So users aren't left out in the rain: Moisture sensors from Liebherr

The moisture content of bulk materials is measured for more than just quality assurance. It is also relevant to the energy efficiency of processing operations. With the precise humidity sensors from Liebherr, humidity remains under constant control. For more quality and sustainability.

Humidity is one of the most important quality parameters for the industrial processing of bulk materials. But today, more than ever, plant operators are required to keep an eye on the sustainability of processes. This is not simply a matter of environmental sustainability, but also money: No company can afford to waste resources, because excessive consumption puts pressure on already tightly calculated margins. The use of sophisticated measurement technology in automated processes is essential for cost- and energy-efficient plant operation.

Moisture measurement with triple benefits

Humidity measurement plays a key role in numerous applications, such as in the food industry. Firstly, moisture monitoring during drying can save an enormous amount of energy and minimise the risk of plant downtime due to jamming of downstream machines. Secondly, precise moisture measurement increases the quality of the product and keeps it consistently high by adhering to the predefined tolerances. This helps to reduce waste and rejected products. Thirdly, reliable humidity sensors are playing an increasingly important role in meeting ever more stringent environmental standards.

Liebherr for maximum precision

Liebherr humidity sensors have a high precision level of up to 0.05% – also thanks to temperature compensation. They are robustly built, durable and perform reliably and safely even in harsh environments. Easy installation and operation save time and effort.

Bachofen for convincing solutions

Up to 16 sensors can be connected to each evaluation unit in a system. If required, users can take advantage of the technical advice and process knowledge of Bachofen experts, leading to an all-round application-oriented solution.

Discover the humidity sensors from Liebherr

Areas of application

-

Pharmaceutical and chemical industries

-

Food industry

-

Paper/wood industry

-

General: moisture measurement of granules, powders and liquids

"Made in Germany" reliability

-

Precise and reproducible humidity measurement

-

Compact and extremely robust design

-

Exposed sensor surface made of zirconium oxide ceramic for optimum protection against wear

-

Measuring range 0 to 100% moisture content with an accuracy of up to 0.05%

Reference projects

Bühler AG

Process industry

Bühler AG

Process industry

Developing sustainable protein sources: Bühler Insect Technology

In the coming decades, the demand for protein for humans and animals will dramatically increase, but conventional protein sources are not environmentally friendly. Using insect protein plants, Bühler is taking another path.

“The insect industry is still in its infancy. That is why we rely on partners like Bachofen in developing these facilities; partners who don’t want to fob us off with standard products, but who are ready to put time, creativity and their heart and soul into a project.“

Nicolas Braun, Bühler AG, Business Development Manager Insect Technology- Developer

Other focus topics in the area of infrastructure, chemical, pharma and food industry

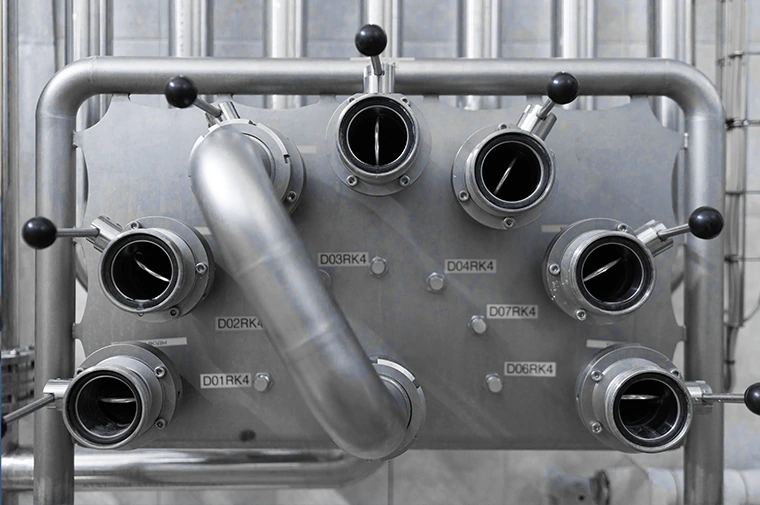

Transporting liquids: seeking the eco-friendly solution

The strict hygiene requirements in the industrial food production sector applies across the entire production chain. A key area of interest right now is also how to minimise your...

Modular alarm design in variations: K100 Pro Beacon hazard indicator from Banner

It is in the nature of industrial production that it is associated with safety risks. Where hazardous substances are involved in production and processing plants, potential risks cannot be...

Avoiding disaster: the TN-R42TC-EX RFID write/read head from Turck

Faulty connections in the hose station can become a nightmare for pharmaceutical, chemical and food producers. Reliable monitoring of hose connections, ideally with RFID, is clearly a necessity. The...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Not a drop too much, not a drop too little: FMQ flowmeter from Anderson-Negele

Poor control of flow in production equipment pipelines will affect process efficiency and incur costs. The more accurate the measurement, the safer the production process. The FMQ flowmeter from...

No risks in the control cabinet: the IM18-CCM control cabinet motor from Turck

Unplanned machine and system downtimes are a costly irritation for producers in the food, beverage and pharmaceutical industries. The cause can often be found in the control cabinet, which...

Keeping an eye on the tank: L3 pressure transmitter from Anderson-Negele

If you cannot see what is going on inside tanks in food or pharmaceutical production, the processes are almost impossible to control. To ensure process reliability, the tank contents...

Reliable final inspections: eagle-eyed error detection

Packaging and labelling processes used in the food industry are mainly geared towards processing materials quickly. Final inspections take even greater precedence. These must be performed without any hitch...

The safe alternative to the Zener barrier: ATEX-compatible IMX12-SG strain gauge evaluation device from Turck

Strain gauge evaluation devices for use in ATEX zones are a rarity. The divide between ATEX and non-ATEX areas is particularly critical. With the IMX12-SG interface, Turck has unveiled...

Hot and cold in alternation: a heat exchanger’s job

The principle of temperature transfer from one medium to another without direct contact between the media is used in an extremely diverse range of industrial processes. As such, the...