Home > Motion technology > Don’t get bent out of shape: supreme heavy-duty telescopic slides

Don’t get bent out of shape: supreme heavy-duty telescopic slides

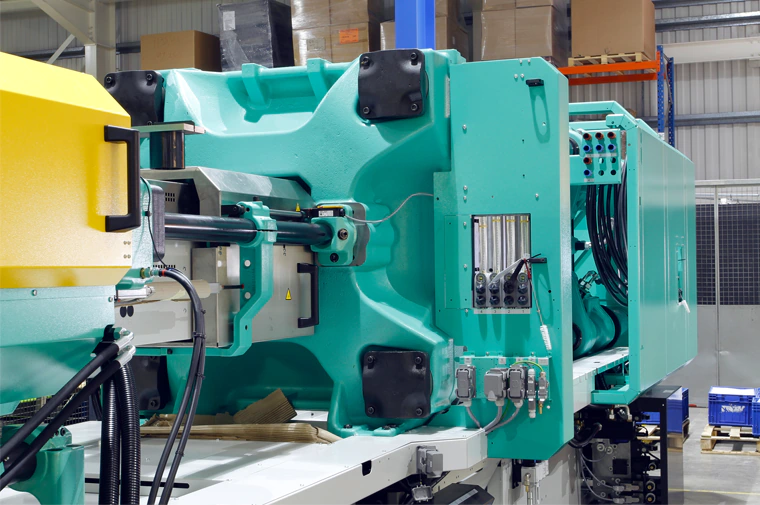

Every composite system is only as good as its weakest part. This old truth applies in particular to the operation of commercial and railway vehicles. For there is barely any other sector in which the physical loads are as high as in the vehicle industry. The Supreme heavy duty telescopic slide is an impressively heavy unit.

Commercial and railway vehicles as well as mobile machines used outdoors must be able to operate under the toughest of framework conditions. This includes extreme weather as well as vibrations and shaking. Depending on the place of operation, e.g. military deployment, difficult terrain might also be a challenge. For emergency services vehicles, such as the fire brigade and HAZMAT, or protection and rescue, reliable operation of the equipment can be the difference between life and death. Every single part counts.

High rigidity even under extreme loads

The newly developed Supreme heavy duty telescopic slides developed by the Dutch manufacturer Thomas Regout International B.V. are tough and reliable, and can handle a temperature range from -30°C to +110°C. With their high bending strength and low deflection, they can be used wherever very high loads have to be moved precisely and smoothly and high rigidity is required. The contact on the ball bearings at four points allows for a slight preload on the slide and thus an additional increase in rigidity.

Maximum 1 to 2% deflection in relation to slide length

The load capacities are based on a maximum deflection of 1% of the slide length with complete load in extended state. A still very low deflection of max. 2% is to be expected with extension distances of 150 to 200%. The load capacity always depends on the profile and slide type. For example, the double T design of the slide supports a very rigid and stable guide with minimal deflection. Slide lengths of up to 1,200 mm are possible.

The right material for every application

Depending on the application, the Supreme telescopic slides are available in steel, aluminium or stainless steel versions, as well as in standard or two-way extension options. The steel Supreme models are electrogalvanised, RoHS-compliant and have a layer thickness of 10 to 12 µm. With the aluminium slides, the ball cage is made of stainless steel as standard (V4A). The Supreme stainless steel slides (1.4404) are highly corrosion resistant. This ensures a guide with low-wearing tracks, which proves its worth above all for demanding industrial applications such as battery trays.

The Supreme range from Thomas Regout includes 26 different models with a total of 520 different extension distances up to load capacities of 2,000 kg per pair. Bachofen ensures that making the right choice doesnʼt become a burden. With application-specific advice and competent technical support with configuration.

Downloads

- Brochure : Supreme

Shop now telescopic rail

Areas of application

-

Special vehicles (e.g. fire brigade)

-

Railway vehicles

-

Interior construction

Important advantages

-

High load capacity with minimal deflection: max. 1% with full extension, max. 2% with over-extension)

-

Load capacity up to 2,000 kg

-

Robust and compact design

-

Available as partial, full and over-extension (up to 200%)

-

Available in steel, aluminium and stainless steel variants

Other focus topics in the area of transport, traffic, vehicles

Don’t get bent out of shape: supreme heavy-duty telescopic slides

Every composite system is only as good as its weakest part. This old truth applies in particular to the operation of commercial and railway vehicles. For there is barely...

Easy rider in a compact design: miniature RSX linear guide from THK

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The...

Up to the harsh conditions of the road: stainless steel couplings from Parker

The pneumatic and hydraulic systems in public transport vehicles are exposed to particularly harsh conditions, as are the lines and couplings that play a central role in these systems....

No uncertainty on the rails: Rectus quick-release couplings

When operating railways, each individual component must be reliable to ensure that the trains move around on schedule and without stoppages – even in adverse weather conditions. With the...

Encoders for mobile machinery: the Turck mini holds tight

Automation in vehicle construction is like a rally course littered with obstacles – mobile applications place much higher demands on automation components than traditional industrial applications. With the compact,...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Accident prevention: it pays to play safe

Whether driverless or not, vehicles pose a hidden accident risk as soon as they are in motion. Increasing levels of automation also elevate this risk. Modern safety technology provided...

Capable of withstanding the most onerous demands: the new Li-Q25L linear position sensors from Turck

In some industrial environments, conditions can be harsh and unforgiving – vibrations, moisture and dirt interfere with the systems, putting the resistance of their components to the test. The...

Parker Viking Xtreme: the valve range with crossover qualifications

Parker Viking Xtreme: The valve range with crossover qualifications Stringent requirement criteria apply to pneumatic valves used in vehicle construction. Approval is only granted to products that reliably perform under...

Ultra-small and ultra-precise: the PBG linear guide from Samick

If the available space in laboratory devices is limited, this restricts the possibilities when assessing components. Regardless of the design, huge demands are placed on precision, especially in the...