Home > Automation technology > Why go on long trips when you don’t have to? Remote maintenance with Cosy+ from Ewon HMS Networks

Why go on long trips when you don't have to? Remote maintenance with Cosy+ from Ewon HMS Networks

Work trips by engineers and service technicians can quickly become expensive. And it takes quite a while before the maintenance is completed or the machine defect is repaired. We also owe it to the climate to exercise restraint when travelling by air. The sustainable solution is remote maintenance with Cosy+.

Remote access to plants and machines at locations in other parts of the world has opened up a new dimension for carrying out maintenance and repairs: Travel costs for service staff are eliminated, functional checks and maintenance interventions can be performed any time at short notice, and downtimes caused by malfunctions can be reduced enormously.

Remote maintenance also has downsides

Remote access is not without risks, however. Issues include the security of data transmission networks, protection against hackers, the reliability of the hardware and the competence and trustworthiness of authorised personnel. Any remote access solution must always meet the most stringent safety and security requirements currently in place. If not, production is put at risk, which presents an existential threat.

The reputation of the system provider is key

With the new Cosy+ device generation from Ewon, remote pioneer and Bachofen technology partner HMS Networks is making remote access to plants and machines safer and easier. Cosy+ establishes a protected VPN connection between the machine and the service technician. Communication is encrypted via Talk2M, a cloud-based remote access service developed specifically for industrial applications that guarantees state-of-the-art security. Only two mouse clicks are required to access the PLC, the HMI or another device installed in the plant. The intervention can be carried out from anywhere using a desktop, laptop, tablet or even a smartphone.

Secure from hardware to the cloud

The core element of trust is the hardware security embedded in Cosy+, which meets the highest IoT standards. Examples of this are the secure boot sequence, which only accepts code signed by Ewon, and the built-in certified security chip. The machine LAN ensures that users can access only the target systems during remote maintenance and has no effect on the existing network. A digital output indicator shows activity on the remote connection. Detailed logs and reports provide comprehensive monitoring of remote maintenance.

Bachofen as the obvious partner for secure remote access solutions

“Connecting Devices” is the motto of Ewon manufacturer HMS. Bachofen uses the slogan “Connecting Experts”: Close cooperation between machine designers and the Bachofen remote application specialists results in remote access solutions that will remain sustainable long into the future. They make economic sense, they protect the environment by reducing air travel and they are socially responsible by making customers happy.

Buy Ewon remote maintenance module Cosy+ in the shop

Discover more products from HMS

Areas of application

-

Remote monitoring, control and maintenance of machines and plants

-

Online access to all operationally relevant machine components

-

Online analysis and evaluation of machine data

Secure remote maintenance

-

Simple setup

-

No in-depth IT skills required

-

Highest level of safety according to ISO27001

-

Cybersecurity partnership with NVISO

-

High-performance Talk2M VPN service

-

External key switch for local control of remote access by the end user

Other focus topics in the area of machines, installations, equipment and machine tools

Manpower: too good for repetition and routine

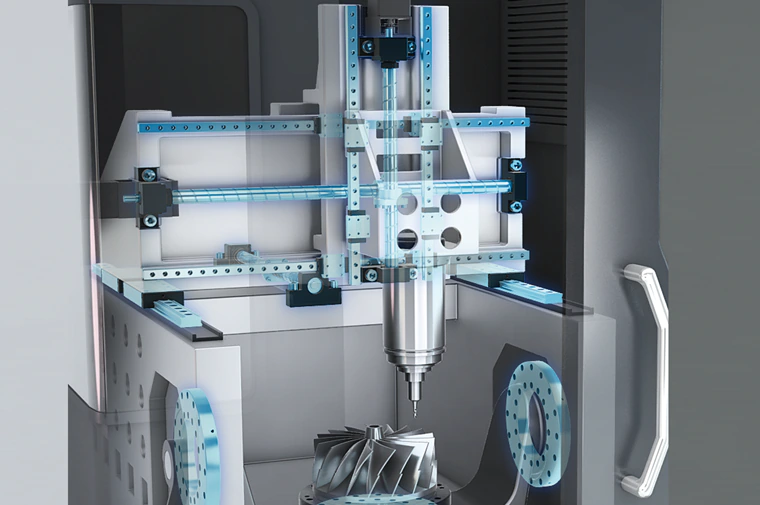

High-performance machine guarantee a high level of productivity thanks to efficient production. This is compromised if an operating person is required to load and unload the machine. DENSO robots...

On the move at high speed: the new BSM ball screw from THK

When speed is required, conventional ball screws quickly reach their limits. Traditional types have a DN value of between 60,000 and 120,000. THK’s new BSM ball screw exceeds these...

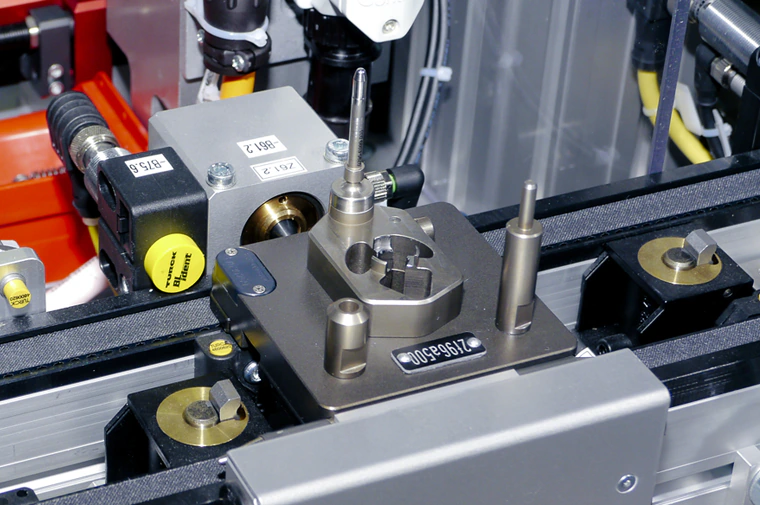

Prime example for industry 4.0: the machine thinks along with you

Is the tool suitable for the next processing step and when is the next service due? This information is crucial for ensuring that manufacturing runs smoothly with no long...

Prevention is better: monitoring using the Edge Gateway from Turck

Many operating faults in machinery and systems go undetected until the process itself starts to falter. If the operation was permanently monitored, any functional faults that were about to...

One IP address for an entire sub-network: all thanks to beep from Turck

With the TBEN-S, TBEN-L and FEN20 fieldbus modules, Turck is opening up new possibilities for machine and plant manufacturers. Each device on a network can be reached via an...

Bridges across space and time: Be where the action is with remote access

Carry out maintenance work and identify faults before they arise, across any distance and at any time: this vision is becoming a reality in the age of Industry 4.0...

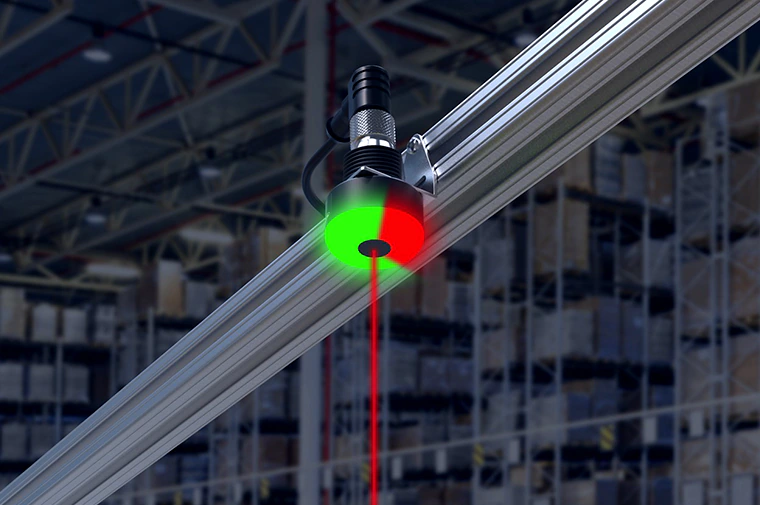

Optical sensor: green light for LED

Machine are carrying out increasingly complex functions and are increasingly networked, reflecting Industry 4.0. This also results in higher demands on the optical sensors. The future lies in LED...

Bringing together OT and IT: using HMS gateways and communicator

Operation Technology and Information Technology normally follow separate paths. For machine and plant manufacturers, this incompatibility is a real headache. But this is now a thing of the past:...

Monitoring and visual display in a single device: The new K30 Pro optical sensor from Banner

Monitoring a process is one thing — displaying its status is another. To date, a separate device has been required for each of these two functions. Now, however, automation...

Lights on for increased productivity: Industrial lighting range from Banner

Even though your workplace might be filled with the brightest minds, if the lighting isn't right, the risk of mistakes and quality losses increases enormously. What's more, outdated lamps...