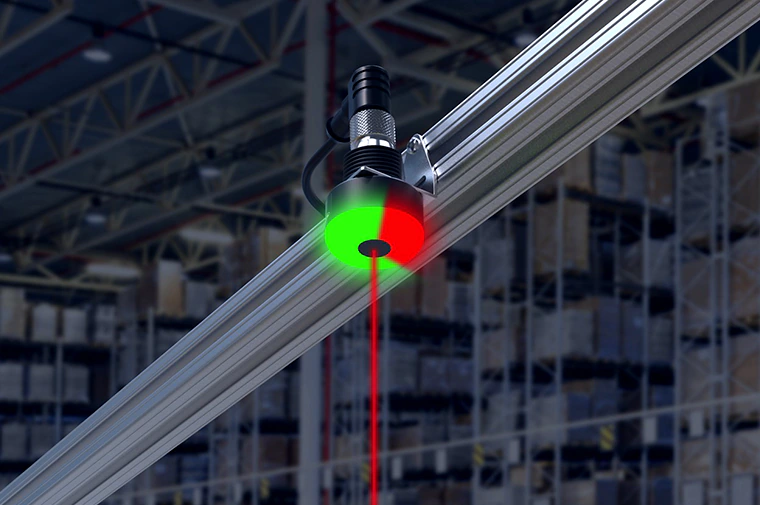

No more wasted compressed air: Air Saver Unit from Parker

Studies show the about half of compressed air in industrial plants is lost ineffectively. Evidently, the handling of this operating supply is not very tightly monitored. However, rapidly rising energy prices have resulted in an urgent need for action. It is high time to deploy the Parker Air Saver unit.

In many production facilities, plant and machine employees are barely aware that compressed air is a valuable operating supply, just like electricity. This medium is generally fed to the individual workstations via ring networks and is available there as a matter of course. It often remains unnoticed that—according to study results—up to 30% of the energy-intensive compressed air produced is lost due to leaks in the distribution system. The use of compressed air for non-productive activities is also very significant, accounting for a further 15 to 20%. And when the pressure is higher than it needs to be, that is simply a waste.

Halving of compressed air consumption by pulsing the air flow

Compressed air systems have enormous energy-saving potential, which cost-conscious companies can exploit with little investment required. Bachofen technology partner Parker can lend a helping hand with the Air Saver Unit, which can reduce compressed air consumption by up to 50%. The air-saving unit is based on the fact that pulsed air requires significantly less energy than a continuous air flow. The device pulses the compressed air flow on and off extremely rapidly. This has the effect that the compressed air accumulator has to be refilled less often.

Clean design for hygiene-sensitive applications

The Parker Air Saver can be installed in any compressed air system with little installation effort and does not require any additional controls. It can also be retrofitted at any time. Thanks to its hygienic design with smooth, easy-care surfaces, the unit is also suitable for use in air pressure systems in the food and pharmaceutical industries.

As one of the market leaders in advanced valve technology, Parker stands for quality, precision and reliability. With technical support and their specialist knowledge, Bachofen consultants will ensure that these attributes are used to their fullest in your application.

Discover more products from Parker

Areas of application

-

Cleaning with blowing air in manufacturing processes

-

Approved for applications in the food and pharmaceutical industries

-

Blow guns in assembly lines

-

Compressed air control on pneumatic automation systems

The benefits are a breath of fresh air

-

Up to 50% saving of compressed air

-

Easily integrated into any system

-

Long service life

-

Clean, FDA-compliant design

Downloads

Other focus topics in the area of machines, installations, equipment and machine tools

Why go on long trips when you don’t have to? Remote maintenance with Cosy+ from Ewon HMS Networks

Work trips by engineers and service technicians can quickly become expensive. And it takes quite a while before the maintenance is completed or the machine defect is repaired. We...

Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable...

Bridges across space and time: Be where the action is with remote access

Carry out maintenance work and identify faults before they arise, across any distance and at any time: this vision is becoming a reality in the age of Industry 4.0...

Increased energy efficiency in the compressed air system:

The operation of compressed air systems is energy intensive. This makes it all the more important to constantly control the flow rate and, if necessary, take appropriate steps to...

Flexible arc guides: practice on the right track

Machine manufacturers are required to fulfil increasingly specialised requirements. Yet they are also under pressure in terms of costs. The solution to this dilemma is multifunctional standard components that...

Monitoring and visual display in a single device: The new K30 Pro optical sensor from Banner

Monitoring a process is one thing — displaying its status is another. To date, a separate device has been required for each of these two functions. Now, however, automation...

Coupling at the touch of a button: improved safety with parker rectus

Frequent changes of staff and the use of different tools are latent risk factors when it comes to connecting compressed-air lines. Thanks to the push button safety coupler from...

Modbus-compatible and networked: electric actuators from Valpes

The ability of measurement and control systems to communicate is of central importance to the safe operation of systems. Electric actuators from Valpes can be configured and controlled using...

Out of the control box: towards decentralised concepts

In the world of Industry 4.0, modularity is gaining increasing importance in the manufacture of machinery and systems. This development is also promoting the decentralisation of I/Os and control...

Non-contact precision measurement: Turck DR series radar distance sensors

There are a variety of processes where measurements can only be taken reliably and safely at a distance. Harsh environments are an example of these. Factors internal to the...