Home > Automation technology > Universal I/O: Seamlessly from Ex to non-Ex

Universal I/O: Seamlessly from Ex to non-Ex

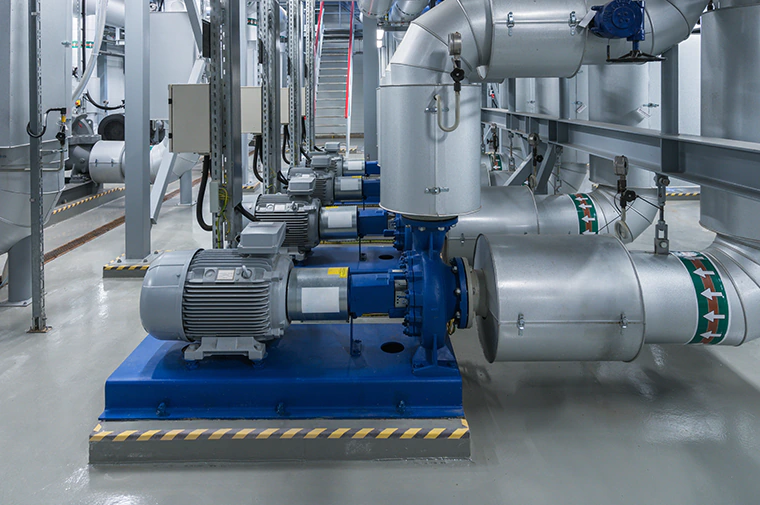

Decentralised I/O systems are becoming increasingly widespread across the chemicals and pharmaceuticals industry. Data transfer from explosion-risk process areas, high availability and accurate diagnosis and identification of fault sources are important for the sector.

Many years of industry experience make the difference

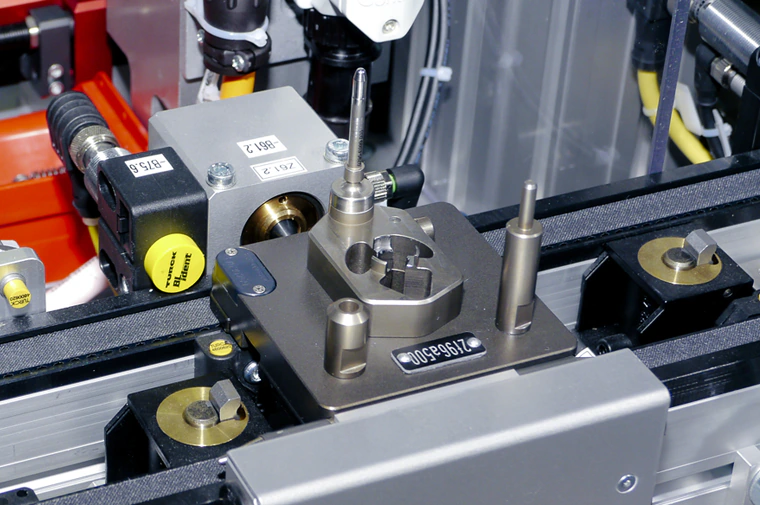

TurckIndustry-fit I/O systems provide user assurance thanks to high functionality and simple operation, and these are just two of the numerous strengths of the excom® I/O system from Turck. It can be installed in zones 1 and 2 and in the non-Ex area and be connected to the control system. The field circuits are permitted up to and including Zone 0.

The universal I/O system from automation specialists Turck incorporates Bachofen’s automation expertise. The benefits of this for system operators are personal contact and one-to-one discussion. Two specialists, one point of contact for you.

A flexible concept and redundancy for high availability

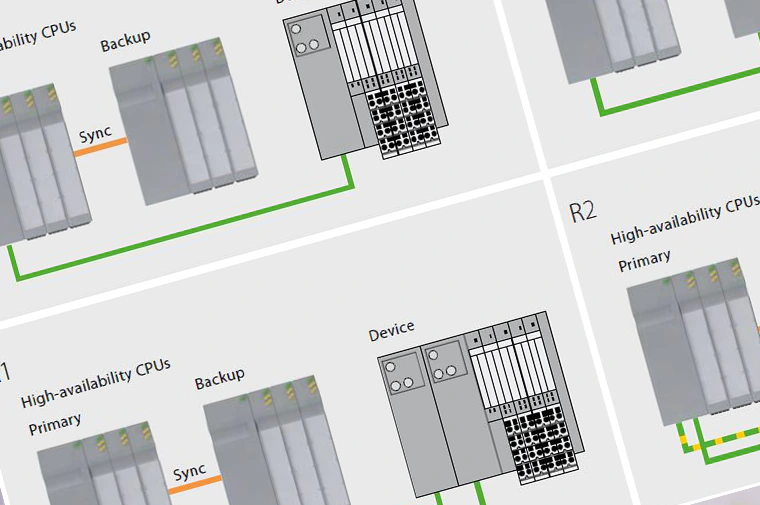

The components of the excom® I/O system are optimised for each usage zone. The standardised concept for configuration and parametrisation of the periphery and field instruments reduces cabling costs while saving time and engineering expense. Thanks to the module MT08, MT16 and MT24 module racks, excom® is flexible enough to fit any application. Every module rack can be operated with two network components and two gateways, resulting in intelligent redundancy for high availability.

«Make use of Bachofen’s I/O system expertise for success in your automation solution.»

Roland Fuchs, Product Manager Bachofen AG

Downloads

- Lösungen für die Chemieindustrie

You can find more remote I/O systems in the online shop

Discover more products from Turck

Areas of application

-

Fermenter control

-

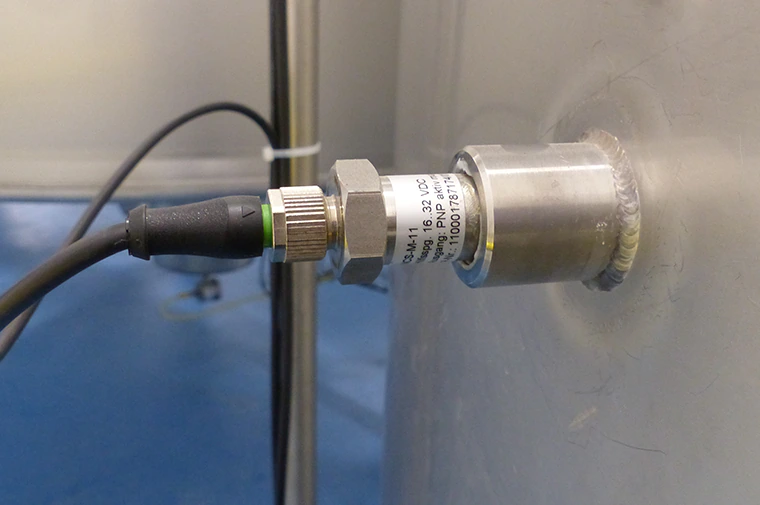

For the identification of mobile containers and for identifying hose-lines at hose-line interchanges

-

For the monitoring of temperature, indoor humidity and incorrectly closed doors

The benefits and services: More than just 'standard'

-

A single modular system for all areas (non-Ex, Zone 1, Zone 2)

-

Extremely high channel density thanks to compact construction

-

Online configuration and parametrisation of all parameters while in operation

-

DTM-based operation of the periphery and field instruments

-

Full redundancy for power supply and gateways

Other focus topics in the area of chemical, pharma and control technology

Lights that speak: the new WLS27 pro-lights from Banner

When monitoring machinery, processes, actions or user behaviour, speed and clarity are paramount. The most efficient medium for these purposes is light. With its new WLS27 Pro-lights that are...

Wireless vehicle identification: miniature guardians

Installing sensors for vehicle identification doesn’t have to mean digging trenches and laying cabling. Banner’s wireless alarms are smaller than a hockey puck, can be sunk into the floor...

Visionary capabilities: predictive maintenance from Banner

Once machines start to vibrate, production can stall or come to a complete standstill and the costs resulting from downtime can take on astronomical proportions. Predictive maintenance using a...

Uniformity in diversity: the Turck family of fluid sensors

The world of fluid sensors is bewilderingly wide and diverse. There are countless types, features and designs that make it hard to choose the most suitable component for the...

Out into the field: CODESYS-3 controller TBEN-Lx-PLC from Turck

Some machine manufacturers are still hesitant when it comes to relocating controllers into the field, even though the benefits of decentralization are very clear. The CODESYS-3 controller TBEN-Lx-PLC from...

Turck Ethernet Gateway for excom: make way for ethernet in the ex zone

The use of Ethernet in EX zones within the process industry was previously impossible due to safety issues. But now Turck has made a breakthrough with its GEN-3G Ethernet...

One IP address for an entire sub-network: all thanks to beep from Turck

With the TBEN-S, TBEN-L and FEN20 fieldbus modules, Turck is opening up new possibilities for machine and plant manufacturers. Each device on a network can be reached via an...

Sprinter in ISO Class 3: CSKR cleanroom actuators from THK

Avoiding particles when automating clean room processes is a top priority. With moving machine parts in particular, this key requirement is not that easy to meet since friction causes...

So nothing flares up in production: TSM temperature sensor from Anderson Negele

Process reliability is the top priority in the food and pharmaceutical industries. Disruptions affect producers’ ability to supply and can damage their reputation. Much depends on the reliability and...

Smart and alert: the COBOTTA compact robot

Due to space limitations, the use of robots often proves difficult. Programming is also a critical factor since, depending on the manufacturer, it can be a very lengthy process....

Shining a light on assembly processes: the pick-to-light solution from Banner

Making mistakes is human. Even the most reliable employee can make mistakes during commissioning and those mistakes can cause the installation process to stall, affecting productivity. Using a Pick-to-Light...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Reliable means safe: ATEX-certified rotary joints

Due to the friction they create, rotating connections form one of the hazard sources in explosion-risk areas, such as in the chemicals and pharmaceuticals industry. The pre-conditions in gaseous...

Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet has established itself as the communications standard for factory automation. Vehicle manufacturers and suppliers have been demonstrating the practical suitability of industrial Ethernet-based data exchange for a number...

Product identification: no cakewalk in the food industry

An identification system’s true value becomes most apparent when it is subjected to demanding general conditions. These are particularly challenging in the food industry. Due to its resistant properties,...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Prime example for industry 4.0: the machine thinks along with you

Is the tool suitable for the next processing step and when is the next service due? This information is crucial for ensuring that manufacturing runs smoothly with no long...

Prevention is better: monitoring using the Edge Gateway from Turck

Many operating faults in machinery and systems go undetected until the process itself starts to falter. If the operation was permanently monitored, any functional faults that were about to...

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Out of the control box: towards decentralised concepts

In the world of Industry 4.0, modularity is gaining increasing importance in the manufacture of machinery and systems. This development is also promoting the decentralisation of I/Os and control...

Optical sensor: green light for LED

Machine are carrying out increasingly complex functions and are increasingly networked, reflecting Industry 4.0. This also results in higher demands on the optical sensors. The future lies in LED...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

No risks in the control cabinet: the IM18-CCM control cabinet motor from Turck

Unplanned machine and system downtimes are a costly irritation for producers in the food, beverage and pharmaceutical industries. The cause can often be found in the control cabinet, which...

Moving securely ahead into the future of cloud computing: data transfer using the edge gateway from Turck

Industry 4.0 is entirely dominated by the cloud, however the massive potential offered by these types of technology is still far from being exhausted. The key when it comes...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Meets the standards and remains ecological: Parker Legris Liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Measuring on the tank instead of in the tank: precision load cells from Anderson-Negele

Measuring content in process containers with complex shapes or in horizontal positions is not straightforward. Depending on the tank design, using conventional sensors for fill level measurements can lead...

Linking factory and building automation: Intesis gateways from HMS Networks

There used to be a deep divide between information technology and operation technology. This was also a problem for building services, where automation is progressing in leaps and bounds....

Keeping an eye on the tank: L3 pressure transmitter from Anderson-Negele

If you cannot see what is going on inside tanks in food or pharmaceutical production, the processes are almost impossible to control. To ensure process reliability, the tank contents...

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as...