Home > Pneumatics > Parker Viking Xtreme: the valve range with crossover qualifications

Parker Viking Xtreme: the valve range with crossover qualifications

Parker Viking Xtreme: The valve range with crossover qualifications

Stringent requirement criteria apply to pneumatic valves used in vehicle construction. Approval is only granted to products that reliably perform under extreme stress, satisfy strict safety regulations and can be fitted easily in confined engine compartments and gear housings, as well as in supply systems.

The name speaks for itself

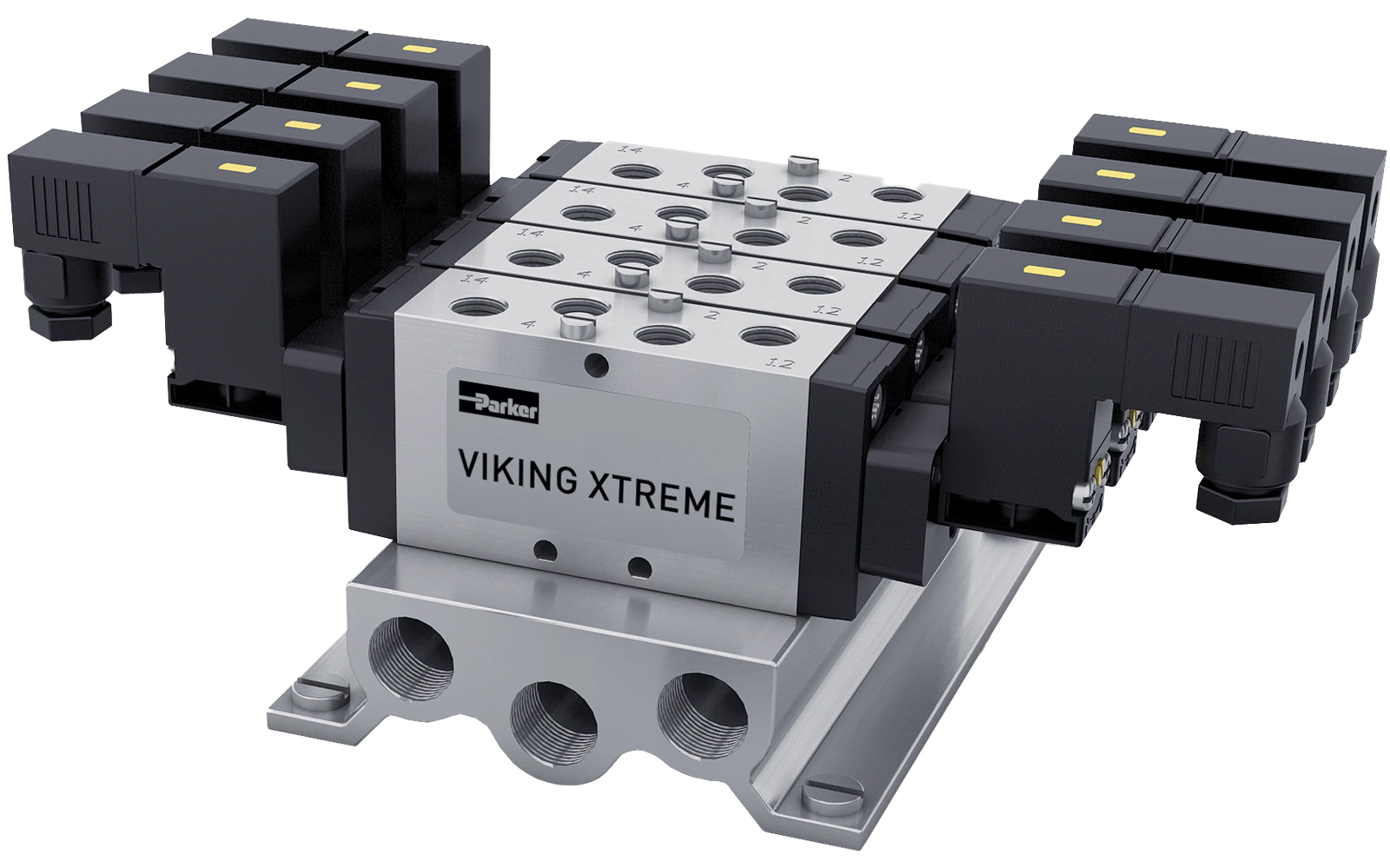

The valves in Parker’s Viking Xtreme range more than live up to their name. They have been specially developed for use under challenging general conditions and their sturdy construction, performance and versatility are impressive. The performance of these valves during aggressive salt spray tests and rigorous vibration testing has proven that they can cope with any situation. They come equipped with suitable solenoid valves and can be used in temperatures ranging from 40 to +60°C.

Sturdy, resilient construction

Dirt and corrosion pose no problem to Parker’s Viking Xtreme valves. The valves are manufactured from anodised aluminium and have a smooth surface with no depressions in which dirt can accumulate. The cover screws are made from stainless steel, which prevents weak points from developing over time. In the event of a power failure, the valves can be manually controlled via a locking or freely movable manual override.

Parker’s Viking Xtreme range of valves fully meets the requirements laid down by the Machinery Directive as per the standard specification sheets EN292-2 and EN983, which excludes liability risks. These extremely resilient products require intermittent maintenance, as is the case for any moving parts. That is why spare-part kits are available.

NAMUR interface for direct assembly on process valves

Anything that can perform under extreme conditions is all the more likely to be suitable for further applications. Applications in the process industry, for instance: Viking Xtreme is the right choice in this industry whenever a rotary drive or process valve needs to be controlled. The NAMUR interface enables the Viking Xtreme valve to be assembled directly onto the process valve.

Bachofen has been collaborating with Parker for many years now and shares Parker’s attitude on which development of the Viking Xtreme valve family is based, namely that “the greater the challenge, the greater the motivation to find the best possible solution for the user”.

Discover more components in vehicle construction

Areas of application

-

Vehicle construction and mechanical engineering

-

Construction of special-purpose vehicles for specific areas of application

-

Railway vehicle and track construction

-

Process industry

A robust portfolio of impressive benefits

-

Reduced downtime of machinery and plant

-

Increased productivity, which translates into greater profitability

-

Cost savings as a result of longevity and resilience

-

Rapid amortisation of costs

-

Suitable for pressures up to 12 or 16 bar, depending on connection size.

-

Compressed air in accordance with ISO 8573-1, class 3.4.3

Other focus topics in the area of vehicles

Wireless vehicle identification: miniature guardians

Installing sensors for vehicle identification doesn’t have to mean digging trenches and laying cabling. Banner’s wireless alarms are smaller than a hockey puck, can be sunk into the floor...

Guard duty on the ramp: BANNER vehicle detection

Open gates are somewhat inviting. Unfortunately that is also the case for unauthorised people. Previously it was commonplace to employ gatekeepers who kept an eye on the comings and...

Up to the harsh conditions of the road: stainless steel couplings from Parker

The pneumatic and hydraulic systems in public transport vehicles are exposed to particularly harsh conditions, as are the lines and couplings that play a central role in these systems....

Specially designed for work machines: the new Turck pressure transmitter PT1100/2100

The insides of work machines are exposed to harsh operating, ambient and weather conditions. Components such as pressure sensors are subject to requirements that far exceed those of applications...

Parker Viking Xtreme: the valve range with crossover qualifications

Parker Viking Xtreme: The valve range with crossover qualifications Stringent requirement criteria apply to pneumatic valves used in vehicle construction. Approval is only granted to products that reliably perform under...

No more last-minute door panic: the new non-touch system from Mayser

The doorways of buses, trams and trains can be hazardous for public transport passengers. Incidents involving automatic doors can cause serious injuries and damage the reputation of transport companies....

Mayser safety technology: combatting last minute panic in passenger traffic

Public transport is facing constant increases in acceleration, congestion and hustle and bustle. Especially at rush hour. And the risk of accidents is therefore also increasing for passengers. With...

Don’t get bent out of shape: supreme heavy-duty telescopic slides

Every composite system is only as good as its weakest part. This old truth applies in particular to the operation of commercial and railway vehicles. For there is barely...

No uncertainty on the rails: Rectus quick-release couplings

When operating railways, each individual component must be reliable to ensure that the trains move around on schedule and without stoppages – even in adverse weather conditions. With the...

Hot tip for pneumatic systems: non-flammable PA tubing from Parker

Standard products are not suitable for many functions in the maintenance of public transport rail and road vehicles. One important consideration, for example, is the prevention of overheating. This...

High load capacity, better value: the 7619 Jumbo telescopic slide from Thomas Regout

When purchasing mechanical components, it is important to seek out the best possible function, within the limits of what you need, while spending as little as possible. You need...

Encoders for mobile machinery: the Turck mini holds tight

Automation in vehicle construction is like a rally course littered with obstacles – mobile applications place much higher demands on automation components than traditional industrial applications. With the compact,...

Accident prevention: it pays to play safe

Whether driverless or not, vehicles pose a hidden accident risk as soon as they are in motion. Increasing levels of automation also elevate this risk. Modern safety technology provided...

A shining example of personal comfort: DUOmetric light curtain systems

For public transport companies, passenger comfort has top priority. A critical factor for this is the boarding and exit area with automatic doors. Despite safety contact strips, passenger comfort...