environmental influences. The IO-Link interface marks a further step into the future of automation: In addition to the actual measurement, the sensors output a whole range of diagnostic data, such as the internal temperature or the number of cycles, making them a pioneering example for condition monitoring and predictive maintenance.

Unique thanks to comprehensive functionality

The sensor range includes flush-measuring types as well as three non-flush-measuring versions. Within a range of 12 mm, users can choose between the output of a distance-proportional signal as an IO-Link process value and a voltage signal of 0 to 10 V. As the measuring range can be adjusted flexibly, the complete signal range is also available for small measuring distances. Other functions that underline the unique nature of the Turck sensors include the compensation of temperature fluctuations and a perfectly linearised output signal.

Versatile application possibilities

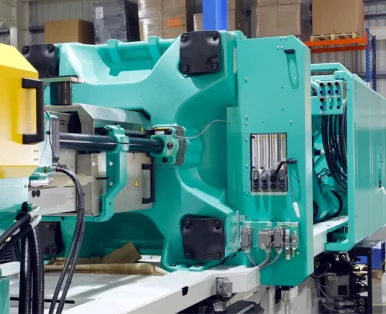

The range of applications of the measuring sensors with IO-Link from Turck extends from monitoring the gap dimensions on industrial rollers to detecting wear on moving parts, as well as use as a low-cost rotary encoder or linear position sensor. They can also output linear and rotary movements in the form of analogue position signals — for example, for inclined planes or eccentric screws.

No matter which application Turck’s measuring inductive sensors are suitable for, the technical advice based on Bachofen’s comprehensive automation expertise guarantees a suitable solution.

Discover more products from Turck

Areas of application

- Simple distance measurement

- Monitoring of mechanical play

- Wear detection

- Concentricity monitoring of shafts

A highly capable all-rounder

- Maximum precision thanks to linearity deviation of <1%

- Temperature compensation

- IP67 and temperature resistance from -25 to +70°C.

- IO-Link and analogue output