Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the assembly of piping systems and is now introducing Carstick+ – a quick connection that can be used for a wide range of housing materials.

Space and time are two factors which equipment manufacturers are constantly having to grapple with. For example, the market demands designs that are as small as possible. This means that when developing the equipment concept, every possible opportunity must be taken to save space. Also, that old and familiar maxim “time is money” still very much applies. In fact, for assembly in particular, speed is very much of the essence because manpower is expensive. The ideal is for assembly processes to be automated to the highest possible degree. And, among other things, this requires components that are suitable for automation.

Designed for tight spaces

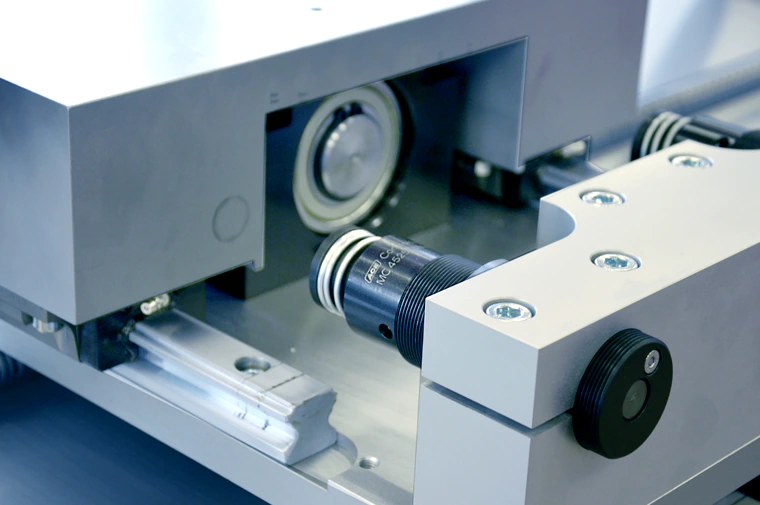

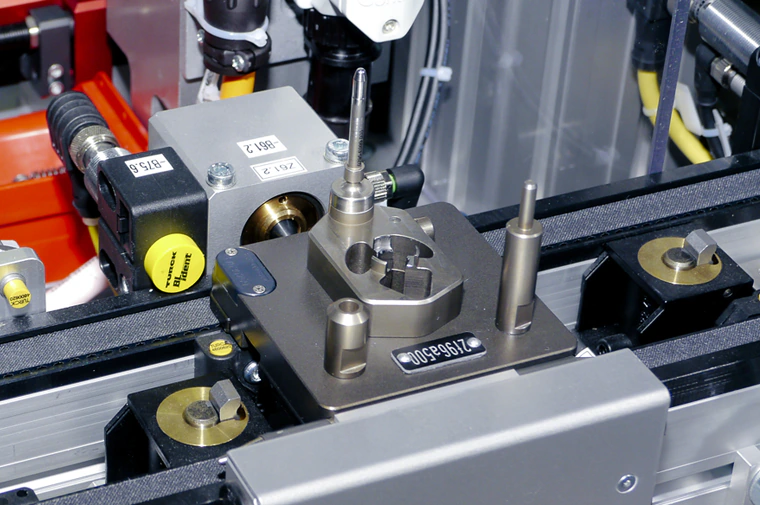

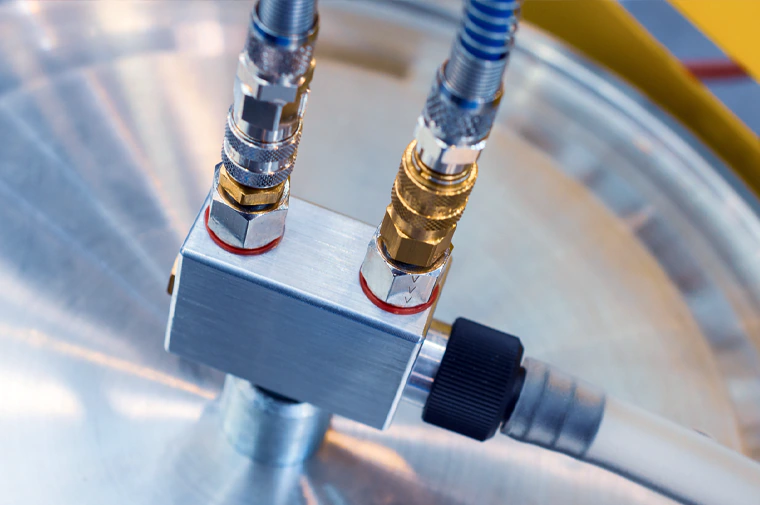

The Carstick® push-in cartridge from Parker for fastening hoses or for connections in piping systems meets the demand in terms of saving space and time. The idea behind the product brand is that if the connection is only being made once, then a thread is a step too far. Carstick® for brass and aluminium housings is very popular with machine and equipment designers because the component can still be used where space is too tight for screwed connections. Carstick cartridges can also be assembled, if required, close together and without the need for tools which take up a lot of space.

Carstick+: a tight fit even in non-elastic polymers

With Carstick+, the connection specialist and Bachofen technology partner Parker has further enhanced the proven Carstick concept. The new push-to-connect cartridge requires significantly less effort when inserting than its predecessor and can therefore be pressed into thinner-walled components and more complex designs. The range of applications has also been expanded: Carstick+ is suitable for a large range of housing materials, including non-elastic polymers. The cartridge is removable without damaging the housing, making it reusable.

Automation reduces assembly costs

The most compact cartridge on the market is huge in terms of assembly efficiency. The one-piece component can be pressed in two to three times faster than conventional products and has a feature that should be popular in particular with high-volume equipment manufacturers: Carstick+ allows the pressing in of connections to be automated, which significantly reduces assembly costs. This gives the Carstick+ an advantage over both conventional screw connections and other cartridges.

Bachofen can provide 100% solution-oriented advice for users seeking to increase productivity by up to 75% with the new Carstick+. This is based on extensive expertise in the process management of compressed air and fluids.

Downloads

Discover more Carstick+

Discover more products from Parker

Areas of application

-

Cooling application, power electronics

-

Drinks dispensers

-

Coffee machines

-

Medical respiratory devices

-

Compact distribution blocks

-

Compressed air distribution

Small but clever

-

Compact design: smallest cartridge on the market

-

Automatic processing delivers assembly efficiency

-

Fluidic integrity

-

Can be removed without damaging the bore

Other focus topics in the area of machine tools, machines, installations and equipment

Lights that speak: the new WLS27 pro-lights from Banner

When monitoring machinery, processes, actions or user behaviour, speed and clarity are paramount. The most efficient medium for these purposes is light. With its new WLS27 Pro-lights that are...

Out into the field: CODESYS-3 controller TBEN-Lx-PLC from Turck

Some machine manufacturers are still hesitant when it comes to relocating controllers into the field, even though the benefits of decentralization are very clear. The CODESYS-3 controller TBEN-Lx-PLC from...

One IP address for an entire sub-network: all thanks to beep from Turck

With the TBEN-S, TBEN-L and FEN20 fieldbus modules, Turck is opening up new possibilities for machine and plant manufacturers. Each device on a network can be reached via an...

Tiny but mighty: the new HRG miniature roller guide from THK

A linear guide should take up minimal space but also deliver maximum performance. This contradiction inevitably leads to compromises when evaluating the options. But this is now a thing...

Solutions and expertise to meet your needs: Bachofen Engineering

As a rule, manufacturers come under a lot of pressure in terms of time, costs and innovations. And on top of that, they are faced with consistently high customer...

Procurement made easy: Bachofen safety technology from a single source

There are many aspects to the safety of machines, plant and vehicles. However, designers and operators have more important things to do than be setting up an evaluation process...

Prime example for industry 4.0: the machine thinks along with you

Is the tool suitable for the next processing step and when is the next service due? This information is crucial for ensuring that manufacturing runs smoothly with no long...

Prevention is better: monitoring using the Edge Gateway from Turck

Many operating faults in machinery and systems go undetected until the process itself starts to falter. If the operation was permanently monitored, any functional faults that were about to...

Diversity and quality combined: Parker Rectus connection technology

Need to disconnect fluid connections quickly, cleanly and without any tools? Then look no further than the Rectus couplings from Parker. Parker has the right coupling for every conceivable...