Efficient use of space and energy: Sliding gate valve from Schubert & Salzer

Space and energy usage is becoming increasingly important when planning production plants. Space is a precious commodity and wherever energy can be saved, the opportunity should be taken. One way of doing so is the compact and energy-efficient sliding gate valves from Schubert & Salzer.

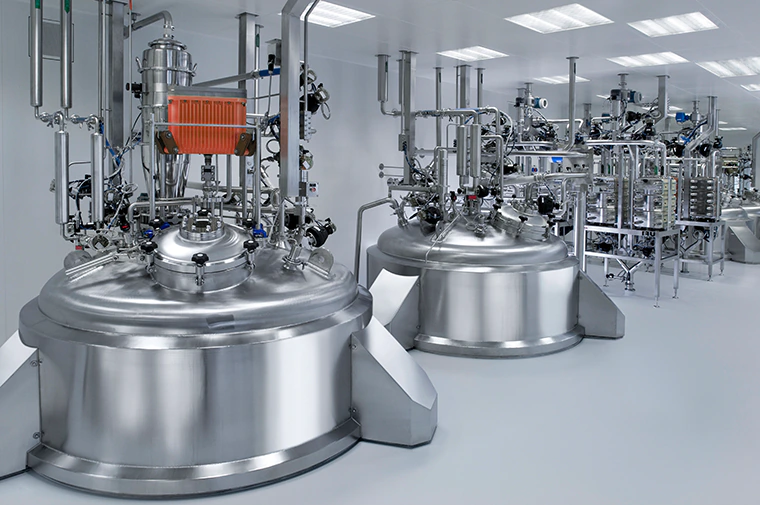

Fewer and fewer growth-oriented companies in industrial production have the opportunity to build on greenfield land. In Switzerland, there is hardly any free space available for industrial use. This forces companies to expand production in their existing buildings, to move to older industrial buildings or even to re-purpose office buildings.

Demanding prerequisites for plant planners

Constrictive spatial conditions limit the scope for planning and require space-saving solutions at all levels. Large control and shut-off valves that take up a lot of space represent a particular headache and are also problematic from an energy point of view: Larger valves require larger drives with correspondingly higher energy consumption.

Conservation of resources

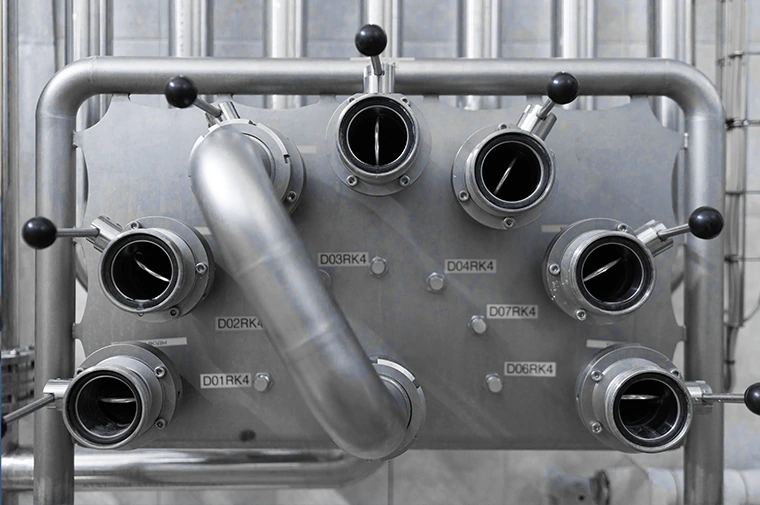

High-performance valve technology specialist and Bachofen technology partner Schubert & Salzer has long recognised the connection between the dimensioning of a slide valve and its energy properties. The compact design of the slide valve significantly reduces energy consumption during component manufacture. Energy in operation is also an important question: The small stroke of the valves allows the use of smaller drives, which require correspondingly less energy. In addition, the control can be set so precisely that only the amount of media effectively required flows through.

Good things come in small packages

The compact design of the sliding gate valves from Schubert & Salzer facilitates installation in confined spaces. The version with intermediate flange, which is also easily accessible, offers a great deal of flexibility. Thanks to their compact, lightweight and low-maintenance design, these valves are perfectly suited for use in hard-to-reach areas of the plant.

At Bachofen, plant builders have the choice:

- The sliding gate valve type 8021 is controlled by a diaphragm. High and low pressures are controlled pneumatically and with high precision. In combination with positioner type 8049, the valve operates reliably and saves energy.

- The sliding gate valve type 8038 is electrically operated and, thanks to the precise drive, controls even the smallest differential pressures with the highest accuracy.

Bachofen has been working with the valve specialist Schubert & Salzer for over 50 years. This results in a concentrated wealth of knowledge, which benefits plant builders in the realisation of space-saving and energy-saving solutions.

Discover more sliding gate valves

Areas of application

-

Chemical industry

-

Energy supply (hot water/cooling water/steam/heating oil)

-

Control applications

-

Sterilisation of water

-

Use in pure and black steam applications

Moving with the times

-

Compact design

-

Rapid response with minimal energy consumption

-

Extremely precise control

-

Lightweight

Reference projects

Energie 360 °

Building technology

Energie 360 °

Building technology

Long live sustainable energy: Solution provider Energie 360°

We have reached the beginning of the end of fossil fuels. The future will be fuelled by climate-friendly energies based on local renewable sources. Energie 360° is driving this development with sustainable energy and mobility solutions.

“Transforming the energy supply is a big challenge. With their well-grounded knowledge of energy efficiency, trusty partners like Bachofen are helping us to reach our targets and effectively leverage environmentally-friendly energy sources.”

Miroslav Cordarov, Energie 360° AG, Senior Project Manager, Energy Systems- Developer

Other focus topics in the area of infrastructure, chemical-, pharma- and foodindustry

Uniformity in diversity: the Turck family of fluid sensors

The world of fluid sensors is bewilderingly wide and diverse. There are countless types, features and designs that make it hard to choose the most suitable component for the...

Hygienic valve technology: in accordance with all norms and standards

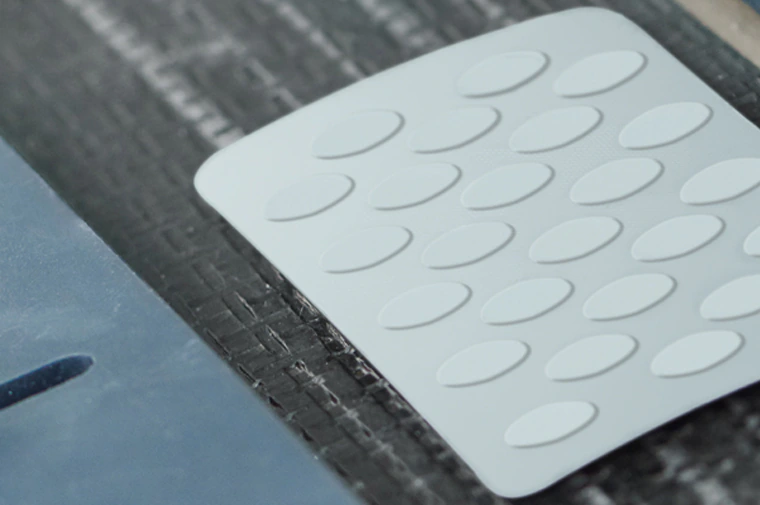

Valve technology ranks among the particularly demanding aspects for industrial food production plant. Valves usually have many standards and norms to fulfil in addition to the high, purely functional,...

Efficient use of space and energy: Sliding gate valve from Schubert & Salzer

Space and energy usage is becoming increasingly important when planning production plants. Space is a precious commodity and wherever energy can be saved, the opportunity should be taken. One...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Dry break and no dead spaces: the 200 Series coupling system from Parker

In hygiene-sensitive environments, liquid cooling is a proven means of preventing processes from overheating. However, line connections must be totally leak-proof, especially when aggressive media are involved. With Parker‘s...

Avoiding disaster: the TN-R42TC-EX RFID write/read head from Turck

Faulty connections in the hose station can become a nightmare for pharmaceutical, chemical and food producers. Reliable monitoring of hose connections, ideally with RFID, is clearly a necessity. The...

Faultless identification: Modular RFID

Automation in the chemicals and pharmaceuticals industry can only be successfully driven forward by intelligent solutions that are able to cope with this complex production environment. The answer to...

Measuring on the tank instead of in the tank: precision load cells from Anderson-Negele

Measuring content in process containers with complex shapes or in horizontal positions is not straightforward. Depending on the tank design, using conventional sensors for fill level measurements can lead...