Home > Building technology > Durable and reliable: flow sensors from EGE

Durable and reliable: flow sensors from EGE

When purchasing components for building services systems, durability and low maintenance are high on the list of requirements. It’s not only annoying when a component breaks down, but also expensive. This will not happen with the durable and robust flow sensors from EGE.

Automation components in HVAC and refrigeration systems can be frustrating, time-consuming and expensive if they wear out quickly and require frequent maintenance. That’s why it pays to look at long-term reliability when evaluating components and to give appropriate priority to the aspect of quality. A good flow sensor should continue to show accurate values for years after installation without needing replacing or recalibration.

Thermal measurement instead of moving parts

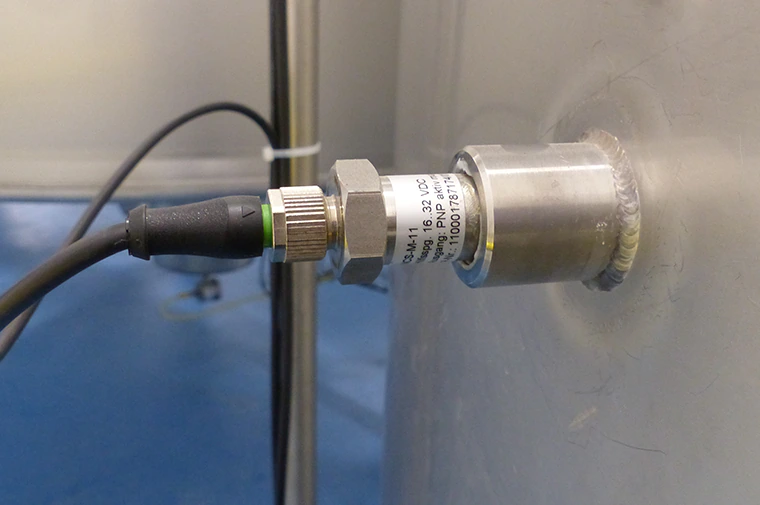

Bachofen’s technology partner EGE has put this into practice with a product concept designed for durability and reliability. The measuring system of the EGE flow sensors does not consist of mechanical parts, but is based on a thermocouple. This is safely protected in a robust housing. Even under extreme ambient conditions, these sensors continue doing their job for a long time, delivering reliable results at temperatures of up to 160 °C. They are suitable for monitoring fluids such as water, glycol mixtures or other chemicals, but also flows of air or gases.

Also suitable for aggressive fluids

The flow sensors from EGE are available in bronze alloys or stainless steels such as Hastelloy, tantalum or titanium, so that even aggressive fluids cannot harm them. The range also includes intrinsically safe, explosion-proof sensor types according to ATEX and IECx. They can be mounted in two different ways: either on the pipe with a tee or integrated in the pipe as an inline sensor.

Three different measuring principles

Depending on the requirements and the application, EGE supplies sensors which work on the calorimetric, magnetic-inductive or vortex principle. They can be set either intuitively using a potentiometer and LED display or easily programmed using buttons and a multi-segment display.

Operators of building services systems can source the entire range of EGE flow sensors from Bachofen. With expert advice of the Bachofen specialists, you can rest assured that you’ll be happy with the EGE products for years to come.

You can find more flow sensors in the online shop

Discover more products from EGE

Areas of application

-

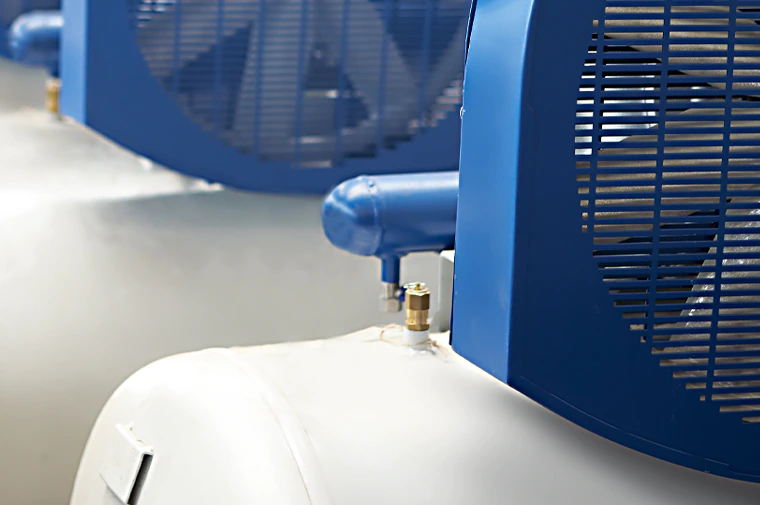

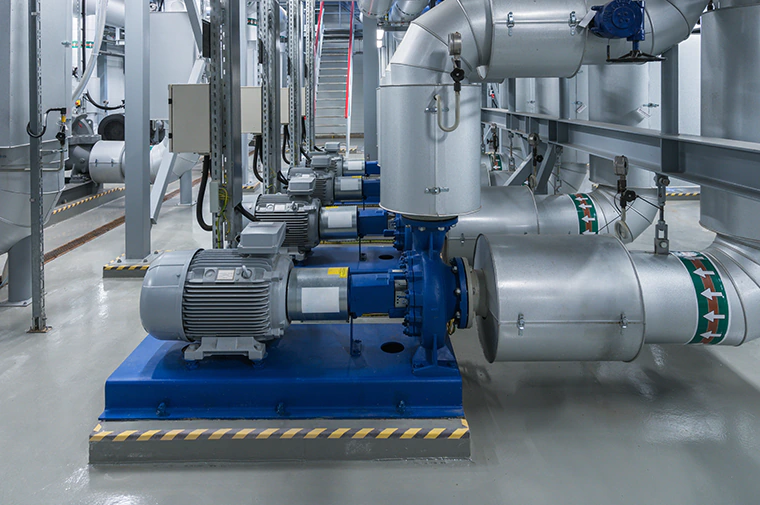

Sanitary, heating, ventilation and air conditioning systems

-

Process engineering

-

Automation industry

-

Supply systems for industrial production

Prevention is better

-

Quality made in Germany

-

Wear-free measurement without mechanical moving parts

-

Low maintenance

-

Robust and durable

-

Range includes IO-Link-compatible sensors

Other focus topics in the area of building technology

Visionary capabilities: predictive maintenance from Banner

Once machines start to vibrate, production can stall or come to a complete standstill and the costs resulting from downtime can take on astronomical proportions. Predictive maintenance using a...

Uniformity in diversity: the Turck family of fluid sensors

The world of fluid sensors is bewilderingly wide and diverse. There are countless types, features and designs that make it hard to choose the most suitable component for the...

Tanks under control: reliable cut-out technology

When a blackwater tank has reached the maximum fill level in the sewage system of a machine or in the toilet of a train carriage and the detection system...

Specially designed for work machines: the new Turck pressure transmitter PT1100/2100

The insides of work machines are exposed to harsh operating, ambient and weather conditions. Components such as pressure sensors are subject to requirements that far exceed those of applications...

So nothing flares up in production: TSM temperature sensor from Anderson Negele

Process reliability is the top priority in the food and pharmaceutical industries. Disruptions affect producers’ ability to supply and can damage their reputation. Much depends on the reliability and...

Shining a light on assembly processes: the pick-to-light solution from Banner

Making mistakes is human. Even the most reliable employee can make mistakes during commissioning and those mistakes can cause the installation process to stall, affecting productivity. Using a Pick-to-Light...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

Eagle eyes in the compressed air network: flow sensors from EGE

Compressed air is expensive. One cubic meter can easily cost 10 to 20 Swiss centimes. Too much to waste. Flow sensors from EGE with IO Link display leakages immediately...

Moving securely ahead into the future of cloud computing: data transfer using the edge gateway from Turck

Industry 4.0 is entirely dominated by the cloud, however the massive potential offered by these types of technology is still far from being exhausted. The key when it comes...

Measuring on the tank instead of in the tank: precision load cells from Anderson-Negele

Measuring content in process containers with complex shapes or in horizontal positions is not straightforward. Depending on the tank design, using conventional sensors for fill level measurements can lead...

It’s not worth getting mad: measurement is better

Compressed air costs money, as fast-running compressors consume expensive energy. It is therefore not just annoying when compressed air disappears into thin air but also costly in the long...

Integrated inline in the process: moisture measurement with Liebherr sensors

Traditional methods of moisture measurement may be justified in non-automated processes. However, these are rarely suited to use on production lines. Liebherr moisture sensors are very different. These function...

IIoT and industrie 4.0: Ewon Flexy gets you close to the action

A genuine nightmare for plant operators – a fault affects operations and, in the worst-case scenario, brings production to a standstill. You do whatever you can to rectify the...

Hot and cold in alternation: a heat exchanger’s job

The principle of temperature transfer from one medium to another without direct contact between the media is used in an extremely diverse range of industrial processes. As such, the...

Getting ahead in the world of RFID: the new UHF RFID read/write head from Turck

RFID-based applications used in materials handling and in goods logistics are many and various. Until now, it was a case of using the right reader for the right application,...

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes...

Now remotely controlled by IO-Link: Positioner 8049 from Schubert & Salzer

In plant operation, personnel deployments on site may be time-consuming and awkward in some situations. This also applies to adjusting and maintaining control valves, which are often difficult to...

Modular alarm design in variations: K100 Pro Beacon hazard indicator from Banner

It is in the nature of industrial production that it is associated with safety risks. Where hazardous substances are involved in production and processing plants, potential risks cannot be...

Increased energy efficiency in the compressed air system:

The operation of compressed air systems is energy intensive. This makes it all the more important to constantly control the flow rate and, if necessary, take appropriate steps to...

Don’t get pool water in your drinking water: Double-walled plate heat exchangers from Alfa Laval

In indoor and outdoor swimming pools, heat recovery from the drain water is the order of the day in terms of energy. But it also has its pitfalls. Double-walled...

Efficient use of space and energy: Sliding gate valve from Schubert & Salzer

Space and energy usage is becoming increasingly important when planning production plants. Space is a precious commodity and wherever energy can be saved, the opportunity should be taken. One...

So users aren’t left out in the rain: Moisture sensors from Liebherr

The moisture content of bulk materials is measured for more than just quality assurance. It is also relevant to the energy efficiency of processing operations. With the precise humidity...

Flow sensors with turck FS+: as precise as you need them to be

For many applications, the use of high-precision sensor technology is of critical importance. However, there are also many areas in which expensive technologies miss the mark. With its new...

Durable and reliable: flow sensors from EGE

When purchasing components for building services systems, durability and low maintenance are high on the list of requirements. It’s not only annoying when a component breaks down, but also...

Closely monitored fluids and gases: controllers on alert

In the chemicals and pharmaceuticals industry, plant operators are required to strictly comply with the official regulations for safety in relation to processes. The major challenges include monitoring cleaning...

Automation? Yes, of course!

The increasing automation of industrial processes demands reliable safeguarding of the hazardous areas surrounding machines, robots, transfer lines and automated guided vehicle systems. The safety requirements specified in the...