Bringing up the curtain on improved safety: New high-capacity safety light grids from Banner

Although ensuring machine safety often has no direct benefit on productivity, it is nonetheless too important to be ignored. Accidents involving personnel can have dramatic consequences for those affected and damage a company’s reputation. To uphold this commitment to safety, Banner has taken another step forward by launching a new generation of safety curtains.

Responsibility for the safety of machines and plants lies solely with the designers and operators: This applies in Switzerland as per legal regulations and the Swiss National Accident Insurance Fund (SUVA). Companies should also take this view, instead of simply making reference to the safety and health of their employees with an empty phrase in their mission statement. It’s an immutable truth that procuring safety equipment incurs costs and does not impact profit directly. Indirectly, however, it most certainly does: Industrial accidents are not just tragic from a human perspective, but can also have a negative impact on a company’s reputation. And that in itself is a good enough reason to use the latest technology to guarantee machine safety.

Greater safety through technical innovation

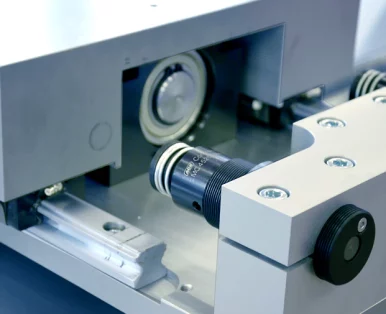

The type S4B safety light grid marks the start of a new product range from Bachofen’s technology partner Banner, which seeks to redefine machine safety with its new line. The renowned sensor technology and safety specialist has made enhancements at various levels: New components and an innovative mechanical layout strengthen the safety light grid and improve its resistance. It can be installed quickly with a “click mechanism”, is easy to operate and can perfectly detect hands thanks to its high resolution of 30 mm. Thanks to end-to-end detection in lengths from 300 mm to 1800 mm and a range of up to 12 metres, the range of applications is virtually limitless.

Three-colour LED with multiple functions

Another highlight of the new type S4B safety light grid is its multifunctional three-colour LED. This helps the installer to correctly align the curtain and permanently displays the alignment status. Additionally, as a notable new feature, the LED will emit a warning signal if an issue is detected: For example, if the radiation intensity decreases due to misalignment or the window becomes dirty. Banner’s new type S4B safety grid also fits easily into fully automated environments: Warning signals can be transmitted via an interface to an SMS or another monitoring system – an interesting feature, especially with regard to predictive maintenance.

First product in a whole new range

Banner is working hard on expanding its new series of high-load safety light grids. One thing is certain — they will take a prominent position in the Bachofen range for machine safety.

Buy safety grids in the shop

Discover more products from Banner

Areas of application

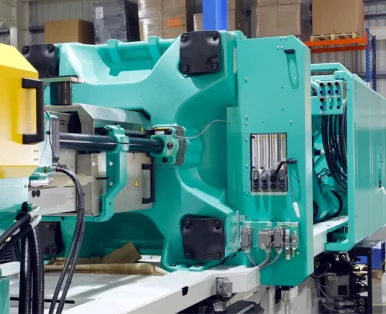

- Machines

- Robot cells

- Presses

- Palletising systems

Satisfying the very highest safety requirements

- Simple assembly

- Height from 300–1800 mm

- Distance up to 12 m

- LEDs for alignment and service

Downloads

Banner Flyer S4B

Download EN