A quick team player: The Cobotta Pro collaborative robot

Whenever applications require robots and humans to collaborate, productivity usually takes a hit. This is because the safety of operating personnel must always take priority. The Cobotta Pro collaborative robot solves this dilemma: It runs at high speed and reacts sensitively to human intervention.

There are a number of automated work steps that require humans to work alongside a robot. This gives rise to a collision risk. Such risks can be minimised by running the robot at a low operating speed; however, this affects process efficiency and therefore the productivity of the machine — which isn’t a satisfactory outcome for companies facing constant competitive pressure.

Ensuring productivity and safety in one fell swoop

Renowned robot manufacturer and Bachofen technology partner Denso now offers a solution whose name says it all: The new Cobotta Pro collaborative robot intelligently combines high productivity with safety for the operating personnel involved in the process. When there is no human in the vicinity, it performs to its fullest capability and travels at the maximum TCP (tool centre point) operating speed of 2500 mm/s. It excels with a repeat accuracy of ±0.04 mm. If a person approaches, the time required to stop is automatically reduced. The danger of the robot and the operator getting in each other’s way is reduced to practically zero.

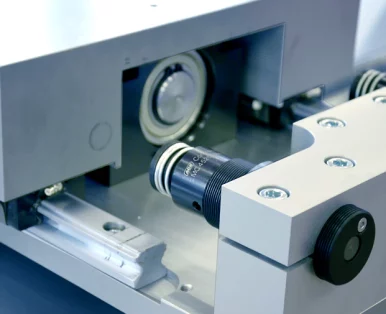

Sensor technology at its best

Proprietary sensors for torque, speed and range monitoring are the core element of this safety concept. These are integrated in all axes as standard. The highly sensitive contact sensors installed under touch-sensitive soft silicone pads ensure additional safety.

Highly adaptive thanks to "direct teaching"

The Cobotta Pro performs simple routine tasks such as pick & place quickly and precisely, but is also the perfect robot for complex multi-stage assembly and testing processes. Denso has developed the concept of “direct teaching” for such tasks involving the very highest precision requirements. In this process, the robot learns independently what it has to do: For example, it is able to memorize a given route, perform fine tuning with an accuracy of 0.1 mm and master numerous other learning situations. The “Blockly” visual programming language is used for this purpose. An upgrade with the “Mech-Eye” 3D image recognition system and the use of the “AI Imitative Learning” software make the Cobotta Pro an attentive, thinking and flexible employee.

And it’s not just the robots who embody these principles, but also the people who design them: The automation and robotics specialists at Bachofen likewise champion listening attentively, adaptive thinking and responding flexibly to customer requests. Collaboration is just as important in terms of consulting and technical support as it is with the new Denso robot.

Discover more collaborative robots

Discover more products from Denso

Areas of application

- Use in class 5 clean rooms

- Assembly and testing work

- Material handling

- Packaging

Playing it safe with productivity

- A robot that sees, thinks and moves accordingly

- Safe, fast and accurate

- Blockly intuitive programming language

- New concept of "direct teaching"

Downloads

Denso Flyer Cobotta

Download EN