Home > Automation technology > Lights that speak: the new WLS27 pro-lights from Banner

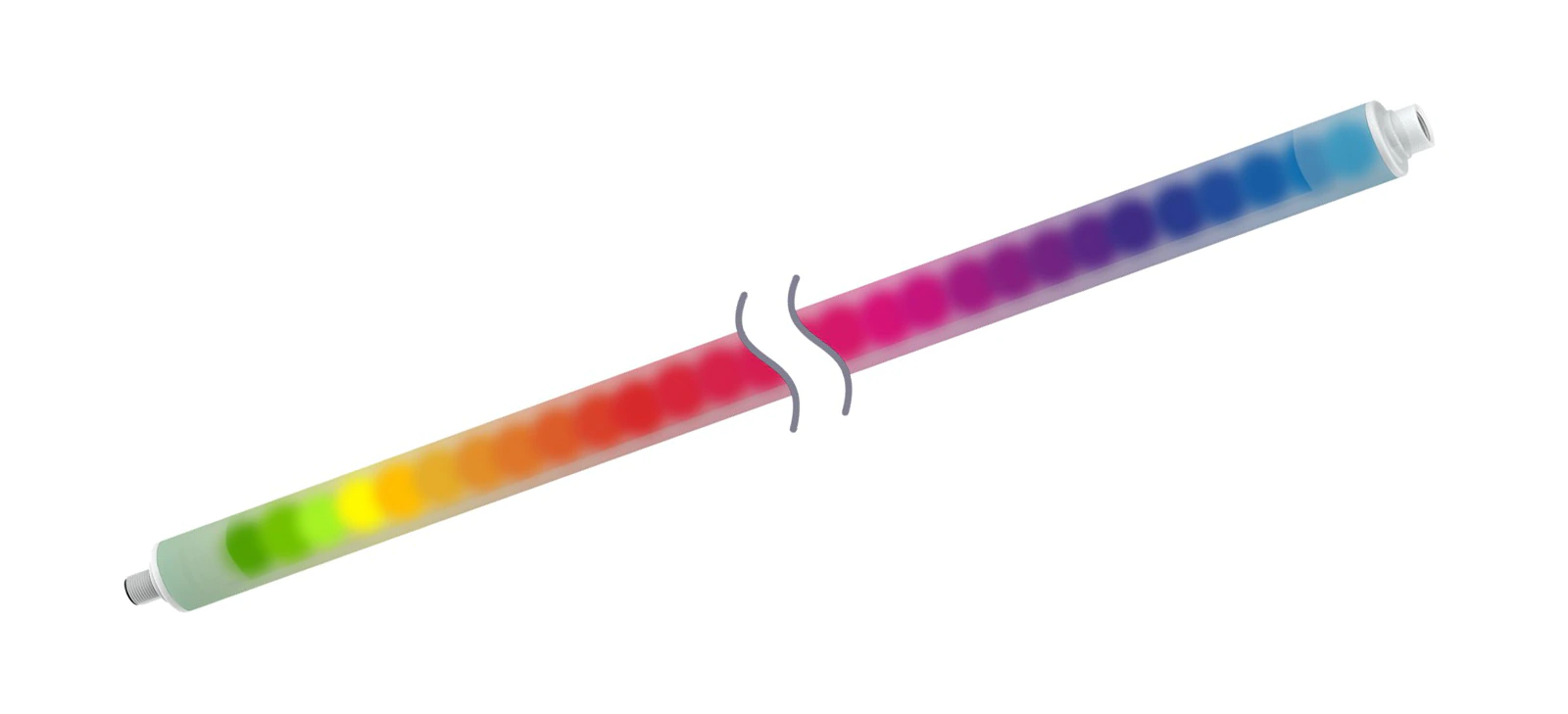

Lights that speak: the new WLS27 Pro-lights from Banner

When monitoring machinery, processes, actions or user behaviour, speed and clarity are paramount. The most efficient medium for these purposes is light. With its new WLS27 Pro-lights that are programmable using IO-Link, Banner has considerably expanded the range of possible applications.

In industrial manufacturing contexts and work processes, the rapid transmission of operational information and warning signals is of key importance. A decisive factor, however, is whether the signals are noticed and understood. If, for example, the fill-level of a tank is about to reach its upper limit, immediate action needs to be taken. If delivered in time or in advance, status notifications for machinery or plants can help prevent downtime. Displaying the distance to an obstacle also prevents collisions. These are just two examples of a long list of cases that lend themselves to the deployment of smart lighting systems from Banner, as a safe, reliable and flexible solution.

Multifunctionality, thanks to IO-Link

LED strip lights from the WLS27 range incorporating two, three or even five colours are proving their worth worldwide in an extremely large number of industrial production applications. Even in harsh environments, such as automatic car washes, they operate without a hitch. Banner has now expanded this successful range and is launching its new WLS27 Pro series. These innovative lights can be deployed as lighting, display or information components. For applications in which limited space is available, they form the ideal solution when it comes to conveying data and instructions to the user of a machine in real time. They also constitute a shining example of multifunctionality, as they can also be programmed and controlled via IO-Link.

Ten segments that can be programmed individually

The products in the new WLS27 Pro series consist of ten segments. For each segment, the intensity, colour selection and animation can be set individually. When it comes to conveying information, this in itself provides a wealth of possibilities that can be used in an application-specific way. The latest generation of smart lights from Banner provide certainty – whether this relates to the precise position of moveable objects, measuring distances or recording the number of items or execution times. In production processes, they can be used to display the parts passing by on a conveyor belt, or as a timer displaying the amount of working time remaining before the operator is able to extract a part from the machine.

A broad spectrum of colours and a variety of lengths

The animations in the IO-Link controlled lights are created using a laser sensor that converts analogue values into digital signals and transmits these using frequency or pulse-width modulation (PWM). The colour palette includes degrees of whiteness, from Warm White (2700 K) to Cool White (6500 K), together with thirteen additional colours. The components can be supplied in six different lengths from 145 mm to 1130 mm, either in standard diffusion glass or high-diffusion glass.

If what you need is comprehensive advice, the clever people at Bachofen will be happy to help. They will shed light on the wealth of possible applications of the new WLS27 series from Banner and will use their technical expertise to help you reach a decision.

Discover more products from Banner

Areas of application

-

Lighting and information management at workstations

-

Visualising distances, fill-levels or time remaining

-

Indicating the status of the work area available in robot cells

-

Guiding operating staff through the assembly and production processes

Glowing prospects

-

An IP69K rating for use in harsh environments

-

Functions are subdivided into ten freely-programmable segments

-

Variable intensity and a free choice of colour for each segment

Other focus topics in the area of equipment, machines, installations and machine tools

Lights that speak: the new WLS27 pro-lights from Banner

When monitoring machinery, processes, actions or user behaviour, speed and clarity are paramount. The most efficient medium for these purposes is light. With its new WLS27 Pro-lights that are...

Wireless vehicle identification: miniature guardians

Installing sensors for vehicle identification doesn’t have to mean digging trenches and laying cabling. Banner’s wireless alarms are smaller than a hockey puck, can be sunk into the floor...

Visionary capabilities: predictive maintenance from Banner

Once machines start to vibrate, production can stall or come to a complete standstill and the costs resulting from downtime can take on astronomical proportions. Predictive maintenance using a...

Out into the field: CODESYS-3 controller TBEN-Lx-PLC from Turck

Some machine manufacturers are still hesitant when it comes to relocating controllers into the field, even though the benefits of decentralization are very clear. The CODESYS-3 controller TBEN-Lx-PLC from...

Turck Ethernet Gateway for excom: make way for ethernet in the ex zone

The use of Ethernet in EX zones within the process industry was previously impossible due to safety issues. But now Turck has made a breakthrough with its GEN-3G Ethernet...

One IP address for an entire sub-network: all thanks to beep from Turck

With the TBEN-S, TBEN-L and FEN20 fieldbus modules, Turck is opening up new possibilities for machine and plant manufacturers. Each device on a network can be reached via an...

Tiny but mighty: the new HRG miniature roller guide from THK

A linear guide should take up minimal space but also deliver maximum performance. This contradiction inevitably leads to compromises when evaluating the options. But this is now a thing...

Solutions and expertise to meet your needs: Bachofen Engineering

As a rule, manufacturers come under a lot of pressure in terms of time, costs and innovations. And on top of that, they are faced with consistently high customer...

Shining a light on assembly processes: the pick-to-light solution from Banner

Making mistakes is human. Even the most reliable employee can make mistakes during commissioning and those mistakes can cause the installation process to stall, affecting productivity. Using a Pick-to-Light...

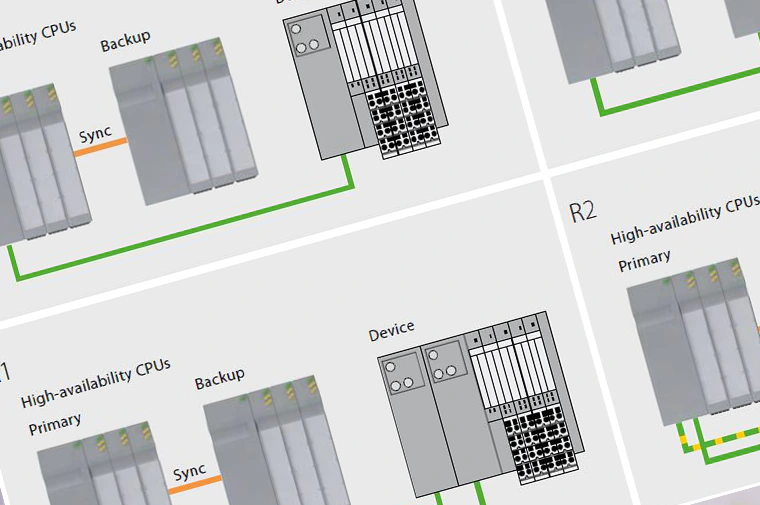

Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet has established itself as the communications standard for factory automation. Vehicle manufacturers and suppliers have been demonstrating the practical suitability of industrial Ethernet-based data exchange for a number...

Product identification: no cakewalk in the food industry

An identification system’s true value becomes most apparent when it is subjected to demanding general conditions. These are particularly challenging in the food industry. Due to its resistant properties,...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Procurement made easy: Bachofen safety technology from a single source

There are many aspects to the safety of machines, plant and vehicles. However, designers and operators have more important things to do than be setting up an evaluation process...

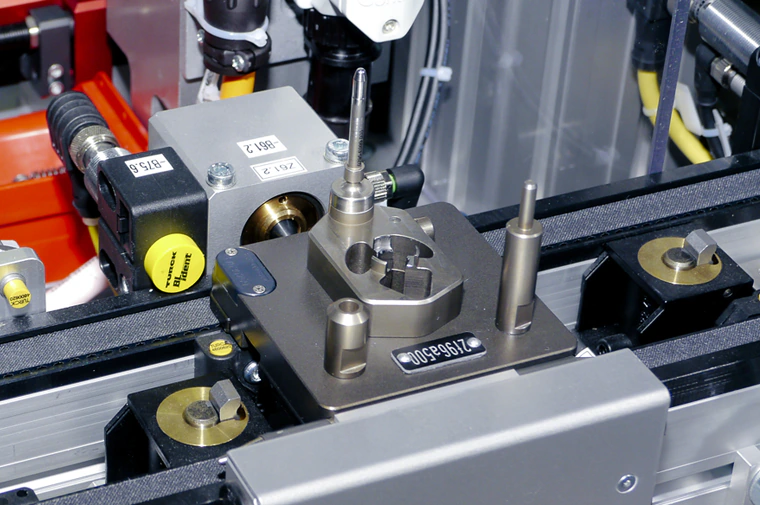

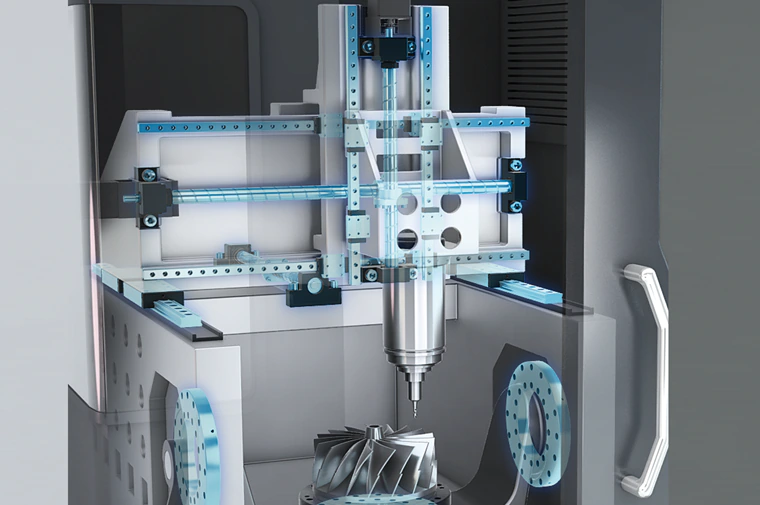

Prime example for industry 4.0: the machine thinks along with you

Is the tool suitable for the next processing step and when is the next service due? This information is crucial for ensuring that manufacturing runs smoothly with no long...

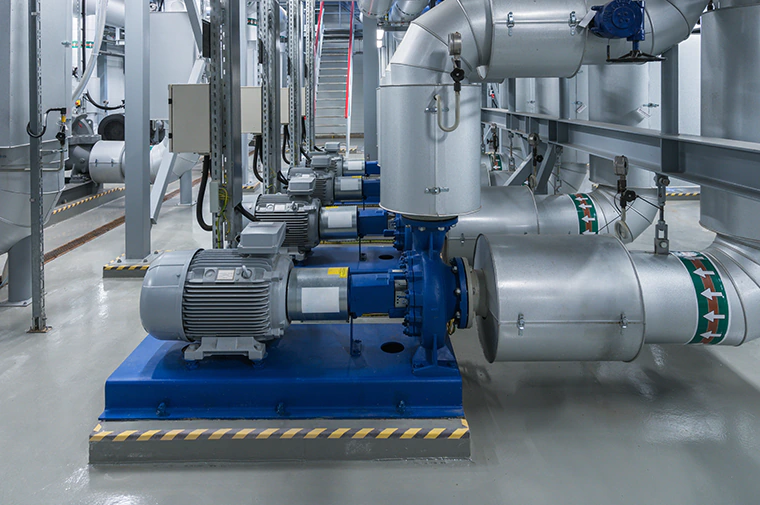

Prevention is better: monitoring using the Edge Gateway from Turck

Many operating faults in machinery and systems go undetected until the process itself starts to falter. If the operation was permanently monitored, any functional faults that were about to...

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Diversity and quality combined: Parker Rectus connection technology

Need to disconnect fluid connections quickly, cleanly and without any tools? Then look no further than the Rectus couplings from Parker. Parker has the right coupling for every conceivable...

Out of the control box: towards decentralised concepts

In the world of Industry 4.0, modularity is gaining increasing importance in the manufacture of machinery and systems. This development is also promoting the decentralisation of I/Os and control...

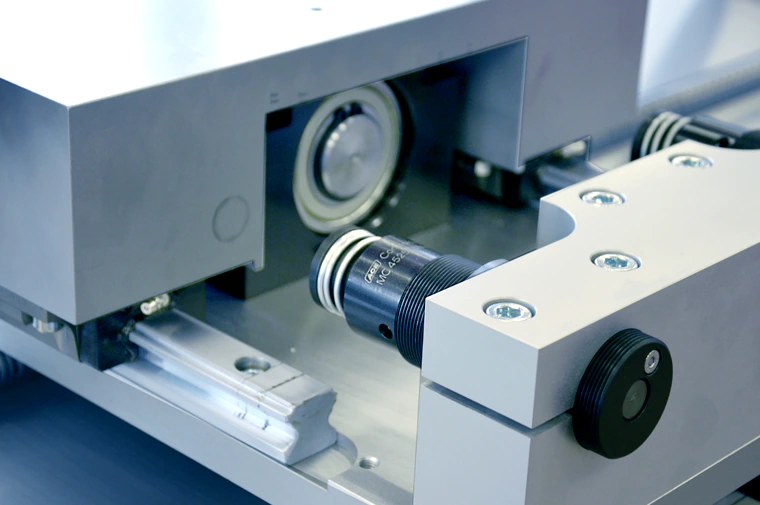

Optical sensor: green light for LED

Machine are carrying out increasingly complex functions and are increasingly networked, reflecting Industry 4.0. This also results in higher demands on the optical sensors. The future lies in LED...

On the move at high speed: the new BSM ball screw from THK

When speed is required, conventional ball screws quickly reach their limits. Traditional types have a DN value of between 60,000 and 120,000. THK’s new BSM ball screw exceeds these...

No risks in the control cabinet: the IM18-CCM control cabinet motor from Turck

Unplanned machine and system downtimes are a costly irritation for producers in the food, beverage and pharmaceutical industries. The cause can often be found in the control cabinet, which...

Eagle eyes in the compressed air network: flow sensors from EGE

Compressed air is expensive. One cubic meter can easily cost 10 to 20 Swiss centimes. Too much to waste. Flow sensors from EGE with IO Link display leakages immediately...

Moving securely ahead into the future of cloud computing: data transfer using the edge gateway from Turck

Industry 4.0 is entirely dominated by the cloud, however the massive potential offered by these types of technology is still far from being exhausted. The key when it comes...

Modbus-compatible and networked: electric actuators from Valpes

The ability of measurement and control systems to communicate is of central importance to the safe operation of systems. Electric actuators from Valpes can be configured and controlled using...

Manpower: too good for repetition and routine

High-performance machine guarantee a high level of productivity thanks to efficient production. This is compromised if an operating person is required to load and unload the machine. DENSO robots...

Linking factory and building automation: Intesis gateways from HMS Networks

There used to be a deep divide between information technology and operation technology. This was also a problem for building services, where automation is progressing in leaps and bounds....

Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the...

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as...

Interference-free wireless: say goodbye to interference

Wireless networking is a key element of Industry 4.0. It is, however, difficult to implement in industrial environments. Until now, interference and long distances have affected the wireless transfer...

Distance yourself from mediocrity: the Turck uprox® 3 factor 1 sensors

Inductive sensors, for applications in special machine engineering and other demanding fields, should ideally have high switching distances, be compact and form a key element for reliable machine and...