On the move at high speed: the new BSM ball screw from THK

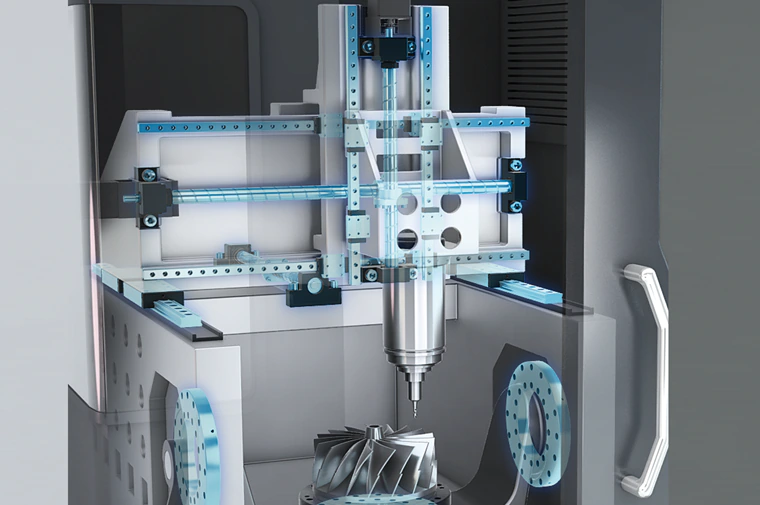

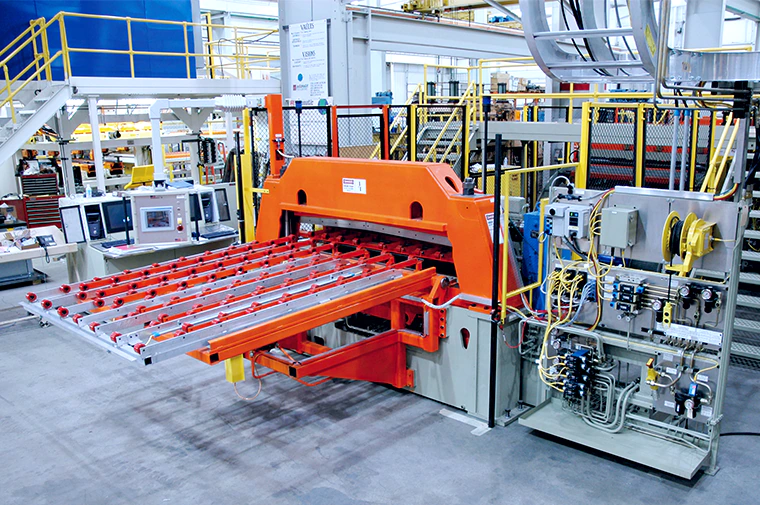

When speed is required, conventional ball screws quickly reach their limits. Traditional types have a DN value of between 60,000 and 120,000. THK’s new BSM ball screw exceeds these values by far with a record-breaking DN value of 170,000, which should be music to the ears of machine tool builders in particular.

Ball screws are inherently highly efficient and ideally suited for handling motion processes with high cycles. When they are used in machine tools, they cannot move fast enough. This is because, in industrial production, productivity is a critical competitive factor. While there is certainly an immense range of ball screws on the market, when it comes to speed, machine designers have to live with limits. But now there’s good news.

Previously unattainable load ratings and feed rates

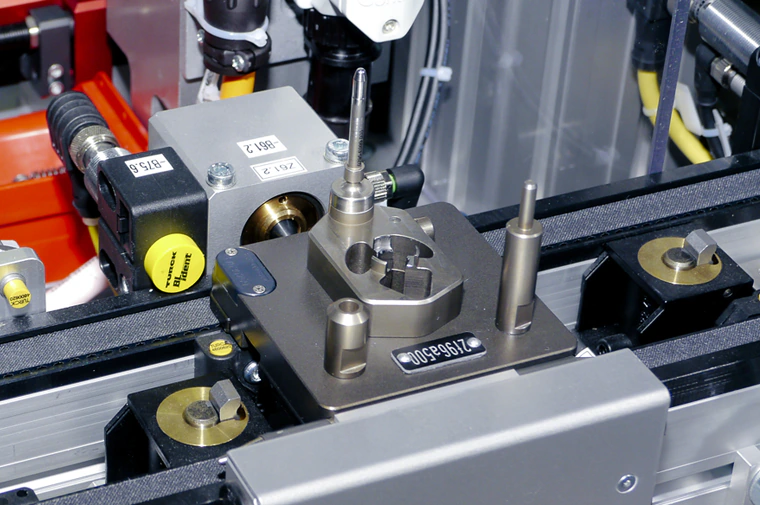

THK specialises in motion technology in the high-precision segment. It has taken ball screw development up a notch and is launching a new full-ball screw with particularly impressive high load ratings and feed speeds. Thanks to a recirculating ball system designed for high speeds, the new product achieves a DN value of 170,000. In conjunction with the large leads of the associated screw shaft, the new ball screw leaves conventional full-ball screws far behind in terms of speed.

Revised design of the groove profile and nut

Bachofen technology partner THK has also focused on the grooved profile and the single nut. A new design of the grooved profile increases the load ratings, and the slimmed-down and lengthened nut enables a more compact design of the connection construction. The nut also has higher rigidity because more ball recirculations are integrated. To protect the ball screw against contamination under rough operating conditions, the nuts can be provided with various seals and contact wipers. Furthermore, the relubrication intervals can be extended significantly with the QZ lubrication system.

The right solution for every application

At Bachofen, the complete range of high-speed THK BSM ball screws is available in the standard diameters of 40 – 63 with thread leads of 16 – 30 mm. Bachofen’s customer advisers are also on hand where required with detailed technical information, application expertise and all the support required to make machine manufacturers more successful.

Downloads

Discover more ball screws

Discover more products from THK

Areas of application

-

Machine tools

-

Mechanical engineering

Tailored to speed

-

High-speed ball screw for machine tools

-

High load ratings thanks to optimised design

-

High rigidity

-

More compact nut compared to standard ball screws

Autres thèmes de focalisation dans le domaine machines-outils, machines, installations et appareils

Lights that speak: the new WLS27 pro-lights from Banner

When monitoring machinery, processes, actions or user behaviour, speed and clarity are paramount. The most efficient medium for these purposes is light. With its new WLS27 Pro-lights that are...

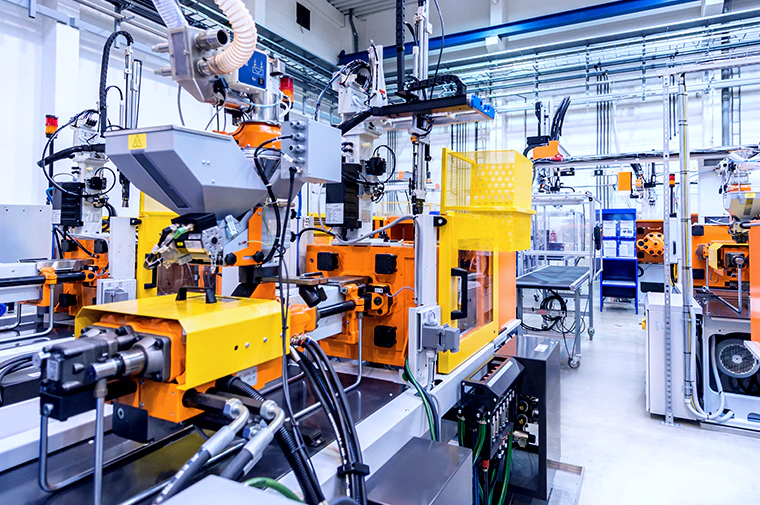

Out into the field: CODESYS-3 controller TBEN-Lx-PLC from Turck

Some machine manufacturers are still hesitant when it comes to relocating controllers into the field, even though the benefits of decentralization are very clear. The CODESYS-3 controller TBEN-Lx-PLC from...

One IP address for an entire sub-network: all thanks to beep from Turck

With the TBEN-S, TBEN-L and FEN20 fieldbus modules, Turck is opening up new possibilities for machine and plant manufacturers. Each device on a network can be reached via an...

Tiny but mighty: the new HRG miniature roller guide from THK

A linear guide should take up minimal space but also deliver maximum performance. This contradiction inevitably leads to compromises when evaluating the options. But this is now a thing...

Solutions and expertise to meet your needs: Bachofen Engineering

As a rule, manufacturers come under a lot of pressure in terms of time, costs and innovations. And on top of that, they are faced with consistently high customer...

Procurement made easy: Bachofen safety technology from a single source

There are many aspects to the safety of machines, plant and vehicles. However, designers and operators have more important things to do than be setting up an evaluation process...

Prime example for industry 4.0: the machine thinks along with you

Is the tool suitable for the next processing step and when is the next service due? This information is crucial for ensuring that manufacturing runs smoothly with no long...

Prevention is better: monitoring using the Edge Gateway from Turck

Many operating faults in machinery and systems go undetected until the process itself starts to falter. If the operation was permanently monitored, any functional faults that were about to...

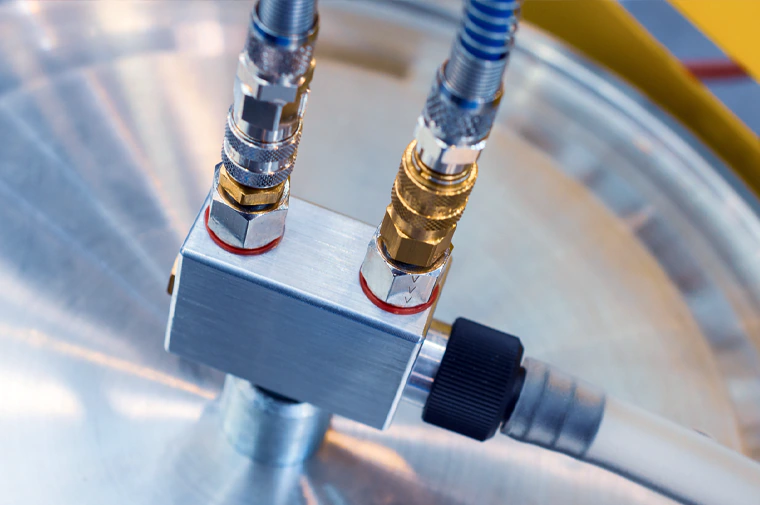

Diversity and quality combined: Parker Rectus connection technology

Need to disconnect fluid connections quickly, cleanly and without any tools? Then look no further than the Rectus couplings from Parker. Parker has the right coupling for every conceivable...

Out of the control box: towards decentralised concepts

In the world of Industry 4.0, modularity is gaining increasing importance in the manufacture of machinery and systems. This development is also promoting the decentralisation of I/Os and control...

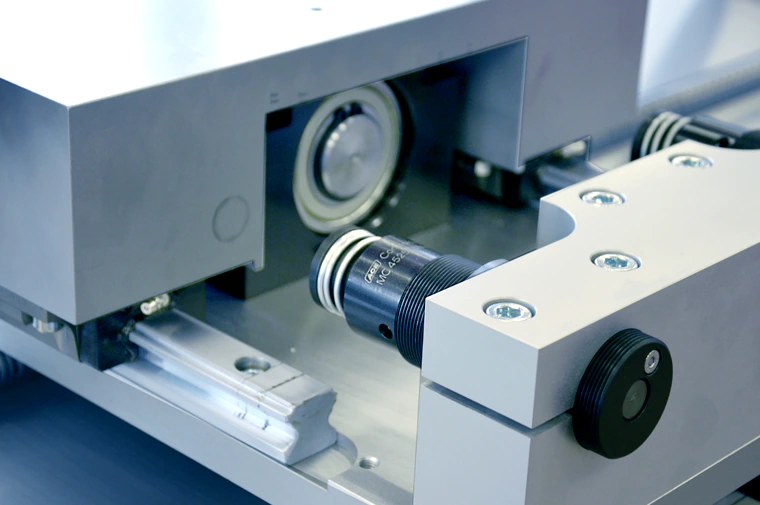

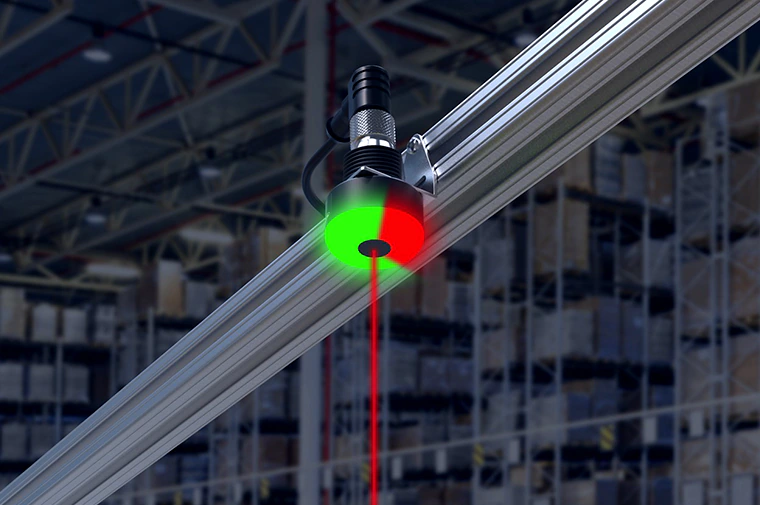

Optical sensor: green light for LED

Machine are carrying out increasingly complex functions and are increasingly networked, reflecting Industry 4.0. This also results in higher demands on the optical sensors. The future lies in LED...

On the move at high speed: the new BSM ball screw from THK

When speed is required, conventional ball screws quickly reach their limits. Traditional types have a DN value of between 60,000 and 120,000. THK’s new BSM ball screw exceeds these...

Eagle eyes in the compressed air network: flow sensors from EGE

Compressed air is expensive. One cubic meter can easily cost 10 to 20 Swiss centimes. Too much to waste. Flow sensors from EGE with IO Link display leakages immediately...

Modbus-compatible and networked: electric actuators from Valpes

The ability of measurement and control systems to communicate is of central importance to the safe operation of systems. Electric actuators from Valpes can be configured and controlled using...

Manpower: too good for repetition and routine

High-performance machine guarantee a high level of productivity thanks to efficient production. This is compromised if an operating person is required to load and unload the machine. DENSO robots...

Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the...

Interference-free wireless: say goodbye to interference

Wireless networking is a key element of Industry 4.0. It is, however, difficult to implement in industrial environments. Until now, interference and long distances have affected the wireless transfer...

Distance yourself from mediocrity: the Turck uprox® 3 factor 1 sensors

Inductive sensors, for applications in special machine engineering and other demanding fields, should ideally have high switching distances, be compact and form a key element for reliable machine and...

Hot tip for mechanical engineers: motor-driven proportional valve

Handling hot liquids can cause manufacturers to break out in a sweat, as it poses particular challenges for valve technology. That is why those who are able to keep...

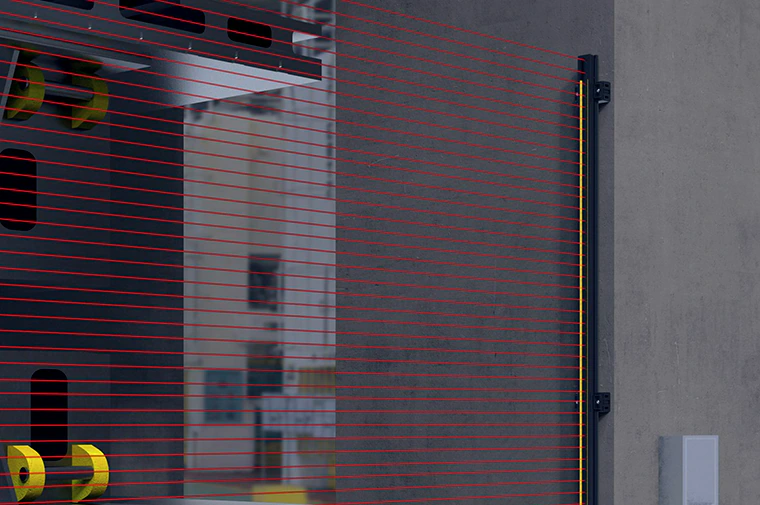

Bringing up the curtain on improved safety: New high-capacity safety light grids from Banner

Although ensuring machine safety often has no direct benefit on productivity, it is nonetheless too important to be ignored. Accidents involving personnel can have dramatic consequences for those affected...

Monitoring and visual display in a single device: The new K30 Pro optical sensor from Banner

Monitoring a process is one thing — displaying its status is another. To date, a separate device has been required for each of these two functions. Now, however, automation...

The end to loose contacts: The M12 Power Portfolio from Turck

If the power supply to a machine or plant is in jeopardy, a whole host of other things can go wrong. The risk of interruptions and failures is particularly...

Maximum precision in miniature measuring ranges: Inductive sensors with IO-Link from Turck

Measurements in micro dimensions can be too much for conventional sensors to handle. The range of measuring sensors available on the market is extremely small, especially in cases where...

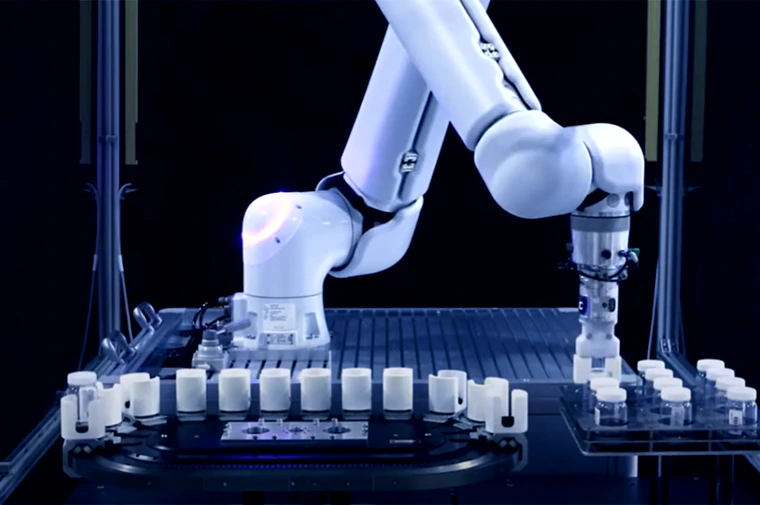

A quick team player: The Cobotta Pro collaborative robot

Whenever applications require robots and humans to collaborate, productivity usually takes a hit. This is because the safety of operating personnel must always take priority. The Cobotta Pro collaborative...

Increased energy efficiency in the compressed air system:

The operation of compressed air systems is energy intensive. This makes it all the more important to constantly control the flow rate and, if necessary, take appropriate steps to...

Lights on for increased productivity: Industrial lighting range from Banner

Even though your workplace might be filled with the brightest minds, if the lighting isn't right, the risk of mistakes and quality losses increases enormously. What's more, outdated lamps...

Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable...

Why go on long trips when you don’t have to? Remote maintenance with Cosy+ from Ewon HMS Networks

Work trips by engineers and service technicians can quickly become expensive. And it takes quite a while before the maintenance is completed or the machine defect is repaired. We...

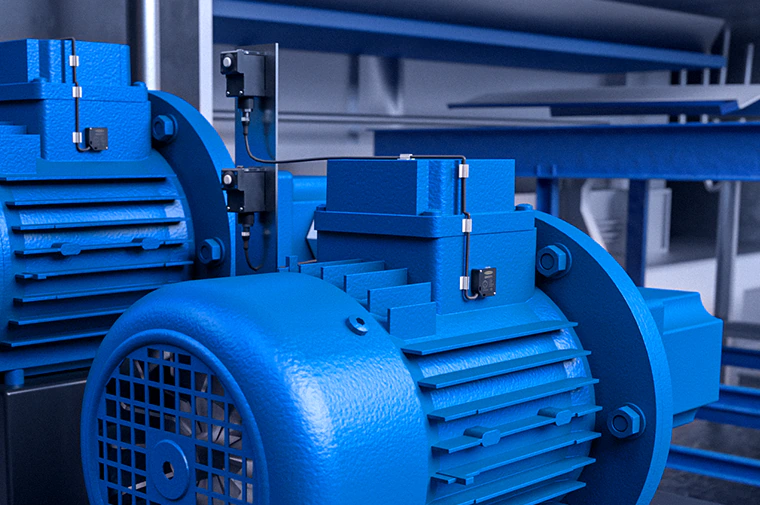

Keep a keen eye on your motors: Condition Monitoring with Turck and Banner

Before a drive gives up the ghost, it usually emits calls for help in the form of vibrations and overheating. But these are all in vain if they go...

No more wasted compressed air: Air Saver Unit from Parker

Studies show the about half of compressed air in industrial plants is lost ineffectively. Evidently, the handling of this operating supply is not very tightly monitored. However, rapidly rising...