Home > Construction industry > Eagle eyes in the compressed air network: flow sensors from EGE

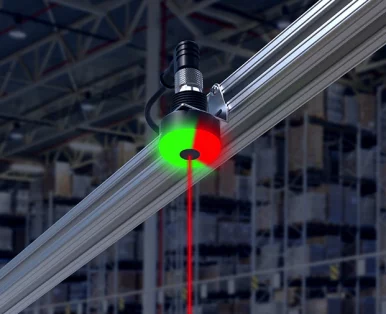

Eagle eyes in the compressed air network: flow sensors from EGE

Compressed air is expensive. One cubic meter can easily cost 10 to 20 Swiss centimes. Too much to waste. Flow sensors from EGE with IO Link display leakages immediately and provide continuous, detailed consumption information at individual production points in the process or at manual work stations.

Leaks in compressed air networks drive up your costs on two levels: on the one hand, you’re paying for the loses themselves, while on the other, the compressor is constantly running in high-performance mode and consuming a huge amount of energy. And that’s not all – running the compressor continuously causes wear, which could lead to unscheduled maintenance work. So, installing flow sensors is an investment that pays off on many levels.

Cost-optimised control of the compressed air network

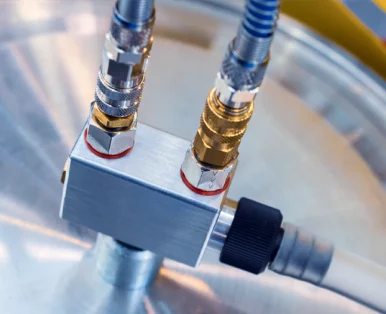

The sensors with IO Link interface from EGE can be integrated into almost any industrial application and infrastructure thanks to their different adaptation options and easily configurable parameters. They allow you to manage and control your compressed air network with an eye on cost optimisation, while also increasing the network security to an enormous extent. For smaller pipe diameters up to G1 ½”, EGE offers inline measuring devices, and for larger pipe diameters up to 200 mm, EGE has models available in the form of immersion sensors.

Connection with the PLC via IO Link

The EGE sensors from the LDN, LDV and LDS range clearly display the compressed air consumption of the attached plant part or tool on the six-digit display. The values are read by a PLC via the IO Link interface. And there are also two programmable outputs to cover all your needs, together with a non-resettable modification counter to prevent tampering.

A range of functions for comprehensive control

The flow sensors with IO Link from EGE are real all-rounders, offering a range of functions, including consumption display, dosing function, temperature recording, pressure measuring and switch-off delay. And that’s not all, as these devices also boast a hysteresis function. The sensors themselves are easy and convenient to configure and use via the IO Link interface.

Your Bachofen contact has a real feel for customer-specific needs and applications and will cater to your needs by offering expert support to find you a tailored solution for a secure compressed air network.

Discover more products from EGE

Areas of application

- Compressed air systems in industrial production

Air pressure under control

- Leak detection

- Additional pressure and temperature measurement

- Manipulation detection

- Comfortable adjustment via IO-Link interface