Home > Customer-specific solutions > Assembly in place of an individual product: cost efficiency through outsourcing

Assembly in place of an individual product: cost efficiency through outsourcing

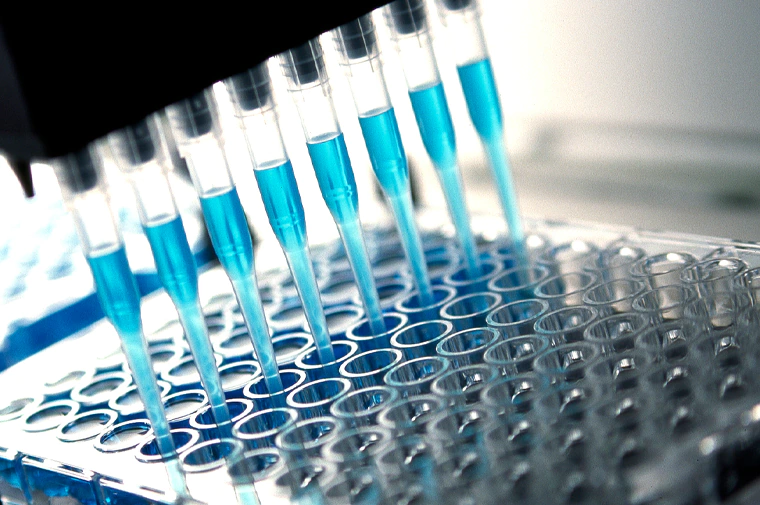

The enormous cost pressure and increasingly tougher conditions of competition in the medical sector are also forcing machine and plant builders to rethink their supply chain and to streamline their structures. This is usually the result of a stabilisation of the market position and a strengthening of competitiveness.

Aiming towards the outsourcing of parts of the machinery and equipment production, which are not directly related to the company’s core competencies, e.g. engineering and installation of assemblies.

We turn individual parts into your complete solution

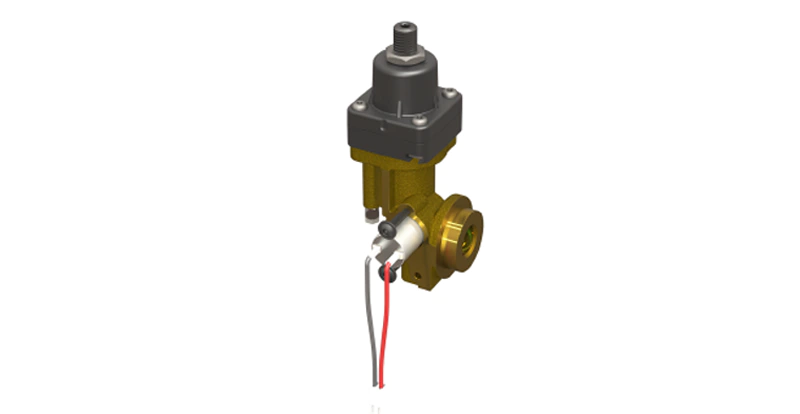

For example, the installation of an assembly is necessary to allow optimal and energy-efficient control and regulation of the heating circuit in the steam generator of a steriliser. Areas of application of these solutions in medical technology are e.g. sterilisers, autoclaves in the dental trade and medical instrumentation engineering.

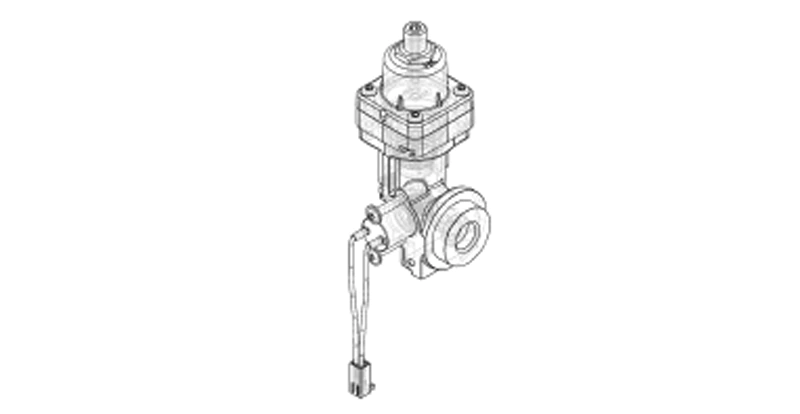

Screw connection

Parker Lucifer lolenoid valve

Liquipure NW4

Flow restrictor

O-rings

(not visible)

Flow controller

(not visible)

Ball valve

Nickel-plated brass elbow connector

Enlargement nipple

R ¼'' - G ½''

Alfa Laval plate heat exchanger

brazed

Parker Lucifer solenoid valve

Liquipure NW2

Enlargement nipple R

R ¼'' - G ½''

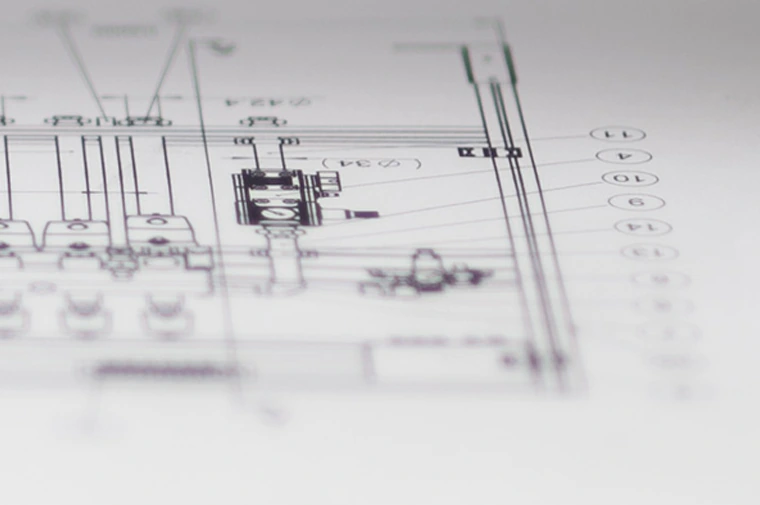

Developed according to your specifications

Outsourcing of the process to Bachofen simplifies the procurement process enormously. Processing is carried out with a supplier, a contact person and an item number. The result is a customer-specific, ready-to-install solution.

Development and construction on the basis of your specific requirements.

Detailed development of the ready-to-install solution using CAD. All from a single source.

For example, the installation of an assembly is necessary so that a cooling and heating circuit in the steam generator of a steriliser can be controlled and regulated. It consists of eleven individual customer-specific products, such as heat exchangers, solenoid valves, ball valves and flow limiters, which Bachofen has developed, installed and supplied as a ready-for-use solution.

Discover more customer specific solutions

Your added value with outsourcing of your process

-

The power of innovation, customer proximity, short response times

-

Saving time and resources: Bachofen takes over the planning, development, documentation, manufacturing, installation and testing

-

Simplified processing: The procurement and administration of individual items is no longer required

-

Reduction in the number of suppliers (tier-one supplier)

-

Reduction in complexity and avoidance of incorrect installations

-

Several functions in an extremely confined space

-

Complete range of standard/special components

Downloads

Other focus topics in the area of medical technology

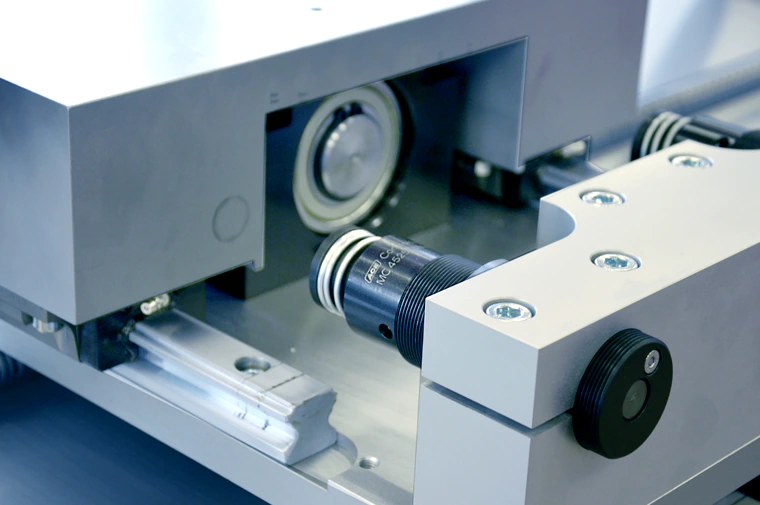

Ultra-small and ultra-precise: the PBG linear guide from Samick

If the available space in laboratory devices is limited, this restricts the possibilities when assessing components. Regardless of the design, huge demands are placed on precision, especially in the...

Solutions and expertise to meet your needs: Bachofen Engineering

As a rule, manufacturers come under a lot of pressure in terms of time, costs and innovations. And on top of that, they are faced with consistently high customer...

Save instead of fishing in murky water: turbidity sensor ITM-51 from Anderson-Negele

Inaccurate phase separation in the food production industry leads to product losses, which quickly become expensive. These losses can be significantly reduced by switching at the right moment. With...

Product identification with “all-in-one RFID”: the new PD67 RFID handheld from Turck

In the field of medicines and pharmaceuticals, it is a mandatory legal requirement for products to be identified and for all of the manufacturing and processing to be traceable....

Pharmaceutical production: no opportunity for pirates

Fake is on the advance. Even the pharmaceutical industry has to fight against copies and counterfeits. One effective measure is seamless product identification across the entire production and distribution...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Continuous running systems: mini-format linear guidance systems

The requirement profile for moving parts in medical devices and systems for medical technical applications is dynamic: linear guidance systems must function for years without maintenance and without showing...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Ideal for the lab: PFA fluoropolyer tubing from Parker

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

Hot tip for mechanical engineers: motor-driven proportional valve

Handling hot liquids can cause manufacturers to break out in a sweat, as it poses particular challenges for valve technology. That is why those who are able to keep...

Good spirits in the background: THK miniature guides

In the medical and health industries, reliable helpers are indispensable. Unseen in the background, they ensure that everything runs smoothly: conscientious, persevering and without ever showing any signs of...

Effective protection for lab personnel: the new safety sensors from Turck

The extensive automation of analysis and processing in laboratories leads to increased risks for lab employees. There is a particularly high risk of injury in the case of open...

Easy rider in a compact design: miniature RSX linear guide from THK

Some sectors, such as medical and laboratory technology, call for compact devices and machines. Mechanical engineers are therefore increasingly shifting their focus to the space requirements of components. The...

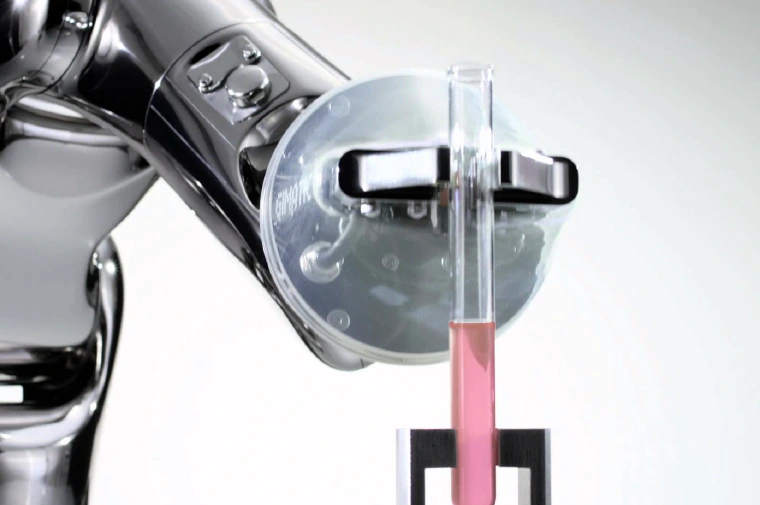

Clean work: robotics in the clean room

The best employees in production under clean room conditions are those who remain outside, as double door designs are complex and impede the freedom of movement of the staff....

Assembly in place of an individual product: cost efficiency through outsourcing

The enormous cost pressure and increasingly tougher conditions of competition in the medical sector are also forcing machine and plant builders to rethink their supply chain and to streamline...