Home > Building technology > Say goodbye to (compressed) air pollution: quality is guaranteed

Say goodbye to (compressed) air pollution: quality is guaranteed

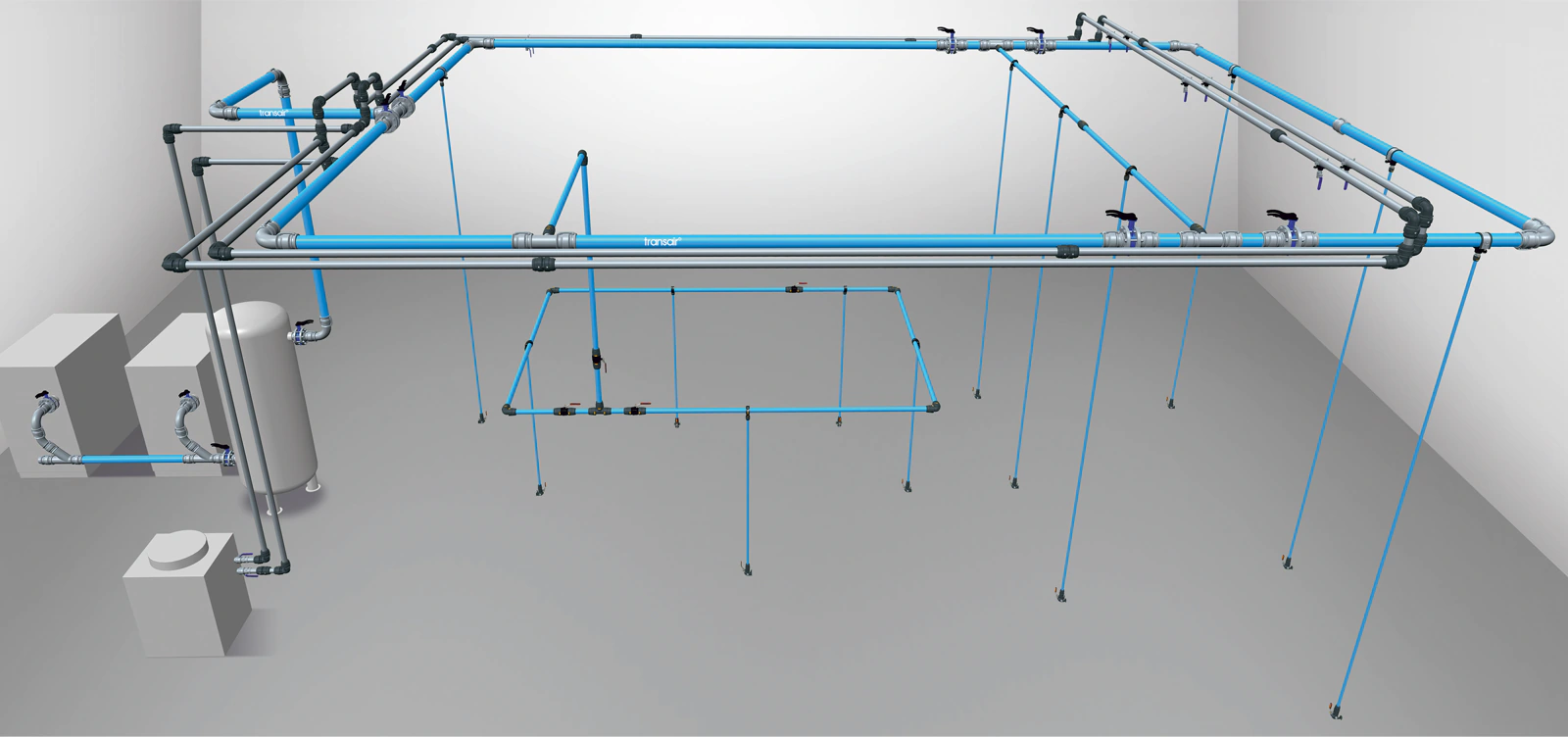

Compressed air is an important medium that is vital in virtually every manufacturing process. However, it must be clean and supplied without losses to the individual workplaces, otherwise it can prove expensive. It is therefore also worth considering quality when selecting a compressed-air distribution system. With Transair® by Parker-Legris, the air remains clean.

Compressed air is the breath of industrial production. If it becomes contaminated in any way or if the pressure reduces at a critical moment, this has a direct effect on productivity. Plant downtimes can even occur as a result of this. A typical risk factor is, for example, dirt particles, which are aspirated from the ambient air by the compressor and lead to contamination of workpieces and tools in the workplace. Corrosion in pipes and connections also proves to be an adversary of clean compressed air. Cheap systems can already show signs of damage as a result of corrosion after only a few years.

A cost-effective solution in the long term

The acquisition of a compressed-air pipe system is therefore an investment that should be made with a strong focus on quality. In this case, the better long-term solution, including in terms of costs, is a sensible decision. The Transair® system by our technology partner Parker-Legris stands for absolute air-tightness and sustainability. The pipes are made from aluminium or stainless steel, depending on their area of use. The ingenious design of the connectors and fittings ensures that not a single millilitre of air can escape from these critical contact points. As there are no narrowed areas in the entire system and the inside of the pipes have a smooth surface, free flow is ensured. This saves energy.

Versatile

However, the area of application of the system extends far beyond conveying compressed air: Transair® is also a safe solution for a vacuum from 10 mbar and inert gases such as nitrogen, argon and CO2 with a purity of up to 99.99%.

Quickly assembled and perfect for expansions

The Transair® compressed-air pipe system has over 20 years of experience under its belt. It is not only suitable for new installations but it also brings changes to manufacturing processes. Thanks to its assembly-friendly design, it can be assembled in only a short time. In the case of expansions, production can continue without interruption.

You can rely on Bachofen, even if the installation is urgent: We deliver the entire Transair® range from the warehouse and support you in implementing a solution that has been individually adapted to the process and the further general conditions.

Downloads

Discover more Transair® Services

Discover more products from Parker

Areas of application

-

Distribution of compressed air from the compressor room to the workplaces

-

Transport of compressed air, vacuum, inert gases and industrial liquids

-

New installations or replacement of existing networks in industrial plants

You will be amazed by these benefits

-

Time saving thanks to simple installation without welding, gluing or pressing

-

High flow rates with optimum sealing

-

Wide range of pipe diameters of 16.5 mm up to 168 mm

-

Flexible opportunities for expansion

-

Simple and easy to operate

Other focus topics in the area of building technology

Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable...

Hot and cold in alternation: a heat exchanger’s job

The principle of temperature transfer from one medium to another without direct contact between the media is used in an extremely diverse range of industrial processes. As such, the...

Cool complete solutions: with plate heat exchangers from Alfa Laval

Even the best heat exchanger will not do unless the overall system is properly designed. With Bachofen and Alfa Laval, building services engineers benefit twice over. Not only do...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

A flexible allrounder for gateway logging: the new IXXAT® cannector from HMS Networks

As building automation advances, demands on the network structures are increasing. Communication between different systems and devices can be hampered by different bit rates and protocols. With the new...

Durable and reliable: flow sensors from EGE

When purchasing components for building services systems, durability and low maintenance are high on the list of requirements. It’s not only annoying when a component breaks down, but also...

Distance yourself from mediocrity: the Turck uprox® 3 factor 1 sensors

Inductive sensors, for applications in special machine engineering and other demanding fields, should ideally have high switching distances, be compact and form a key element for reliable machine and...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds...

Say goodbye to (compressed) air pollution: quality is guaranteed

Compressed air is an important medium that is vital in virtually every manufacturing process. However, it must be clean and supplied without losses to the individual workplaces, otherwise it...