Home > Medical technology > Effective protection for lab personnel: the new safety sensors from Turck

Effective protection for lab personnel: the new safety sensors from Turck

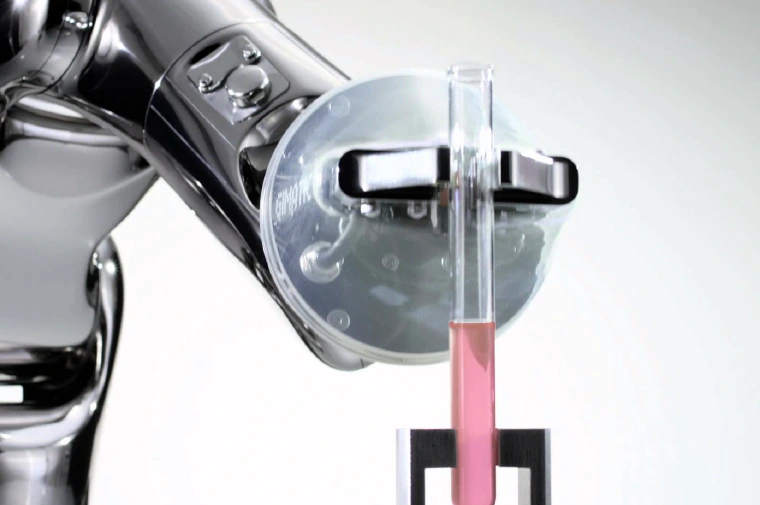

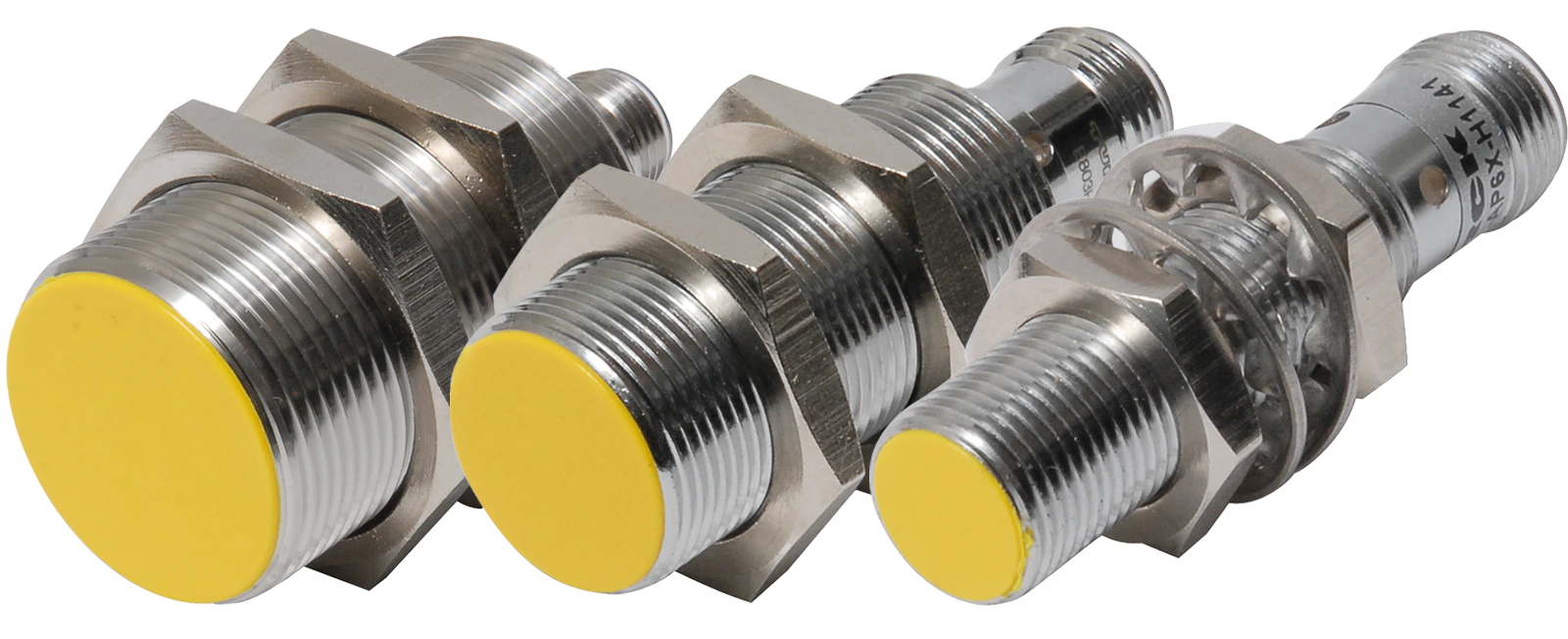

The extensive automation of analysis and processing in laboratories leads to increased risks for lab employees. There is a particularly high risk of injury in the case of open machines such as robots if these are handled in a careless way. Turck’s new inductive safety sensors react immediately to movement and eliminate any risk.

Injuries caused by machines in medical research laboratories are an unwanted side effect of lab automation. The dangers inherent in pipetting and sampling robots, dosing and gripper systems, and agitators and presses should not be underestimated. Mechanical safety switches are one possible solution. However, they require a separate actuator, which makes them complex and time-intensive to install.

Inductive sensors with two OSSD outputs for safe switch-off

Turck’s new inductive safety sensors for position and range monitoring round off the automation specialist’s already extensive portfolio of products for ensuring the safety of people and machines. The innovative components have two OSSD (output switching signal device) outputs. They operate contactlessly and therefore do not show any signs of wear even when used intensively for long periods, as is common in laboratory processes. In addition to movement, they also detect short circuits, overload and cross-circuits, thus protecting the laboratory systems from stoppages and damage. They also test switch-off capability using self-tests. Their functional safety meets the requirements of SIL 2 (IEC 61508) and performance level d (EN ISO 13849).

A clean solution in hygiene-sensitive environments

The compact design of Turck’s new safety sensors and the wide array of accessories offer ample possibilities for installation into laboratory devices of all kinds. Thanks to their large assured switch-on distances and a temperature range from -25° to +70°C, the range of applications is virtually unlimited. The sensors comply with protection class IP67, making them ideally suited for laboratory applications.

Product and application expertise included

Bachofen has long been focused on functional and machine safety. With Bachofen, you will also benefit from specific know-how regarding the use of automation components in medical and lab settings. We are thus ideally placed to offer you expert advice and help you make safe evaluation decisions.

Downloads

Discover more products from Turck

Areas of application

-

Analysis and processing devices

-

Pipetting robots

-

Liquid handling

-

Dosing and press devices

Innovative safety technology

-

High switch-off safety thanks to two OSSD outputs

-

Compliant with standards up to SIL 2 and performance level d

-

Simple to install thanks to large mechanical tolerances

-

Large assured switch-on distance; no separate actuator required

-

Wear-free and low-maintenance

-

Protection class IP67 for high machine availability

Other focus topics in the area of medical technology

Guard duty on the ramp: BANNER vehicle detection

Open gates are somewhat inviting. Unfortunately that is also the case for unauthorised people. Previously it was commonplace to employ gatekeepers who kept an eye on the comings and...

Ultra-small and ultra-precise: the PBG linear guide from Samick

If the available space in laboratory devices is limited, this restricts the possibilities when assessing components. Regardless of the design, huge demands are placed on precision, especially in the...

Reliable final inspections: eagle-eyed error detection

Packaging and labelling processes used in the food industry are mainly geared towards processing materials quickly. Final inspections take even greater precedence. These must be performed without any hitch...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds...

Continuous running systems: mini-format linear guidance systems

The requirement profile for moving parts in medical devices and systems for medical technical applications is dynamic: linear guidance systems must function for years without maintenance and without showing...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Keeping an eye on the tank: L3 pressure transmitter from Anderson-Negele

If you cannot see what is going on inside tanks in food or pharmaceutical production, the processes are almost impossible to control. To ensure process reliability, the tank contents...

Distance yourself from mediocrity: the Turck uprox® 3 factor 1 sensors

Inductive sensors, for applications in special machine engineering and other demanding fields, should ideally have high switching distances, be compact and form a key element for reliable machine and...

Ideal for the lab: PFA fluoropolyer tubing from Parker

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Safe procedures for machine operation: Turck CMVT-QR20 vibration and temperature sensor

The operation of rotating machines causes vibrations that can cause problems. Excessive temperatures are another risk factor. The CMVT-QR20 vibration and temperature sensor from Turck detects when it becomes...

The safe alternative to the Zener barrier: ATEX-compatible IMX12-SG strain gauge evaluation device from Turck

Strain gauge evaluation devices for use in ATEX zones are a rarity. The divide between ATEX and non-ATEX areas is particularly critical. With the IMX12-SG interface, Turck has unveiled...

External linear scale now a thing of the past: the new THK SHS-LE linear guide

In mechanical engineering, complex component-installation steps combined with a notable lack of space remains an ongoing challenge. In addition to being more space-saving in its design, the new THK...

Encoders for mobile machinery: the Turck mini holds tight

Automation in vehicle construction is like a rally course littered with obstacles – mobile applications place much higher demands on automation components than traditional industrial applications. With the compact,...

Effective protection for lab personnel: the new safety sensors from Turck

The extensive automation of analysis and processing in laboratories leads to increased risks for lab employees. There is a particularly high risk of injury in the case of open...

Easy rider in a compact design: miniature RSX linear guide from THK

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The...

Clean work: robotics in the clean room

The best employees in production under clean room conditions are those who remain outside, as double door designs are complex and impede the freedom of movement of the staff....

Non-contact precision measurement: Turck DR series radar distance sensors

There are a variety of processes where measurements can only be taken reliably and safely at a distance. Harsh environments are an example of these. Factors internal to the...

At home in ATEX atmospheres: LC500 series air flow controllers from EGE

Monitoring air flows has been an essential safety element in the operation of plant and machinery for many years. If this occurs in ATEX zones, the flow controllers used...

Assembly in place of an individual product: cost efficiency through outsourcing

The enormous cost pressure and increasingly tougher conditions of competition in the medical sector are also forcing machine and plant builders to rethink their supply chain and to streamline...