Home > Building technology > Transair compressed air distribution system: adaptable for the future

Transair® compressed air distribution system: adaptable for the future

Today, production processes must increasingly be adapted to new circumstances. The building services sector is no different: flexibility is a must. The Transair® compressed air distribution system from Parker-Legris has been designed to allow for effortless expansion or conversion at any time.

Flexibility is increasingly becoming an important competitive advantage in industrial production. An adaptable production infrastructure is essential for companies to be able to react to market changes in good time, and building service plants are no exception.

Safe and future-proof

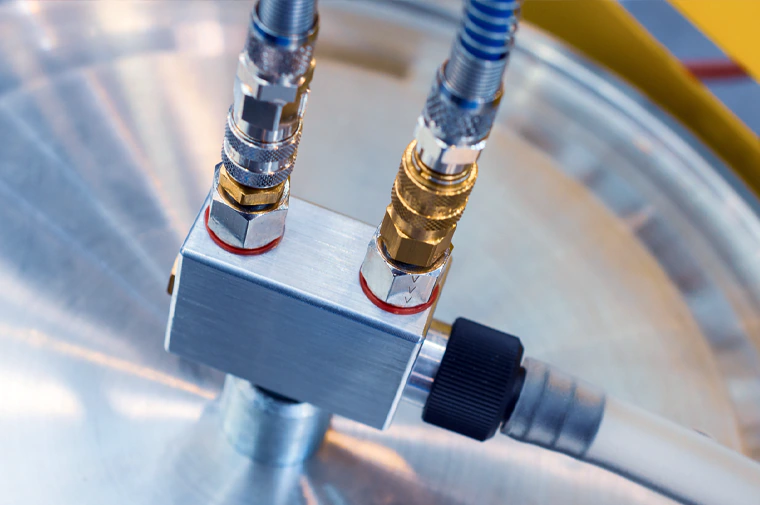

The Transair® system allows plant manufacturers in the field of compressed air distribution to ready their customers for future developments. Unlike other distribution systems, Transair® is easy to assemble, disassemble and adapt to new situations at any time, with no costly tool requirements. What’s more, it is user-friendly and offers almost limitless flexibility.

Planning ease with Building Information Modelling (BIM)

To simplify project team collaboration, an electronic BIM platform can now be use to plan and design the Transair® system, allowing team members to develop the project together, work out alternative planning scenarios and run simulations.

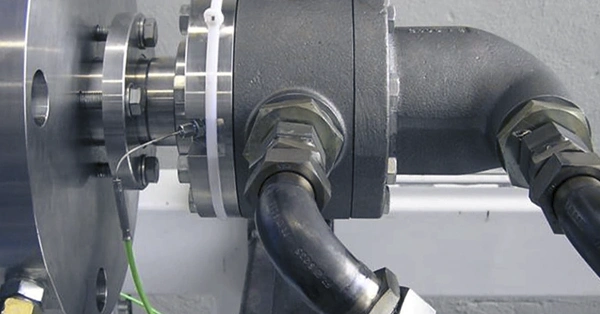

New range of parts for the compressor room

The compressor room houses the beating heart of the compressed air system. For this area alone, Transair® now offers a specially tailored range of parts that primarily includes T, L and cross connectors. Kits containing the required components to connect the devices in the compressor room are also available for common pipe diameters 63 mm, 76 mm, 100 mm and 168 mm.

Transair® from Parker-Legris is designed to develop as customer requirements change, ensuring constantly high system reliability. With products from Transair® and expert advice from Bachofen, users are in safe hands and can effectively avoid costly compressed air losses.

Downloads

You can find more Parker Transair® in the online shop

Discover more products from Parker

Areas of application

-

Distribution of compressed air from the compressor room to the workplaces

-

Transport of compressed air, vacuum, inert gases and industrial liquids

-

New installations or replacement of existing networks in industrial plants

Not just full of compressed air

-

Time saving thanks to simple installation without welding, gluing or pressing

-

High flow rates with optimum sealing

-

Wide range of pipe diameters of 16.5 mm up to 168 mm

-

Flexible expansion options Simple and easy to operate

-

New: products available on the BIM e-platform

-

New: specially tailored range of parts for the compressor room

-

Simple and easy to operate

Other focus topics in the area of building technology

Up to the harsh conditions of the road: stainless steel couplings from Parker

The pneumatic and hydraulic systems in public transport vehicles are exposed to particularly harsh conditions, as are the lines and couplings that play a central role in these systems....

Transporting liquids: seeking the eco-friendly solution

The strict hygiene requirements in the industrial food production sector applies across the entire production chain. A key area of interest right now is also how to minimise your...

Transair compressed air distribution system: adaptable for the future

Today, production processes must increasingly be adapted to new circumstances. The building services sector is no different: flexibility is a must. The Transair® compressed air distribution system from Parker-Legris...

Tanks under control: reliable cut-out technology

When a blackwater tank has reached the maximum fill level in the sewage system of a machine or in the toilet of a train carriage and the detection system...

Stop & go in the pipes: with butterfly valves and drives from bachofen

Permanent control and precise management of the flow in pipe systems guarantees a safer process. The system must react immediately as soon as the order is given for “Valve...

Say goodbye to (compressed) air pollution: quality is guaranteed

Compressed air is an important medium that is vital in virtually every manufacturing process. However, it must be clean and supplied without losses to the individual workplaces, otherwise it...

Safe pipe system: clean compressed air

Compressed air plays a key role in almost all production processes. Leaks in the system lead to production losses with the related consequential costs. As a manufacturer of quality...

Reliable means safe: ATEX-certified rotary joints

Due to the friction they create, rotating connections form one of the hazard sources in explosion-risk areas, such as in the chemicals and pharmaceuticals industry. The pre-conditions in gaseous...

Reinforced for tough applications: AlfaNova stainless steel heat exchangers

With the AlfaNova, Alfa Laval produces the world’s only fully stainless steel plate heat exchanger. This is perfectly suited to applications in district heating systems and is designed to...

Personal protection: prevention thanks to building technology

The statutory provisions in the field of building technology and the construction industry specify strict guidelines when it comes to personal protection. There is a good reason for this:...

Personal safety in buildings: prevention with Mayser’s safety technology

With increasing requirements in terms of energy footprint, safety and design, automation in building technology is progressing further and further. However, automatic doors, gates and windows can still pose...

Diversity and quality combined: Parker Rectus connection technology

Need to disconnect fluid connections quickly, cleanly and without any tools? Then look no further than the Rectus couplings from Parker. Parker has the right coupling for every conceivable...

Meets the standards and remains ecological: parker legris liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

No pressure when choose Valves: Bachofen has all you need

As building services systems become increasingly complex, so do the specific requirements for valve technology. It must be precisely tailored to the properties of the fluid to be transported...

No more shakes: with Banner vibration monitoring

Excessive vibrations can damage machines and in some cases lead to operational stoppages. Vibrations often occur as a result of worn or loose parts. The Banner vibration sensor sounds...

Connected to health: Parker Rectus connection technology

Regulators consistently prescribe new guidelines and standards to the players in the fields of medical technology and biotechnology. These guidelines and standards are compatible if the system manufacturers can...

Meets the standards and remains ecological: Parker Legris Liquifit

In branches of industry where hygiene is critical, there is no escape from Machinery Directive 2006/42/EC. The keen eye of the legislator is trained in particular on components that...

Linking factory and building automation: Intesis gateways from HMS Networks

There used to be a deep divide between information technology and operation technology. This was also a problem for building services, where automation is progressing in leaps and bounds....

Pushing in fast beats screwing in slowly: Carstick+ push-to-connect cartridge from Parker

Finding space- and time-saving solutions is becoming increasingly important in equipment manufacturing. This applies to all areas of the process. Parker has enhanced the Carstick® push-in cartridge for the...

It’s not worth getting mad: measurement is better

Compressed air costs money, as fast-running compressors consume expensive energy. It is therefore not just annoying when compressed air disappears into thin air but also costly in the long...

No uncertainty on the rails: Rectus quick-release couplings

When operating railways, each individual component must be reliable to ensure that the trains move around on schedule and without stoppages – even in adverse weather conditions. With the...

IP protection for peace of mind: monitoring in the control cabinet

The heart of IT systems lies in the control cabinet. This means that it is even more important to ensure that it is protected against physical influences such as...

Ideal for the lab: PFA fluoropolyer tubing from Parker

Laboratory systems need to meet many different requirements. This applies not only to the equipment itself, but also to accessories such as tubing. Equipment manufacturers are faced with the...

Hygiene in the clean room: clean connection technology

For applications in medical technology and clean industrial production systems, connectors must comply with the most up-to-date industry-specific standards with regard to hygiene. In order to avoid the risk...

Hot tip for pneumatic systems: non-flammable PA tubing from Parker

Standard products are not suitable for many functions in the maintenance of public transport rail and road vehicles. One important consideration, for example, is the prevention of overheating. This...

Hot and cold in alternation: a heat exchanger’s job

The principle of temperature transfer from one medium to another without direct contact between the media is used in an extremely diverse range of industrial processes. As such, the...

Perfect for sustainability: Compressed air blow guns from Parker Legris

Cleaning with compressed air is fast and effective. But what about the energy usage? Parker Legris compressed air blow guns are fully in line with the trend towards sustainable...

Don’t get pool water in your drinking water: Double-walled plate heat exchangers from Alfa Laval

In indoor and outdoor swimming pools, heat recovery from the drain water is the order of the day in terms of energy. But it also has its pitfalls. Double-walled...

Automated climate monitoring in the warehouse: Condition monitoring with Turck and Banner

When storing sensitive products, continuous temperature and humidity control is essential to prevent product losses. However, doing this manually requires a lot of effort. A complete condition monitoring solution...

Guaranteed never to leak: Transair® piping system from Parker

Leaking connections in compressed air distribution systems cause energy losses, which cost money. Due to rising energy prices, these costs are continuing to increase. The Transair® piping system from...