Home > Automation technology > Product identification: no cakewalk in the food industry

Product identification: no cakewalk in the food industry

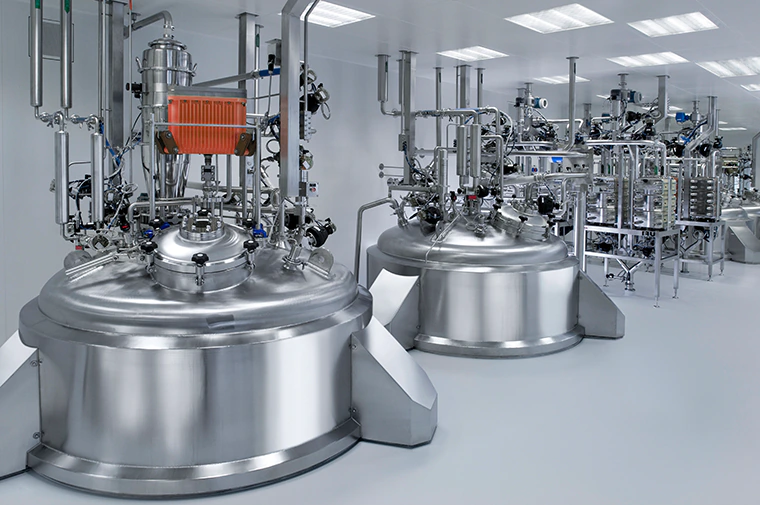

An identification system’s true value becomes most apparent when it is subjected to demanding general conditions. These are particularly challenging in the food industry. Due to its resistant properties, Turck’s modular BL ident® RFID system will whet the appetite of prudent plant constructors.

There is no shortage of challenges in plant construction for industrial food production. Constructors must delve into matters relating to hygiene, traceability, food safety and automated documentation and deal with these, all while keeping a watchful eye on productivity and the process control’s efficiency.

Cleaning as a test

The effectiveness of cleaning the plants, which is essential for the food sector, is an issue in its own right. The fact that cleaning must be carried out periodically, often at short intervals, needs to be taken into consideration. This is the reason why highly aggressive detergents are sometimes used. A plant and each of its individual components must also be able to tolerate high temperatures and pressures during the cleaning process.

Coping with the most adverse environmental influences

Under these demanding conditions, the modular BL ident® RFID system from the automation specialist Turck can fully demonstrate its strengths compared to optical identification technologies, such as QR code or barcode recognition. Read and write functions can be carried out without direct visual contact, for example. The RFID data carriers are particularly resistant to intensive cleaning methods as well as other environmental influences such as dirt, the formation of ice or dew, ambient light or minor mechanical damage.

RFID — the predominant technology in the food sector

Turck’s modular BL ident® RFID system can handle larger quantities of data without being connected to a database better than other technologies while enabling a variety of data carriers to be simultaneously recognised. These have a compact design and do not take up much space in the plant. The system enables batches to be changed over more quickly or reliably controls the mixed and flexible production of various products. As a result, it also makes a significant contribution to increasing process efficiency.

Bachofen will identify your specific requirements before implementing BL ident®. Successful deployment of the system is ensured through the competent advice and support provided during its construction.

Downloads

- Solutions for the food industry

- Flyer, Blident modular RFID system

- RFID solutions for optimized chocolate production

- Compact RFID modules with I/O

- Catalog, Blident-modular RFID system

Shop now BL ident® RFID system

Discover more products from Turck

Easily identifiable advantages

-

meat hooks

-

test bottles

-

goods carriers in autoclaves

-

plastic crates in workplaces and for intralogistics

-

pallets

-

cheese moulds

-

machine parts

-

drying racks

-

chocolate moulds in the production line and the washing machine

-

machine operators

-

transport trays

-

stainless steel transportation containers

-

temporary storage racks

Areas of application

-

Ideal solution for applications in the harsh food-industry environment

-

Resistant to any type of environmental influence

-

Protection classes IP68 and IP69K

-

Rapid and reliable identification, which results in increased quality and efficiency

Other focus topics in the area of food and control technology

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

The safe alternative to the Zener barrier: ATEX-compatible IMX12-SG strain gauge evaluation device from Turck

Strain gauge evaluation devices for use in ATEX zones are a rarity. The divide between ATEX and non-ATEX areas is particularly critical. With the IMX12-SG interface, Turck has unveiled...

Dry break and no dead spaces: the 200 Series coupling system from Parker

In hygiene-sensitive environments, liquid cooling is a proven means of preventing processes from overheating. However, line connections must be totally leak-proof, especially when aggressive media are involved. With Parker‘s...

Prevention is better: monitoring using the Edge Gateway from Turck

Many operating faults in machinery and systems go undetected until the process itself starts to falter. If the operation was permanently monitored, any functional faults that were about to...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Reliable final inspections: eagle-eyed error detection

Packaging and labelling processes used in the food industry are mainly geared towards processing materials quickly. Final inspections take even greater precedence. These must be performed without any hitch...

Fast to market and still Ex compliant: decentralised automation with Turck

Time to market is a key factor for operating successfully in highly competitive markets. Barely is development of a new product over and already it needs to be available...

Wireless vehicle identification: miniature guardians

Installing sensors for vehicle identification doesn’t have to mean digging trenches and laying cabling. Banner’s wireless alarms are smaller than a hockey puck, can be sunk into the floor...

Getting ahead in the world of RFID: the new UHF RFID read/write head from Turck

RFID-based applications used in materials handling and in goods logistics are many and various. Until now, it was a case of using the right reader for the right application,...

Sprinter in ISO Class 3: CSKR cleanroom actuators from THK

Avoiding particles when automating clean room processes is a top priority. With moving machine parts in particular, this key requirement is not that easy to meet since friction causes...