Home > Uncategorized > Press it in and it’s ready to go: The new LMHB ball bushing from THK

Press it in and it's ready to go: The new LMHB ball bushing from THK

Installing conventional ball bushings requires a considerable amount of time and effort. And, of course, time is money and labour is expensive. However, THK has now launched a new ball bushing that is simply pressed into position — fulfilling a wish that users have held for a very long time.

Two options exist for mounting classic metal ball bushings: They can either be fastened with a snap ring or bolted into position using a retaining plate on the housing. Both types of installation require the housing to be machined. In addition, the work must be carried out with the highest precision, which increases the time required. As a result, machine designers and plant engineers have repeatedly expressed the desire for a less time-consuming solution.

No more bolting — just press in

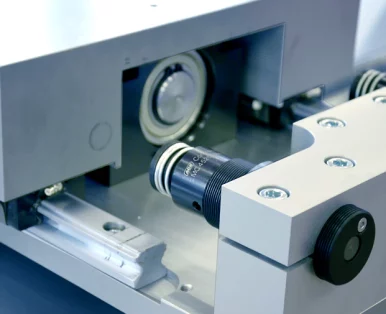

As an international leading specialist in motion technology, THK has made it its mission to resolve this issue. In line with its motto “Every assembly step that is not needed is one too many”, the company—a technology partner of Bachofen—has developed a new type LMHB ball bushing that can be installed on housings quickly, easily and with complete precision. Using a hand press, the bushing can be fitted without using clamping rings or nuts. No other installation work is required.

Metal plate

Ball

Nut

Resin plate

Metal ring

Seal

LM shaft

A sophisticated product concept for perfect operation

THK has also employed innovation with regard to the design principle: The slightly curved metal plates create a spring effect that minimises the play between the balls and the shaft. This results in smooth and quiet movements.

Durable materials

The external dimensions of the new bushing meet the international standards of ISO 10285 series 1. The component takes up little space and thus supports the need for compact dimensions in machine and plant engineering. The component’s plates and ring are made of stainless steel with high corrosion resistance. For the balls, the user can choose between carbon steel or stainless steel versions.

Perfect for every application

The type LMHB bushing from THK is available in six sizes with shaft diameters ranging from 8 to 20 mm. They are already available from Bachofen as of now, with a short lead time. To ensure that no issues occur during the procurement process, Bachofen’s motion technology specialists can be contacted for a consultation.

Discover more products from THK

Areas of application

- Tool construction

- Mechanical engineering

- Packaging industry

An all-round impressive solution

- Simple assembly

- Free of play

- Low-noise operation

- Compact design to ISO standard

Downloads

THK Catalog ball bushing LMHB

Download EN