Home > Building technology > It’s not worth getting mad: measurement is better

It’s not worth getting mad: measurement is better

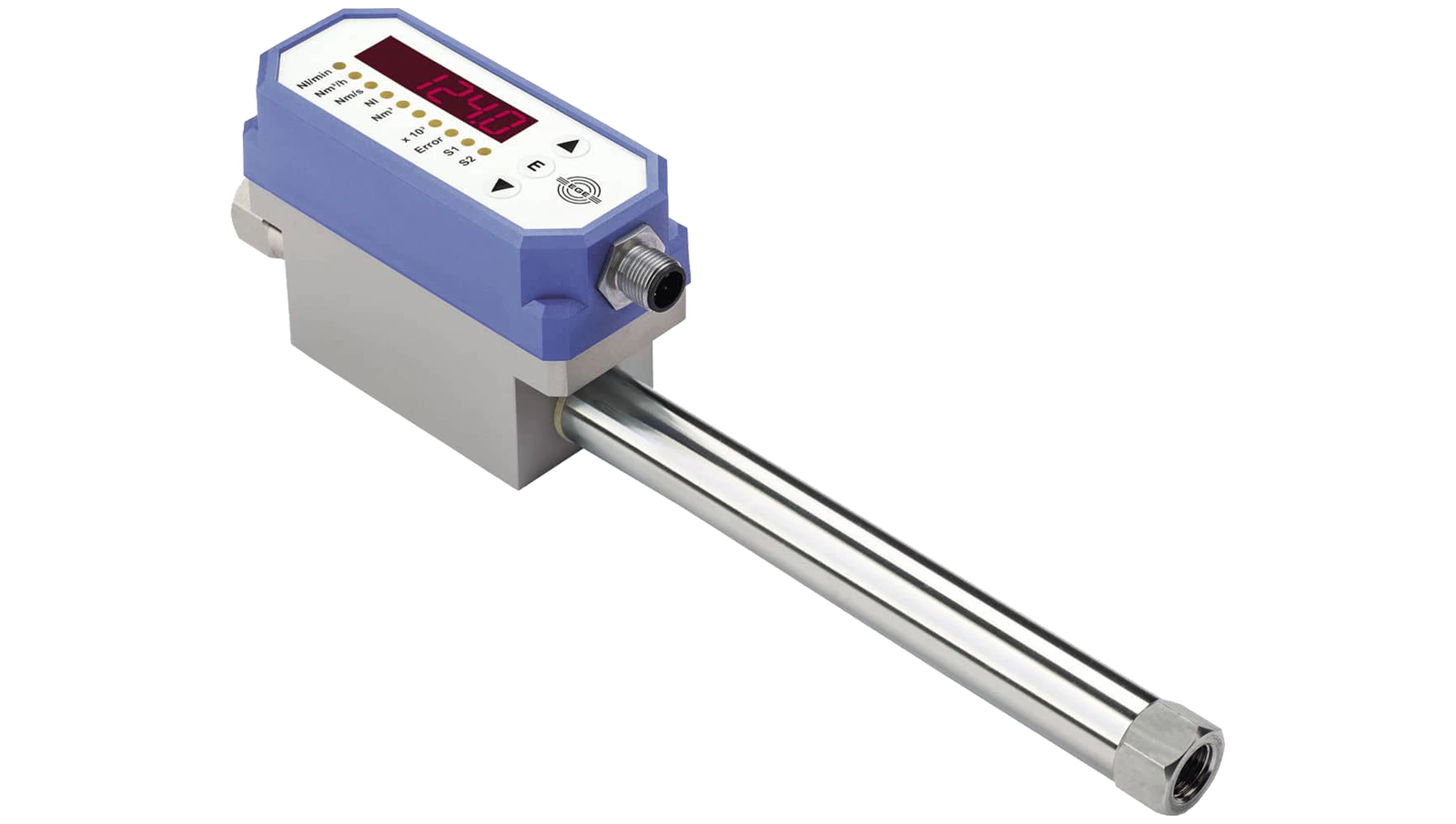

Compressed air costs money, as fast-running compressors consume expensive energy. It is therefore not just annoying when compressed air disappears into thin air but also costly in the long term. The compressed-air measuring device LDN 1000 by EGE detects minimal losses and makes it possible to control the entire compressed-air system with minimum cost.

The compressed-air measuring device by our technology partner EGE-Elektronik GmbH measures compressed-air consumption, flow rate and temperature with the highest level of accuracy and acts as a detection device and control centre at the same time.

Detecting even the smallest leaks

As a detection device, it has the capability of detecting even the smallest leaks in compressed-air systems with large dimensions. This helps the plant operator to locate leaks and remedy these. The device also shows which compressed-air volumes are drawn off by individual work stations or departments. In this way, compressed-air consumption can be suitably divided up and assigned to the different cost centres proportionally.

Optimisation of compressed-air consumption

The LDN 1000 compressed-air measuring device is also meticulous when used as a control centre. With smart functions such as calculating total usage, dosage, temperature measurement, hysteresis and off-delay, the operation of the entire system is based around efficiency and carrying out comprehensive inspections. In the display, a sensor shows the compressed-air consumption of the connected areas, plant parts or tools.

Simple parameterisation on a PC or laptop

In addition to the front sensor buttons, the LDN 1000 is equipped with an IO-Link interface. Users can select the measurements directly using the PLC and parameterise the device with ease on their PC or laptop. Manipulation detection is available as an option for each non-resettable modification counter. It is also possible to adapt the scope of operation for various user groups.

Tolerance = 1% of the measurement range value at most

The device that should be used depends on the pipe diameter. Another factor is the minimum and maximum flow quantity. This can be between 0.04 Nm3/h and 750 Nm3/h. The maximum deviation is never more than 1% of the measurement-range end value in either variant. With Bachofen, the choice to make is a breeze. Simply let us know the benchmarks and we will calculate and determine the optimum measurement method for you.

Downloads

- EGE, LDN 1009

- EGE, LDS 1000

- EGE, LDV 1000

Discover more compressed-air measuring device

Discover more products from EGE

Areas of application

-

Mass flow measurement of compressed air

-

Consumption measurement in compressed air networks

-

Leak detection

-

Itemisation in consumption ratios according to cost centres

Cost-conscious plant engineers are lost for words

-

Simple assembly

-

Precise measurement

-

Comfortable adjustment via IO-Link interface

-

Several user levels can be configured

-

Manipulation detection

Other focus topics in the area of measurement / process technology and building technology

Specially designed for work machines: the new Turck pressure transmitter PT1100/2100

The insides of work machines are exposed to harsh operating, ambient and weather conditions. Components such as pressure sensors are subject to requirements that far exceed those of applications...

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds...

So users aren’t left out in the rain: Moisture sensors from Liebherr

The moisture content of bulk materials is measured for more than just quality assurance. It is also relevant to the energy efficiency of processing operations. With the precise humidity...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as...

Closely monitored fluids and gases: controllers on alert

In the chemicals and pharmaceuticals industry, plant operators are required to strictly comply with the official regulations for safety in relation to processes. The major challenges include monitoring cleaning...

One IP address for an entire sub-network: all thanks to beep from Turck

With the TBEN-S, TBEN-L and FEN20 fieldbus modules, Turck is opening up new possibilities for machine and plant manufacturers. Each device on a network can be reached via an...

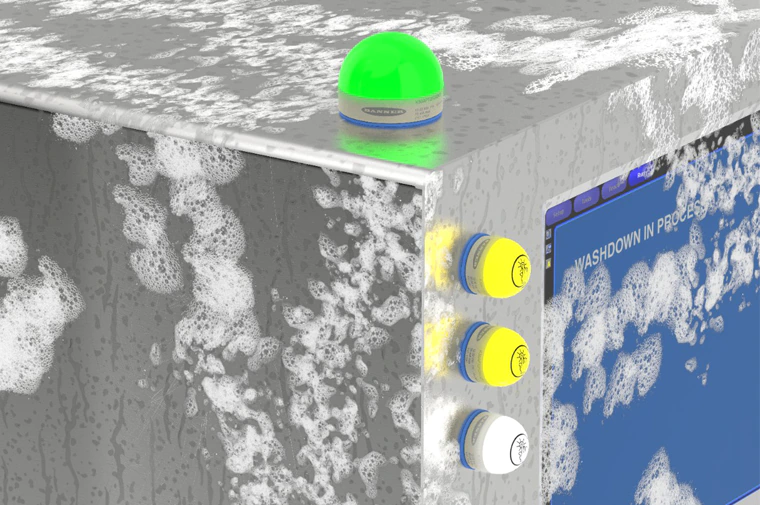

Bright minds: Banner K50 Pro touch buttons

The easier it is to control and visualise a machine or plant, the higher its efficiency and the lower the error rate. The K50 Pro touch buttons from Banner...

Automation? Yes, of course!

The increasing automation of industrial processes demands reliable safeguarding of the hazardous areas surrounding machines, robots, transfer lines and automated guided vehicle systems. The safety requirements specified in the...

Transair compressed air distribution system: adaptable for the future

Today, production processes must increasingly be adapted to new circumstances. The building services sector is no different: flexibility is a must. The Transair® compressed air distribution system from Parker-Legris...