Home > Building technology > No more shakes: with Banner vibration monitoring

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds the alarm as soon as the machine starts to shake.

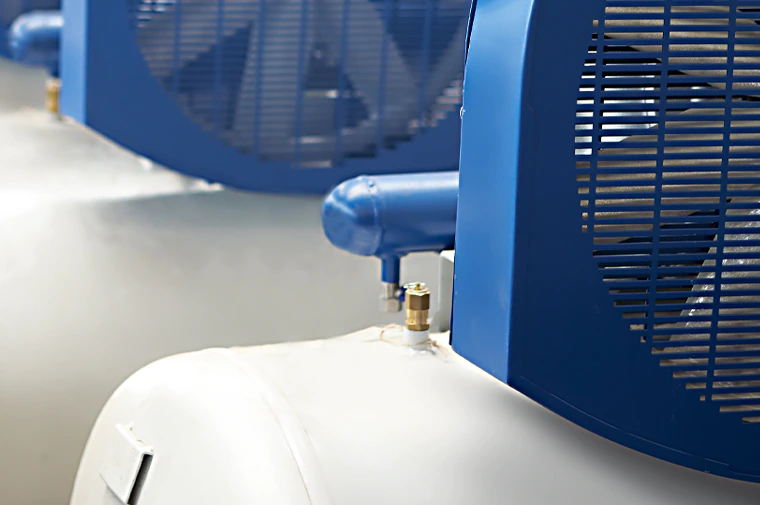

When machinery is moving, vibrations occur, especially when machines are performing heavy work, for example motors, pumps, compressors, ventilators, turbines or drives used in building technology. If the vibrations exceed a certain level, the machine must be overhauled. But how do you know when the critical point has been reached?

Measuring vibration velocity and temperature

The solution: the QM30 vibration and temperature sensor from Banner Wireless. This device measures the vibration velocity in millimetres per second and the temperature in °C. Installed as close to the bearing as possible, it will detect any increase in vibrations and heat. It is attached using a standard mounting bracket, a magnetic holder or simply with double-sided thermal-transfer adhesive tape. Thanks to the robust, IP67 zinc-alloy housing, the sensor also works perfectly in harsh environments.

Simple configuration in line with individually definable threshold values

The QM30 vibration and temperature sensor is designed for use with Banner radio transmitters such as the Q45 module or the Performance P6 module. The vibration thresholds can be configured effortlessly on the basis of ISO 10816 via DIP switches (with Q45) or configuration software (for P6 module). The sensor has a local display that shows when a threshold has been exceeded. It transfers the vibration velocity and the temperature to a gateway, which then forwards the data to a PLC or cloud.

Complete solution with up to 40 measurement points

With the Solutionskit2-Vibemetric, Banner also offers a complete solution for monitoring up to 40 measurement points. This also comes with the option to forward information to a maintenance server or a cloud.

Purchasing the QM30 vibration and temperature sensor is easy as can be; simply ask Bachofen! And if you need any replacement parts for a machine overhaul, then Bachofen is also the right place for you.

Downloads

You can find more vibration sensors in the online shop

Areas of application

-

Monitoring and maintaining machinery implants

-

Building automation

-

Energy production

Peace of mind

-

Permanent control over vibrations and operating temperature

-

Protection for machinery against damage

-

Prevention of machinery breakdowns with proactive maintenance

-

Also available in the RS485 serial communication version with Modbus RTU protocol

Other focus topics in the area of building technology

Transair compressed air distribution system: adaptable for the future

Today, production processes must increasingly be adapted to new circumstances. The building services sector is no different: flexibility is a must. The Transair® compressed air distribution system from Parker-Legris...

Tanks under control: reliable cut-out technology

When a blackwater tank has reached the maximum fill level in the sewage system of a machine or in the toilet of a train carriage and the detection system...

Stop & go in the pipes: with butterfly valves and drives from bachofen

Permanent control and precise management of the flow in pipe systems guarantees a safer process. The system must react immediately as soon as the order is given for “Valve...

Say goodbye to (compressed) air pollution: quality is guaranteed

Compressed air is an important medium that is vital in virtually every manufacturing process. However, it must be clean and supplied without losses to the individual workplaces, otherwise it...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

Reinforced for tough applications: AlfaNova stainless steel heat exchangers

With the AlfaNova, Alfa Laval produces the world’s only fully stainless steel plate heat exchanger. This is perfectly suited to applications in district heating systems and is designed to...

Personal protection: prevention thanks to building technology

The statutory provisions in the field of building technology and the construction industry specify strict guidelines when it comes to personal protection. There is a good reason for this:...

Personal safety in buildings: prevention with Mayser’s safety technology

With increasing requirements in terms of energy footprint, safety and design, automation in building technology is progressing further and further. However, automatic doors, gates and windows can still pose...

No pressure when choose Valves: Bachofen has all you need

As building services systems become increasingly complex, so do the specific requirements for valve technology. It must be precisely tailored to the properties of the fluid to be transported...

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds...

Linking factory and building automation: Intesis gateways from HMS Networks

There used to be a deep divide between information technology and operation technology. This was also a problem for building services, where automation is progressing in leaps and bounds....

It’s not worth getting mad: measurement is better

Compressed air costs money, as fast-running compressors consume expensive energy. It is therefore not just annoying when compressed air disappears into thin air but also costly in the long...

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as...

Hot and cold in alternation: a heat exchanger’s job

The principle of temperature transfer from one medium to another without direct contact between the media is used in an extremely diverse range of industrial processes. As such, the...

Don’t get pool water in your drinking water: Double-walled plate heat exchangers from Alfa Laval

In indoor and outdoor swimming pools, heat recovery from the drain water is the order of the day in terms of energy. But it also has its pitfalls. Double-walled...

Automated climate monitoring in the warehouse: Condition monitoring with Turck and Banner

When storing sensitive products, continuous temperature and humidity control is essential to prevent product losses. However, doing this manually requires a lot of effort. A complete condition monitoring solution...

Guaranteed never to leak: Transair® piping system from Parker

Leaking connections in compressed air distribution systems cause energy losses, which cost money. Due to rising energy prices, these costs are continuing to increase. The Transair® piping system from...

Fit in translation: key with babel in protocols

Confusion arises between the controllers of industrial plants and technical building systems, as they simply do not speak the same language. With the Anybus Gateways by HMS, this lack...

Durable and reliable: flow sensors from EGE

When purchasing components for building services systems, durability and low maintenance are high on the list of requirements. It’s not only annoying when a component breaks down, but also...

Coupling at the touch of a button: improved safety with Parker Rectus

Frequent changes of staff and the use of different tools are latent risk factors when it comes to connecting compressed-air lines. Thanks to the push button safety coupler from...

Cool complete solutions: with plate heat exchangers from Alfa Laval

Even the best heat exchanger will not do unless the overall system is properly designed. With Bachofen and Alfa Laval, building services engineers benefit twice over. Not only do...

Barrier-free communication: with the HMS anybus linguist

Direct connection of building automation and factory automation often used to fail due to the different protocols. But it is now possible to bridge this issue – using Anybus...

Automation? Yes, of course!

The increasing automation of industrial processes demands reliable safeguarding of the hazardous areas surrounding machines, robots, transfer lines and automated guided vehicle systems. The safety requirements specified in the...

A flexible allrounder for gateway logging: the new IXXAT® cannector from HMS Networks

As building automation advances, demands on the network structures are increasing. Communication between different systems and devices can be hampered by different bit rates and protocols. With the new...