Home > Fluid connectors > Meets the standards and remains ecological: parker legris liquifit

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that come into direct contact with products. Parker Legrisʼs Liquifit Connection Systems, machine builders and plant operators are off the hook, including in ecological terms.

Production companies that are employed in the food, beverages, pharmaceutical or cosmetics sectors enjoy the special attention of the regulators. In addition to the general safety regulations, specific requirements apply for their machines and systems relating to clean production, cleaning and disinfection.

The Machinery Directive as the measure of all things

The Machinery Directive specifies the guiding principles and its most recent update sets out the production goods for pharmaceutical and cosmetic products in practically the same steps as those for the food industry. Harmful health risks for consumers must be completely ruled out.

In keeping with the regulators

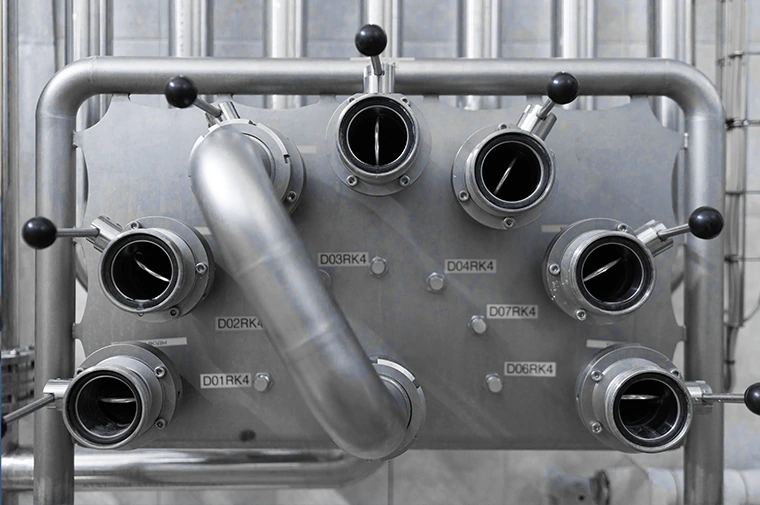

In the field of fluid transport, Parker Legris guarantees that the strict regulator stipulations do not cause upset for machine builders and plant operators. The Liquifit product family includes a wide range of reliable and compact connections for all applications in the fluid field. The fittings, made from polymer, with metal adapters and parallel threads, are made of either 316L grade stainless steel or FDA-compliant nickel-plated brass, depending on the type. They boast excellent mechanical strength and robustness, combined with an ideal seal. The unique design is configured according to ecological principles, with which Parker contributes to protecting the environment, thanks to the comparatively small carbon footprint of its products.

Manufacturing using the Ecodesign process

The Liquifit range fittings fulfil NSF 51 or NSF 61 criteria respectively, depending on the type. The range of components manufactured from biological polymers also complies with the requirements of the KTW and W270 guidelines. They are guaranteed to be free of Bisphenol A and phthalates and are therefore ideally suited for the transport of water, beverages and industrial fluids.

Bachofen manages the full Liquifit range from Parker Legris and ensures that everything on the economical side is compliant: with project-oriented advice, technical support and short delivery times.

Downloads

Shop now LIQUIfit

Discover more products from Parker

Areas of application

-

Food industry

-

Medical technology

-

Water purification

-

Inert gas transport

-

Cooling systems

-

Drinks machines

-

Water dispensers

Progress through performance

-

Ergonomic, visually attractive design

-

Most compact fitting for liquid food on the market

-

Easy-to-clean design without dead space

-

Lightning-fast fitting and removal of the hose

-

Also for use with pre-prepared metal tubing

-

Retaining system with clamping ring prevents a “pumping effect”

-

Ecological design: choice of materials, manufacturing process, weight

Other focus topics in the area of fluid connectors, food, medical technology, and pharma

The safe alternative to the Zener barrier: ATEX-compatible IMX12-SG strain gauge evaluation device from Turck

Strain gauge evaluation devices for use in ATEX zones are a rarity. The divide between ATEX and non-ATEX areas is particularly critical. With the IMX12-SG interface, Turck has unveiled...

Now remotely controlled by IO-Link: Positioner 8049 from Schubert & Salzer

In plant operation, personnel deployments on site may be time-consuming and awkward in some situations. This also applies to adjusting and maintaining control valves, which are often difficult to...

Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable...

Universal I/O: Seamlessly from Ex to non-Ex

Decentralised I/O systems are becoming increasingly widespread across the chemicals and pharmaceuticals industry. Data transfer from explosion-risk process areas, high availability and accurate diagnosis and identification of fault sources...

Hygienic design: consistent down to the smallest connector

When constructing plants for industrial food production, every single detail needs to be considered when it comes to hygiene, and connection technology is no exception. Turck provides two product...

Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the...

Avoiding disaster: the TN-R42TC-EX RFID write/read head from Turck

Faulty connections in the hose station can become a nightmare for pharmaceutical, chemical and food producers. Reliable monitoring of hose connections, ideally with RFID, is clearly a necessity. The...

Hot tip for pneumatic systems: non-flammable PA tubing from Parker

Standard products are not suitable for many functions in the maintenance of public transport rail and road vehicles. One important consideration, for example, is the prevention of overheating. This...

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes...

Sustainability thanks to precision and control: Conductivity meter from Anderson-Negele

Saving potential through process monitoring - One incorrectly switched valve in the filling plant and it's over: The end product is placed in the wrong container and operation has...