Home > Medical technology > Clean work: robotics in the clean room

Clean work: robotics in the clean room

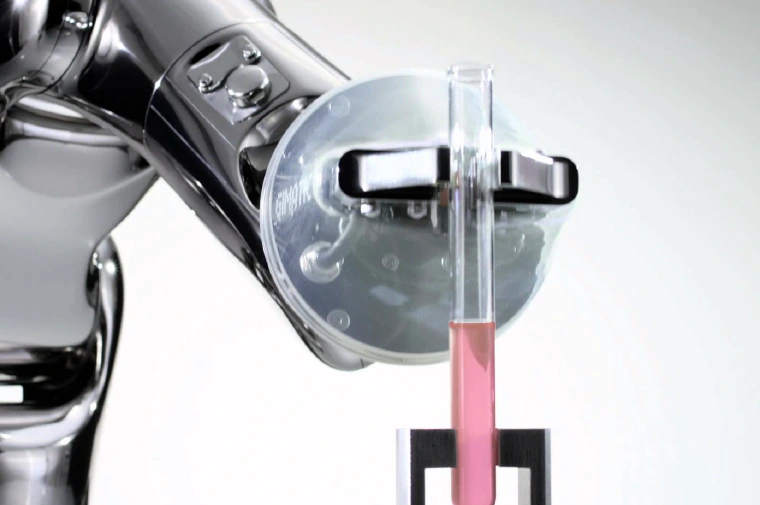

The best employees in production under clean room conditions are those who remain outside, as double door designs are complex and impede the freedom of movement of the staff. The use of robots in the clean room is therefore preferable as they meet all the strict hygiene standards for clean room production and the safety of patients is paramount in medical technical applications.

The leading global manufacturer of small robots, DENSO Robotics, has already set its sights on the demanding field of clean room production. With the VS series, Bachofen’s technology partner currently offers four types of robots, which are approved for clean rooms with ISO 5 and ISO 3 protection classes.

DENSO Robotics

The pièce de résistance is the VS H₂O₂/UV 6-axis robot. Its external characteristics are rounded corners, no visible screws and the washable, UV-resistant aluminium surface. The cables run entirely internally and are sealed at the inlets. The robot can be fitted with an external battery unit for motor coding of the robotic arms and a break release unit for the robotic arms on request. Both devices are installed outside of the clean room.

Internal wiring

All wiring is kept inside the robot to prevent cables from becomin tangled or damaged by cleaning agents.

No screws

The absence of screws means that bacteria cannot collect under the screw heads or in the threads.

Rounded edges

Streamlined forms prevent bacteria from building up in hard reach plances.

Hygienic design

The robot's outer surface is smooth and shiny, making it easy to spot and clean dirt.

Underside connector cable

The cables are connected on the underside of the robot, keeping them covered and bacteria out.

Downloads

Discover more robots

Typical areas of application

-

Medical technology, e.g. dosage, mixture of drugs

-

Research for high-tech industry, e.g. wafer handling

-

Pharmacy, e.g. automated pharmacy

The features are as convincing as the hygiene concept

-

H₂O₂/UV resistant, ISO 5 and ISO 3 protection class

-

Cycle time up to 0.33 seconds

-

Repeat accuracy up to ±0.02 mm

-

Fully-integrated cabling

Other focus topics in the area of medical technology

Ultra-small and ultra-precise: the PBG linear guide from Samick

If the available space in laboratory devices is limited, this restricts the possibilities when assessing components. Regardless of the design, huge demands are placed on precision, especially in the...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Continuous running systems: mini-format linear guidance systems

The requirement profile for moving parts in medical devices and systems for medical technical applications is dynamic: linear guidance systems must function for years without maintenance and without showing...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Ideal for the lab: PFA fluoropolyer tubing from Parker

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Effective protection for lab personnel: the new safety sensors from Turck

The extensive automation of analysis and processing in laboratories leads to increased risks for lab employees. There is a particularly high risk of injury in the case of open...

Easy rider in a compact design: miniature RSX linear guide from THK

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The...

Clean work: robotics in the clean room

The best employees in production under clean room conditions are those who remain outside, as double door designs are complex and impede the freedom of movement of the staff....

Assembly in place of an individual product: cost efficiency through outsourcing

The enormous cost pressure and increasingly tougher conditions of competition in the medical sector are also forcing machine and plant builders to rethink their supply chain and to streamline...