Hygienic valve technology: in accordance with all norms and standards

Valve technology ranks among the particularly demanding aspects for industrial food production plant. Valves usually have many standards and norms to fulfil in addition to the high, purely functional, requirements. Schubert & Salzer’s special valves belong to a limited category of products that are able to fully meet this requirement.

There are many highly complex regulatory requirements governing food production. Every single component must be designed so as to comply with the hygiene technical standards and minimise risks from contamination. The EHEDG standard prevails, for instance. This standard leaves no room for compromise. The seals and the transitions between them are particularly critical factors, as are the nature and condition of the materials.

Challenges stemming from Regulation (EC) 1935/2004 and/or EHEDG

Regulation (EC) 1935/2004 represents an example of an obstacle to plant approval. This regulation requires that hygiene-compliant shut-off valves and control valves be installed for a variety of processes in order to consistently ensure hygiene safety throughout the production procedure. During the construction of production plant in accordance with the various requirements, it must be ensured that the parts coming into contact with food and beverages be safe from a hygienic perspective. High expectations in terms of accuracy, durability and safety are also placed on control cycles and shut-off functions.

Complying with regulations thanks to Schubert & Salzer’s new 6051 valve range

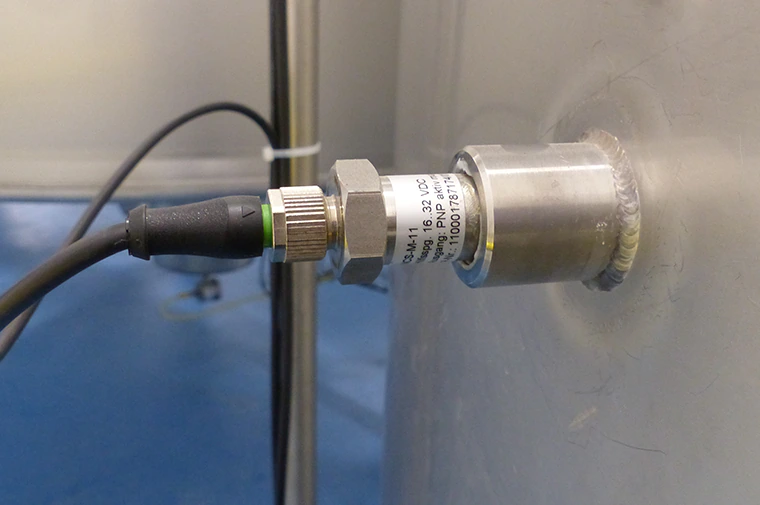

Bachofen’s technology partner, Schubert & Salzer, is one of the few valve technology suppliers that has a number of valve series that fully comply with Regulation (EC) 1935/2004, EHEDG, incl. FDA-compliant seals. The concept behind the 6051 valve range is the elimination of dead space. The materials used were selected on the basis of strict hygiene criteria.

Other valves for versatile applications

The constriction-hose valves 7078, 7071 und 7077 are suitable for processing paste-like, abrasive, aggressive, viscous and granular media. Various FDA-approved hose qualities are available for these valves. Their area of application extends as far as blood plasma processing.

Products that are not only compliant but reliable and long-lasting as well are relevant to future-proof shut-off and control technology solutions. Bachofen possesses the necessary experience and specific application-based expertise to provide you with professional support during the implementation of your applications..

Downloads

Discover more Valves

Discover more products from Schubert & Salzer

Areas of application

-

Universal possible applications in food industry

-

Milk processing

-

Beverage industry

-

Pharmaceuticals industry

-

Cosmetics industry

Reliable service by the book

-

Tested and certified by EHEDG

-

Available both open/closed and as control valve with positioner

-

All seal materials in contact with media FDA-compliant, USP class VI, 1935/2004 and 10/2011

-

EPDM membranes with PTFE protective film, plug made from PEEK

-

Surfaces up to Ra > 0.25 µm (electropolished)

-

Control valve with integrated positioner 8049

Other focus topics in the area of valves and solenoid valves and food

Hygienic valve technology: in accordance with all norms and standards

Valve technology ranks among the particularly demanding aspects for industrial food production plant. Valves usually have many standards and norms to fulfil in addition to the high, purely functional,...

Smart and alert: the COBOTTA compact robot

Due to space limitations, the use of robots often proves difficult. Programming is also a critical factor since, depending on the manufacturer, it can be a very lengthy process....

The safe alternative to the Zener barrier: ATEX-compatible IMX12-SG strain gauge evaluation device from Turck

Strain gauge evaluation devices for use in ATEX zones are a rarity. The divide between ATEX and non-ATEX areas is particularly critical. With the IMX12-SG interface, Turck has unveiled...

Sprinter in ISO Class 3: CSKR cleanroom actuators from THK

Avoiding particles when automating clean room processes is a top priority. With moving machine parts in particular, this key requirement is not that easy to meet since friction causes...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

So nothing flares up in production: TSM temperature sensor from Anderson Negele

Process reliability is the top priority in the food and pharmaceutical industries. Disruptions affect producers’ ability to supply and can damage their reputation. Much depends on the reliability and...

Keeping an eye on the tank: L3 pressure transmitter from Anderson-Negele

If you cannot see what is going on inside tanks in food or pharmaceutical production, the processes are almost impossible to control. To ensure process reliability, the tank contents...

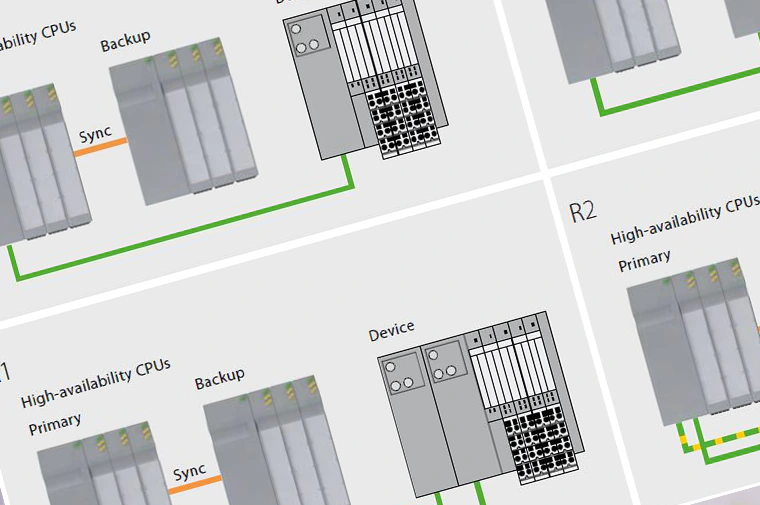

Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet has established itself as the communications standard for factory automation. Vehicle manufacturers and suppliers have been demonstrating the practical suitability of industrial Ethernet-based data exchange for a number...

Measuring on the tank instead of in the tank: precision load cells from Anderson-Negele

Measuring content in process containers with complex shapes or in horizontal positions is not straightforward. Depending on the tank design, using conventional sensors for fill level measurements can lead...

Now remotely controlled by IO-Link: Positioner 8049 from Schubert & Salzer

In plant operation, personnel deployments on site may be time-consuming and awkward in some situations. This also applies to adjusting and maintaining control valves, which are often difficult to...