Home > Construction industry > Distance yourself from mediocrity: the Turck uprox® 3 factor 1 sensors

Distance yourself from mediocrity: the Turck uprox® 3 factor 1 sensors

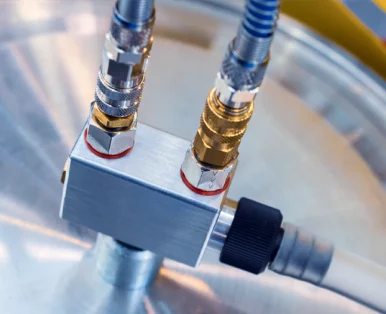

Inductive sensors, for applications in special machine engineering and other demanding fields, should ideally have high switching distances, be compact and form a key element for reliable machine and plant operation. The two uprox®3-series minis from Turck meet all of these requirements in every respect.

To meet customers’ requirements, machine and plant manufacturers receive requests at various levels, including increasingly greater production capacity and maximum plant availability. And the ever smaller scales required in machine engineering are a further consideration. Not to mention cost – another critical factor – how can savings be made without compromising on function?

It couldn’t be any more compact: 4 mm diameter or M5 version

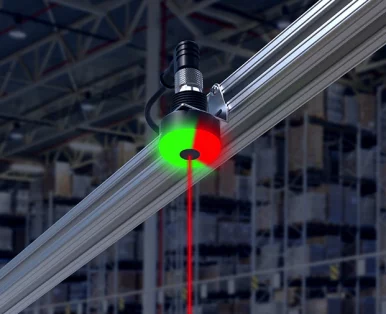

The latest generation of the uprox®3 series includes both the extremely compact smooth-barrel types with 4 mm diameter and the M5 threaded sensors. Thanks to their high switching distance, the inductive sensors can be mounted, fully flush, at a safe distance from the target. This means they are protected effectively against mechanical damage even when operating in extremely high-frequency conditions. And they are not picky when it comes to the targets, having proved themselves equally on steel and aluminium targets.

uprox®3: high switching distances and special functions included

uprox®3: high switching distances and special functions included

Streamlined range and communication ability thanks to IO Link

While, in many other fields, a wide range of products is seen as an advantage, in the case of the uprox®3 model series, the opposite is true: just a few types are required to make all conceivable applications possible. The streamlined range simplifies the sensor technology concept and reduces storage and maintenance costs. The uprox®3 IO Link brings further type productions by offering a range of configuration options for switching distance, electric output and other functions. It also generates a real wealth of other valuable information, for example for predictive maintenance. Connecting the sensors to Turck IO Link-compatible couplers makes wireless operation possible. What’s more, in this configuration, they also make it possible to identify mobile units and tools.

As a machine or plant manufacturer, the new uprox®3 series can help you to gain maximum information with minimum effort. Simply contact Bachofen for advice from one of our technical specialists.

Discover more products from Turck

Areas of application

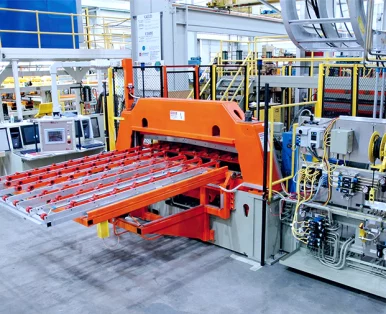

- Vacuum gripper for picking up and moving metal sheets

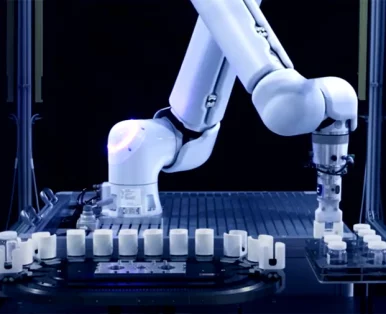

- Predictive maintenance (IO Link)

- Identification (IO Link)

High performance in mini format

- Maximum switching distance

- Fully-flush mounting

- Smallest M5 and 4 mm diameter smooth-barrel designs

- Welding spark-resistant M8, M12 and M18 variants with PTFE-coated housings

- Excellent EMC properties

- Maximum welding strength

- IO Link for various configuration options

- Type reduction/storage optimisation

- Reduction of maintenance costs and effort