Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable production: They are economical in energy consumption, generate little noise and allow comfortable handling thanks to their ergonomic design.

The use of compressed air for cleaning purposes is indispensable in the operation of machines and plants as well as in many other areas. Compressed air removes dust, dirt and other surface deposits very quickly. In contrast to cleaning with rags, cleaning equipment and detergents, compressed air is a gentle method which, when used properly on sensitive surfaces, causes no scratches or other damage. Eliminating cleaning agents and other chemicals not only reduces costs, but also reduces the environmental impact.

Not all compressed air is made equal

There are marked differences between the compressed air systems available on the market, especially in terms of air consumption, energy consumption and system quality. Industrial production companies are finding themselves under increasing pressure when it comes to energy consumption, so this aspect deserves special attention.

Parker Legris guarantees quality, personal safety and sustainability

With compressed air blow guns from Bachofen technology partner Parker Legris, the power to be more sustainable is literally in the user’s hands. This is because these devices have been methodically designed for performance, environmental friendliness and personal safety. The blow guns generate a strong air flow, which can be regulated via a selection of nozzles and can also be directed specifically into hard-to-reach areas. They also meet the highest requirements for health protection and the safety of operators. Key points here include noise reduction, pressure limitation when closing the nozzle and lateral air pressure discharge in the event of excessive backflow pressure in the nozzle. Parker Legris compressed air blow guns are easy to handle and light enough that the operator experiences no fatigue, even over long periods of use.

Realise potential energy savings with Bachofen

Bachofen offers machine and plant operators a wide range of compressed air blow guns suitable for a variety of applications: classic pistol grip blow guns, in-line blow guns and special versions for applications in the food industry, in semiconductor production and other sectors such as the electrical, metalworking and woodworking industries. The latest highlights: the energy-saving versions that can result in savings of up to 40%. To achieve the optimum energy balance, Bachofen assembles the combination of nozzle, gun and spiral hose that makes most sense for the respective application. So the potential savings don’t vanish into thin air.

Buy air blowguns in the Shop

Discover more products from Parker

Areas of application

-

Cleaning machines

-

Cleaning electronic equipment

-

Woodworking

-

Cleaning vehicles

Efficiency is in the air

-

40% energy saving when using the energy-saving versions

-

Powerful flow with precise, stepless regulation

-

Safety-focused design for comprehensive personal protection

-

Lightweight and easy to use

-

Versatile range with a wide variety of designs and nozzles for optimum performance

Downloads

Reference projects

Enterprise du Gaz S.A.

Building technology

Wäsche-Perle AG

Building technology

Bernmobil

Building technology

Enterprise du Gaz S.A.

Building technology

Advanced technology in the realm of the dinosaurs: plant engineering company Entreprise du Gaz

How does an ordinary technical company in the public sector become a dynamic regional leader in the fields of heating, sanitation and drinking water management? The Porrentruy-based company Entreprise du Gaz S.A. has shown the way.

«The ability of our suppliers to deliver is enormously important for us and the price also plays a role, because we are often under cost pressure. We see Bachofen as a highly respectable and fair procurement partner at pricing level, with whom we have the guarantee that the quality is right. »

Marcel Meyer, CEO, Entreprise du Gaz S.A.- Developer

Wäsche-Perle AG

Building technology

Wäsche-Perle's full service irons things out for the hospitality industry

Successful hotel and restaurant businesses in the Bernese Oberland/Central Switzerland region do everything in their power to spoil their guests. Doing the laundry doesn’t come into it. They leave this to the specialists at Wäsche-Perle, giving them time to focus on the essentials.

“I thought it was great that the Bachofen consultant came to see us several times during the facility expansion to make sure that everything was going well during the installation of the Transair compressed air distribution system. Now our technician has the system perfectly under control.”

Lukas Röthlisberger, Managing Director of Wäsche-Perle AG- Developer

Bernmobil

Building technology

Tailwind for Bernmobil: compressed air by the kilometre

Bernmobil shines, with its punctuality, reliability and safety. The maintenance of the vehicle fleet plays a key role in this. With a comprehensive refurbishment of the compressed air system, the company has brought its workshops in line with the state of the art. And all this without interrupting operations.

“If building services equipment such as the compressed air supply needs to be replaced during ongoing operations, good coordination is essential. Bachofen’s flexibility was a significant factor in our ability to execute this complex renovation project on time.”

Michael Tièche, Head of Facility Management at Bernmobil- Developer

Other focus topics in the area of machines, installations, equipment and machine tools

Hot tip for mechanical engineers: motor-driven proportional valve

Handling hot liquids can cause manufacturers to break out in a sweat, as it poses particular challenges for valve technology. That is why those who are able to keep...

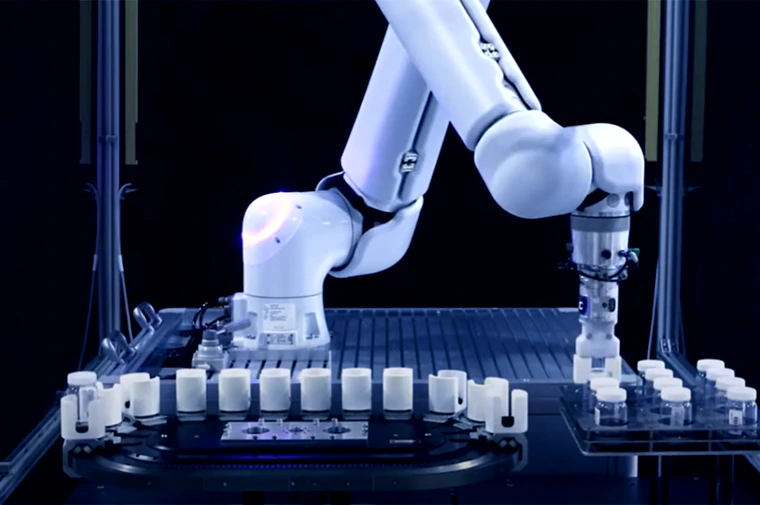

A quick team player: The Cobotta Pro collaborative robot

Whenever applications require robots and humans to collaborate, productivity usually takes a hit. This is because the safety of operating personnel must always take priority. The Cobotta Pro collaborative...

Binary bottleneck removed: taking the last metre

Binary interfaces designed for pure switching data are a hindrance to the integration of data flows in machinery and systems as far as Industry 4.0 is concerned. IO-Link closes...

External linear scale now a thing of the past: the new THK SHS-LE linear guide

In mechanical engineering, complex component-installation steps combined with a notable lack of space remains an ongoing challenge. In addition to being more space-saving in its design, the new THK...

Bringing together OT and IT: using HMS gateways and communicator

Operation Technology and Information Technology normally follow separate paths. For machine and plant manufacturers, this incompatibility is a real headache. But this is now a thing of the past:...

Tiny but mighty: the new HRG miniature roller guide from THK

A linear guide should take up minimal space but also deliver maximum performance. This contradiction inevitably leads to compromises when evaluating the options. But this is now a thing...

Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the...

Bridges across space and time: Be where the action is with remote access

Carry out maintenance work and identify faults before they arise, across any distance and at any time: this vision is becoming a reality in the age of Industry 4.0...

Out of the control box: towards decentralised concepts

In the world of Industry 4.0, modularity is gaining increasing importance in the manufacture of machinery and systems. This development is also promoting the decentralisation of I/Os and control...

Non-contact precision measurement: Turck DR series radar distance sensors

There are a variety of processes where measurements can only be taken reliably and safely at a distance. Harsh environments are an example of these. Factors internal to the...