Home > Automation technology > IP protection for peace of mind: monitoring in the control cabinet

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as heat and humidity or access by unauthorised persons. The CCM control cabinet monitor by Turck operates round the clock and sounds the alarm if a threat arises.

Hacker attacks are not the only thing that digital infrastructures need to be protected against; they are also exposed to physical risks that must be taken seriously. A critical element is the control cabinet, in which crucial functions take place. Effective protection against manipulation and other influences must therefore always be guaranteed. For the service public, which is responsible for providing support in different areas, binding national and international guidelines are in place regarding manipulation protection. For example, aspects such as power and water supply, health, nutrition or finances form the focus here. Faults or downtimes could have severe consequences in these areas.

Flat, compact and suitable for retrofittings

The CCM control cabinet monitor by Turck reliably ensures that it doesn’t come to that. It is installed in the same narrow 12.5 mm housing as the latest-generation IM12-CCM interface devices. No bigger than a pocketbook, it only takes up a small amount of space in the control cabinet and can also be stored inside the control cabinet if there is limited space. Retrofitting can be carried out at any time. A computer, special software or special tool is not required for commissioning.

Always dedicated to the issue at hand

The tireless CCM control cabinet monitor is highly sensitive. A temperature sensor, brightness sensor and humidity sensor can sense if the IP degree of protection deviates from the norm. The triangulation sensor doesn’t miss a single movement: It registers when the door is opened or has not been closed properly and triggers an alarm in the superordinate system. Manipulation cannot be prevented in every case. However, it is indicated immediately so that it can be responded to within an instant.

A monitor that forgets nothing

The device has an internal data logger and offers the option of storing measurements over a period of up to two years. The data can be called up, analysed and assessed at any time. The customary IO-Link technology is used for communication in non-explosive zones. The established HART communication is the appropriate technology in EX-zones up to zone 1.

Bachofen Ltd knows everything about the areas of application of the control cabinet monitor, particularly for tasks such as protection, separation, transformation and security. The strict requirements relating to standards require a partner who is able to offer reliable, precise and security-oriented solutions.

Downloads

Discover more control cabinet monitor

Discover more products from Turck

Areas of application

-

Universal control cabinet monitoring: from indoor IT cabinets to processing plant cabinets in the field.

Get up to speed wirelessly with the Anybus Wireless Bolt and Bachofen

-

Compact: With a structural width of 12.5 mm, the CCM devices by Turck can also be placed in small protective boxes.

-

Vigilant: CCM devices trigger an alarm if a door is opened without authorisation and show deviations in temperature and humidity.

-

Comprehensible: Thanks to the integrated data logger, the history can be called up and analysed at any time, even on non-networked devices

-

Retrofittable: CCM devices can be easily integrated in existing control cabinets and only require six connecting cables.

-

Simple: Commissioning can be carried out without a computer or special tools.

Other focus topics in the area of control technology and building technology

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Lights that speak: the new WLS27 pro-lights from Banner

When monitoring machinery, processes, actions or user behaviour, speed and clarity are paramount. The most efficient medium for these purposes is light. With its new WLS27 Pro-lights that are...

Keep a keen eye on your motors: Condition Monitoring with Turck and Banner

Before a drive gives up the ghost, it usually emits calls for help in the form of vibrations and overheating. But these are all in vain if they go...

Out into the field: CODESYS-3 controller TBEN-Lx-PLC from Turck

Some machine manufacturers are still hesitant when it comes to relocating controllers into the field, even though the benefits of decentralization are very clear. The CODESYS-3 controller TBEN-Lx-PLC from...

Anything to anything: Networking without limits

Operating downtime of machinery and systems costs money. It can be substantially reduced, however, if ideally all systems communicate with one another. Permanent networking is paving the way to...

Automation? Yes, of course!

The increasing automation of industrial processes demands reliable safeguarding of the hazardous areas surrounding machines, robots, transfer lines and automated guided vehicle systems. The safety requirements specified in the...

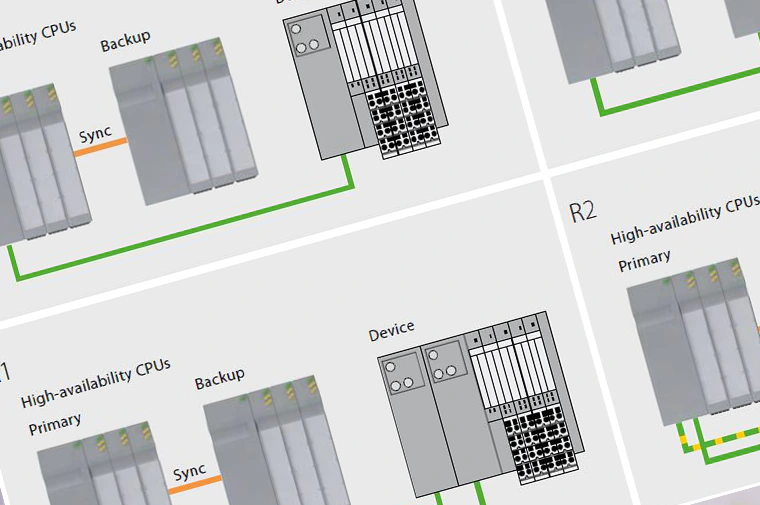

Profinet gains a foothold in process automation: S2 system redundancy now with IP67 and IP69K protection

Profinet has established itself as the communications standard for factory automation. Vehicle manufacturers and suppliers have been demonstrating the practical suitability of industrial Ethernet-based data exchange for a number...

No pressure when choose Valves: Bachofen has all you need

As building services systems become increasingly complex, so do the specific requirements for valve technology. It must be precisely tailored to the properties of the fluid to be transported...

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds...