Sustainability thanks to precision and control: Conductivity meter from Anderson-Negele

Saving potential through process monitoring

One incorrectly switched valve in the filling plant and it’s over: The end product is placed in the wrong container and operation has to be brought to a halt. This horror scenario can be avoided with the ILM series conductivity meter.

Savings potential in CIP* processes

In the CIP cleaning phase, the exact dosage of acid or alkaline is very important for efficient cleaning. Precise measurement is essential to save cleaning agents, water and energy.

Linking process reliability and energy efficiency

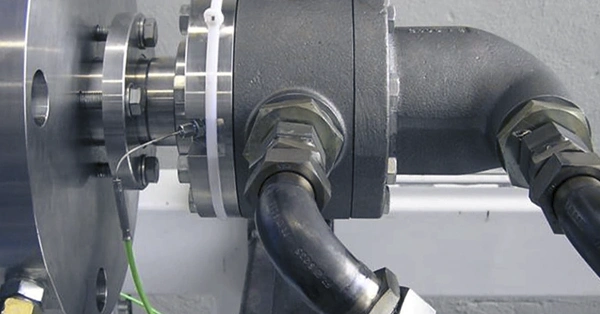

In both cases, the IML-4 inductive conductivity meter from Anderson-Negele is an impressive solution for in-line, hygienic monitoring and controlling of processes with the highest precision. Based on the principle of inductive conductivity measurement, the sensor displays the current conductivity readings, which can be compared with the expected values. This prevents products from being filled into the wrong containers. For applications in CIP processes, the IML-4 conductivity meter supports the efficient use of cleaning agents through economical dosing.

Fast, accurate and communicative

This sensor from Bachofen technology partner Anderson-Negele is characterised by a fast, four-second response time, high measuring accuracy and the integrated IO-Link interface. Benefit from Bachofen’s process knowledge to optimise your plant’s energy efficiency and increase operational reliability.

*CIP = Clean-in-Place

Discover more conductivity sensors

Areas of application

-

A wide range of applications in the food and beverage industry

-

Product differentiation

-

Phase separation

-

CIP detergent dosing

Everything under control

-

Choose between compact and remote versions

-

Output 4–20 mA and IO-Link for configuration and evaluation

-

Suitable for all commercially available connections, such as dairy pipe, Varivent, CleanAdapt etc.

-

Configurable according to the application: full version with all options or slim, cost-effective version

Other focus topics in the area of chemical, pharma and food industry

Modular alarm design in variations: K100 Pro Beacon hazard indicator from Banner

It is in the nature of industrial production that it is associated with safety risks. Where hazardous substances are involved in production and processing plants, potential risks cannot be...

Reliable means safe: ATEX-certified rotary joints

Due to the friction they create, rotating connections form one of the hazard sources in explosion-risk areas, such as in the chemicals and pharmaceuticals industry. The pre-conditions in gaseous...

Transporting liquids: seeking the eco-friendly solution

The strict hygiene requirements in the industrial food production sector applies across the entire production chain. A key area of interest right now is also how to minimise your...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Fast to market and still Ex compliant: decentralised automation with Turck

Time to market is a key factor for operating successfully in highly competitive markets. Barely is development of a new product over and already it needs to be available...

Automated climate monitoring in the warehouse: Condition monitoring with Turck and Banner

When storing sensitive products, continuous temperature and humidity control is essential to prevent product losses. However, doing this manually requires a lot of effort. A complete condition monitoring solution...

Integrated inline in the process: moisture measurement with Liebherr sensors

Traditional methods of moisture measurement may be justified in non-automated processes. However, these are rarely suited to use on production lines. Liebherr moisture sensors are very different. These function...

Now remotely controlled by IO-Link: Positioner 8049 from Schubert & Salzer

In plant operation, personnel deployments on site may be time-consuming and awkward in some situations. This also applies to adjusting and maintaining control valves, which are often difficult to...

Hygienic valve technology: in accordance with all norms and standards

Valve technology ranks among the particularly demanding aspects for industrial food production plant. Valves usually have many standards and norms to fulfil in addition to the high, purely functional,...