Home > Medical technology > Easy rider in a compact design: miniature RSX linear guide from THK

Easy rider in a compact design: Miniature RSX linear guide from THK

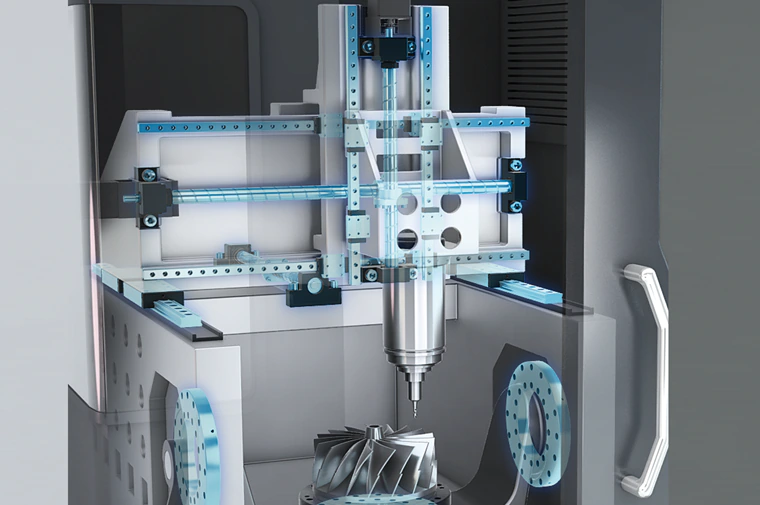

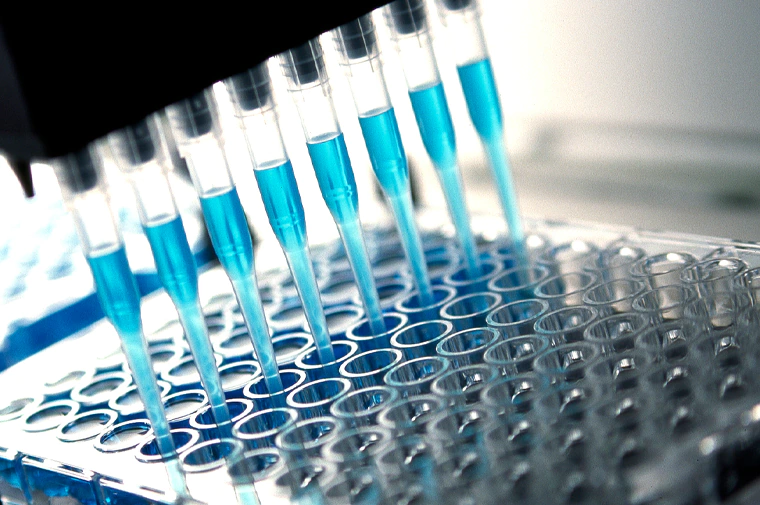

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The RSX mini linear guide from the leading provider of linear motion technology, THK, is proof that good things do come in small packages.

In mechanical engineering, space is a scarce commodity. Compact designs are on the advance, but this must not be at the expense of performance. Quite the opposite – consumers and users are not willing to accept compromises in terms of quality, precision or reliability. Innovative manufacturers of machine components, such as THK, are showing us the way out of this dilemma. With its new RSX miniature linear guide, our globally renowned technology partner has skilfully mastered the balancing act between compact design and excellent product properties.

Best-in-class anti-friction properties

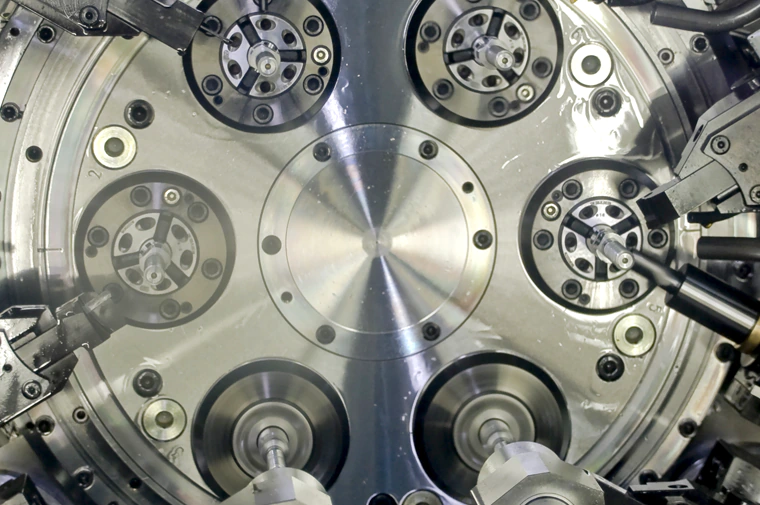

Thanks to an optimised circulation structure, the latest development in the THK portfolio offers the smoothest movement in the class of miniature guides: The guide carriage of the RSX slides much more smoothly than that of conventional linear guides. The tracks – which are ground with high precision – between the guide rail and the guide carriage support the easy running of the balls. Its characteristic design features include the end plates integrated into the guide carriage for the ball circulation and a ball retaining wire. This keeps the balls away from the rail when the carriage is removed, which also greatly facilitates assembly.

Small dimensions – high load capacity

Unlike other models, the RSX miniature linear guide has only two tracks rather than four, and a small section height. This means that it fits everywhere where space is at a premium. Yet this has hardly any effect on its load capacity: despite its small dimensions, the RSX can absorb loads from all directions and can even be used individually for moment loads. Various types of carriages allow for a broad range of applications.

The RSX miniature linear guide is suitable for use in cleanrooms and can be adapted in various ways to comply with the cleanroom class required for the application, from ISO 1 to ISO 9. The guide carriage, guide rail and balls are made of highly corrosion-resistant stainless steel. A special material technology with heat treatment guarantees reliable operation up to temperatures of 150°C.

Bachofen’s made-to-measure solutions

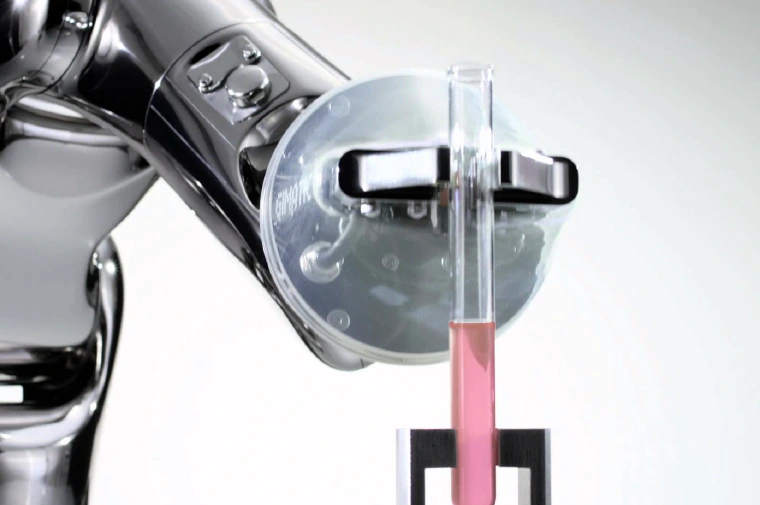

When it comes to adaptability, this tiny linear guide is hard to beat: the surface treatment, metal rotating parts, block length, stroke type and more can be adapted to meet the customer’s specifications. This is where Bachofen’s advice can help you. Our motion technology specialists will assist you with the configuration and make sure you get exactly what you need: a made-to-measure solution.

Discover more THK-products

Areas of application

-

Medical technology

-

Electronics industry

-

Watch industry

-

Precision engineering

Good things come in small packages

-

Ultra-compact

-

Extreme precision and rigidity

-

Available in various sizes and configurations

-

Operating temperature up to +150°C

-

Suitable for cleanrooms

Downloads

Other focus topics in the area of medical technology

Ultra-small and ultra-precise: the PBG linear guide from Samick

If the available space in laboratory devices is limited, this restricts the possibilities when assessing components. Regardless of the design, huge demands are placed on precision, especially in the...

Tiny but mighty: the new HRG miniature roller guide from THK

A linear guide should take up minimal space but also deliver maximum performance. This contradiction inevitably leads to compromises when evaluating the options. But this is now a thing...

Sprinter in ISO Class 3: CSKR cleanroom actuators from THK

Avoiding particles when automating clean room processes is a top priority. With moving machine parts in particular, this key requirement is not that easy to meet since friction causes...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

On the move at high speed: the new BSM ball screw from THK

When speed is required, conventional ball screws quickly reach their limits. Traditional types have a DN value of between 60,000 and 120,000. THK’s new BSM ball screw exceeds these...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Continuous running systems: mini-format linear guidance systems

The requirement profile for moving parts in medical devices and systems for medical technical applications is dynamic: linear guidance systems must function for years without maintenance and without showing...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Don’t get bent out of shape: supreme heavy-duty telescopic slides

Every composite system is only as good as its weakest part. This old truth applies in particular to the operation of commercial and railway vehicles. For there is barely...

Ideal for the lab: PFA fluoropolyer tubing from Parker

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

High load capacity, better value: the 7619 Jumbo telescopic slide from Thomas Regout

When purchasing mechanical components, it is important to seek out the best possible function, within the limits of what you need, while spending as little as possible. You need...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Flexible arc guides: practice on the right track

Machine manufacturers are required to fulfil increasingly specialised requirements. Yet they are also under pressure in terms of costs. The solution to this dilemma is multifunctional standard components that...

Effective protection for lab personnel: the new safety sensors from Turck

The extensive automation of analysis and processing in laboratories leads to increased risks for lab employees. There is a particularly high risk of injury in the case of open...

Easy rider in a compact design: miniature RSX linear guide from THK

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The...

Clean work: robotics in the clean room

The best employees in production under clean room conditions are those who remain outside, as double door designs are complex and impede the freedom of movement of the staff....

Capable of withstanding the most onerous demands: the new Li-Q25L linear position sensors from Turck

In some industrial environments, conditions can be harsh and unforgiving – vibrations, moisture and dirt interfere with the systems, putting the resistance of their components to the test. The...

Assembly in place of an individual product: cost efficiency through outsourcing

The enormous cost pressure and increasingly tougher conditions of competition in the medical sector are also forcing machine and plant builders to rethink their supply chain and to streamline...