Home > Fluid connectors > Ideal for the lab: PFA fluoropolyer tubing from Parker

Ideal for the lab: PFA fluoropolyer tubing from Parker

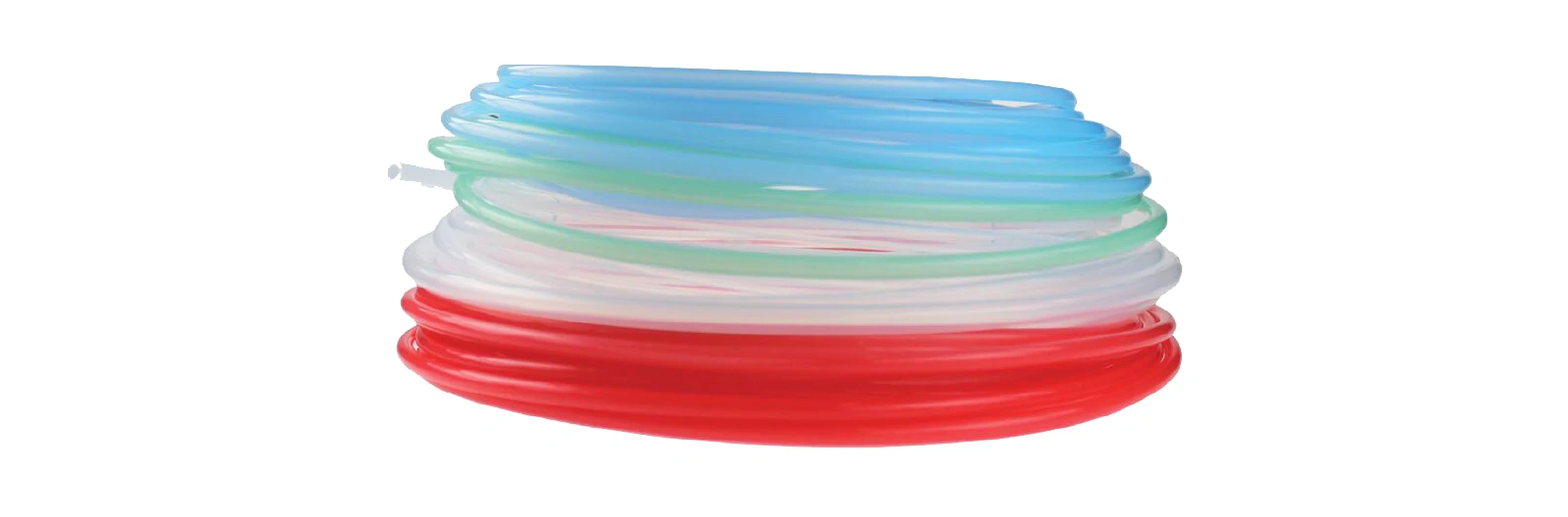

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the question of which material will offer the best properties for their specific application. Parker’s PFA fluoropolymer tubing offers the answer.

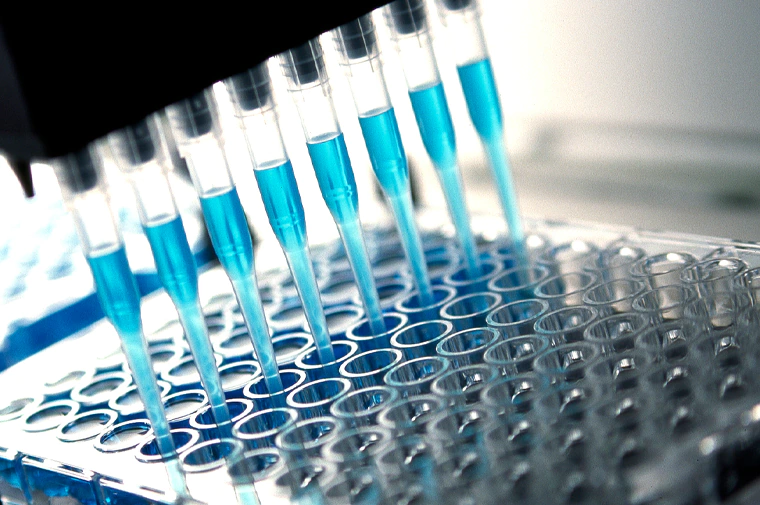

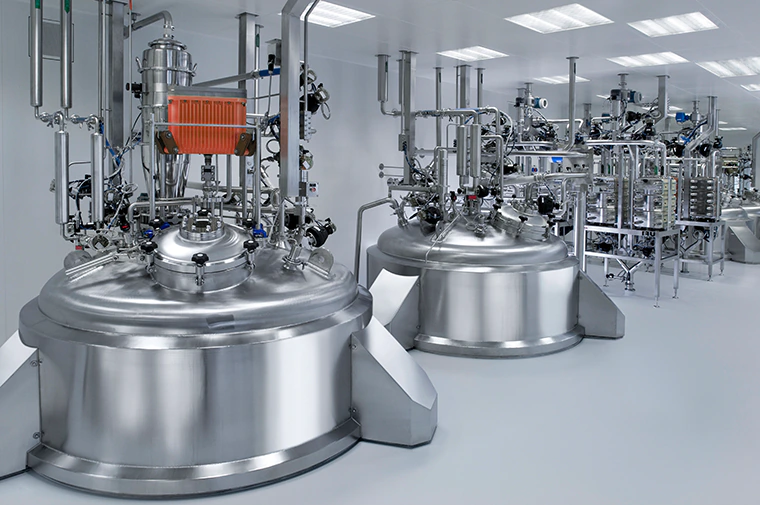

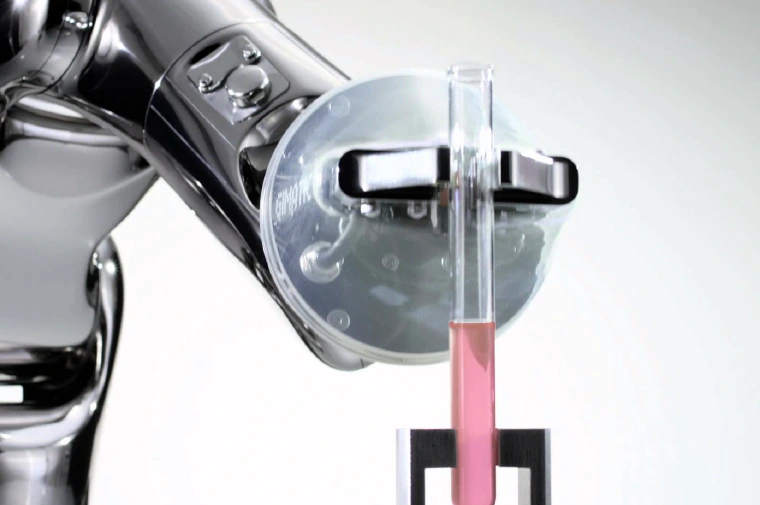

In the areas of medical technology and laboratory automation, production systems and testing and analysis equipment are sometimes placed under extreme stresses. The transport of media is subject to particularly challenging conditions. Aggressive liquids, high pressures and large temperature differences place complex and high demands on material quality. Evaluating the suitability of tubing plays an important role in the functional safety of the system as a whole and therefore warrants careful attention.

PFA – a no-compromise choice

The conventional choices for tubing are PTFE and FEP, which have specific properties to offer. PTFE tubing offers advantages primarily in terms of its chemical properties, whereas the strength of FEP tubing lies instead in its mechanical properties. This means that, depending on the application, a certain compromise is unavoidable. Those who are not willing to make such a compromise should opt for PFA tubing, which rounds off the range of tubing offered by renowned motion and control technology manufacturer Parker.

Far superior to other material types

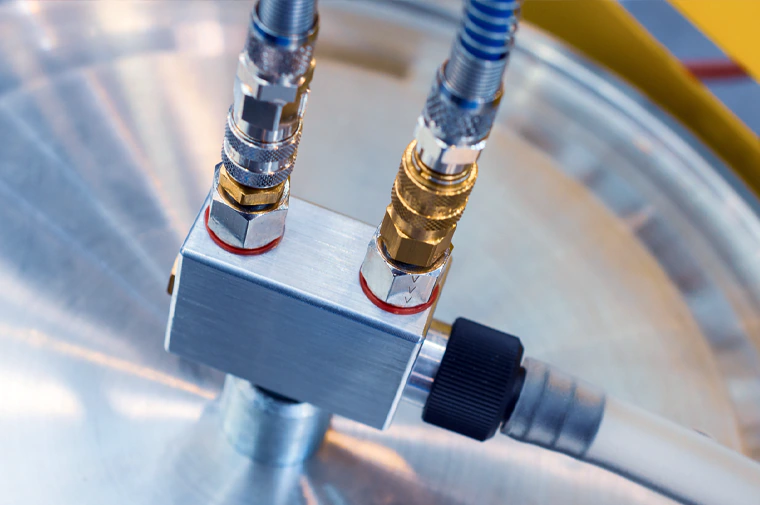

The high-purity fluoropolymer (perfluoroalkoxy) tubing from Parker Legris combines the advantages of both PTFE and FEP. It offers the best possible chemical resistance, and is readily thermoformable and translucent. It also has excellent temperature resistance and electrical properties, and can withstand high pressures. PFA tubing boasts high bending fatigue strength and is more kink-resistant than PTFE tubing. Its service life is ten times longer than other fluoropolymer tubing such as PTFE, FEP and PVDF when subjected to chemical and mechanical stresses.

Bachofen – an industry expert

The PFA tubing from Parker Legris is available in three material variants. Your choice will depend on the intended application. When making your decision, it is also important to take into account medical and industrial standards, as well as any food regulations that are applicable. Bachofen is very familiar with the areas of medical and laboratory technology, and with the food sector. You will find us to be a competent partner with whom you can discuss these issues on an equal footing.

Downloads

Buy PFA fluoropolyer tubing in shop

Discover more products from Parker Legris

Areas of application

-

Clean rooms

-

Medical devices

-

Chemical Indutry

-

Pharmaceuticals industry

-

Food industry

-

Fuel cells

-

Electronics

-

Aviation

-

Petroleum/gas industry

Stands up to any comparison

-

Excellent chemical properties

-

Flexible alternative to stainless steel pipes

-

Extremely wide temperature range, from -196°C to +260°C

-

Non-stick, making it suitable for medical and biocompatible media, foodstuffs, gas and compressed air

-

Non-flammable

-

UV-transparent

-

Silicone-free

Other focus topics in the area of medical technology

Up to the harsh conditions of the road: stainless steel couplings from Parker

The pneumatic and hydraulic systems in public transport vehicles are exposed to particularly harsh conditions, as are the lines and couplings that play a central role in these systems....

Ultra-small and ultra-precise: the PBG linear guide from Samick

If the available space in laboratory devices is limited, this restricts the possibilities when assessing components. Regardless of the design, huge demands are placed on precision, especially in the...

Transporting liquids: seeking the eco-friendly solution

The strict hygiene requirements in the industrial food production sector applies across the entire production chain. A key area of interest right now is also how to minimise your...

Transair compressed air distribution system: adaptable for the future

Today, production processes must increasingly be adapted to new circumstances. The building services sector is no different: flexibility is a must. The Transair® compressed air distribution system from Parker-Legris...

Say goodbye to (compressed) air pollution: quality is guaranteed

Compressed air is an important medium that is vital in virtually every manufacturing process. However, it must be clean and supplied without losses to the individual workplaces, otherwise it...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

Reliable means safe: ATEX-certified rotary joints

Due to the friction they create, rotating connections form one of the hazard sources in explosion-risk areas, such as in the chemicals and pharmaceuticals industry. The pre-conditions in gaseous...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Diversity and quality combined: Parker Rectus connection technology

Need to disconnect fluid connections quickly, cleanly and without any tools? Then look no further than the Rectus couplings from Parker. Parker has the right coupling for every conceivable...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Continuous running systems: mini-format linear guidance systems

The requirement profile for moving parts in medical devices and systems for medical technical applications is dynamic: linear guidance systems must function for years without maintenance and without showing...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Meets the standards and remains ecological: Parker Legris Liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the...

No uncertainty on the rails: Rectus quick-release couplings

When operating railways, each individual component must be reliable to ensure that the trains move around on schedule and without stoppages – even in adverse weather conditions. With the...

Ideal for the lab: PFA fluoropolyer tubing from Parker

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

Hot tip for pneumatic systems: non-flammable PA tubing from Parker

Standard products are not suitable for many functions in the maintenance of public transport rail and road vehicles. One important consideration, for example, is the prevention of overheating. This...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable...

Guaranteed never to leak: Transair® piping system from Parker

Leaking connections in compressed air distribution systems cause energy losses, which cost money. Due to rising energy prices, these costs are continuing to increase. The Transair® piping system from...

Effective protection for lab personnel: the new safety sensors from Turck

The extensive automation of analysis and processing in laboratories leads to increased risks for lab employees. There is a particularly high risk of injury in the case of open...

Easy rider in a compact design: miniature RSX linear guide from THK

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The...

Dry break and no dead spaces: the 200 Series coupling system from Parker

In hygiene-sensitive environments, liquid cooling is a proven means of preventing processes from overheating. However, line connections must be totally leak-proof, especially when aggressive media are involved. With Parker‘s...

Coupling at the touch of a button: improved safety with parker rectus

Frequent changes of staff and the use of different tools are latent risk factors when it comes to connecting compressed-air lines. Thanks to the push button safety coupler from...

Coupling at the touch of a button: improved safety with Parker Rectus

Frequent changes of staff and the use of different tools are latent risk factors when it comes to connecting compressed-air lines. Thanks to the push button safety coupler from...

Clean work: robotics in the clean room

The best employees in production under clean room conditions are those who remain outside, as double door designs are complex and impede the freedom of movement of the staff....

Assembly in place of an individual product: cost efficiency through outsourcing

The enormous cost pressure and increasingly tougher conditions of competition in the medical sector are also forcing machine and plant builders to rethink their supply chain and to streamline...